Spraying direction adjustable inclined hole fuel injector adapter device

A technology of injection direction and fuel injector, which is applied to fuel injection devices, measuring devices, instruments, etc. to achieve good cooling effect and facilitate image processing and analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

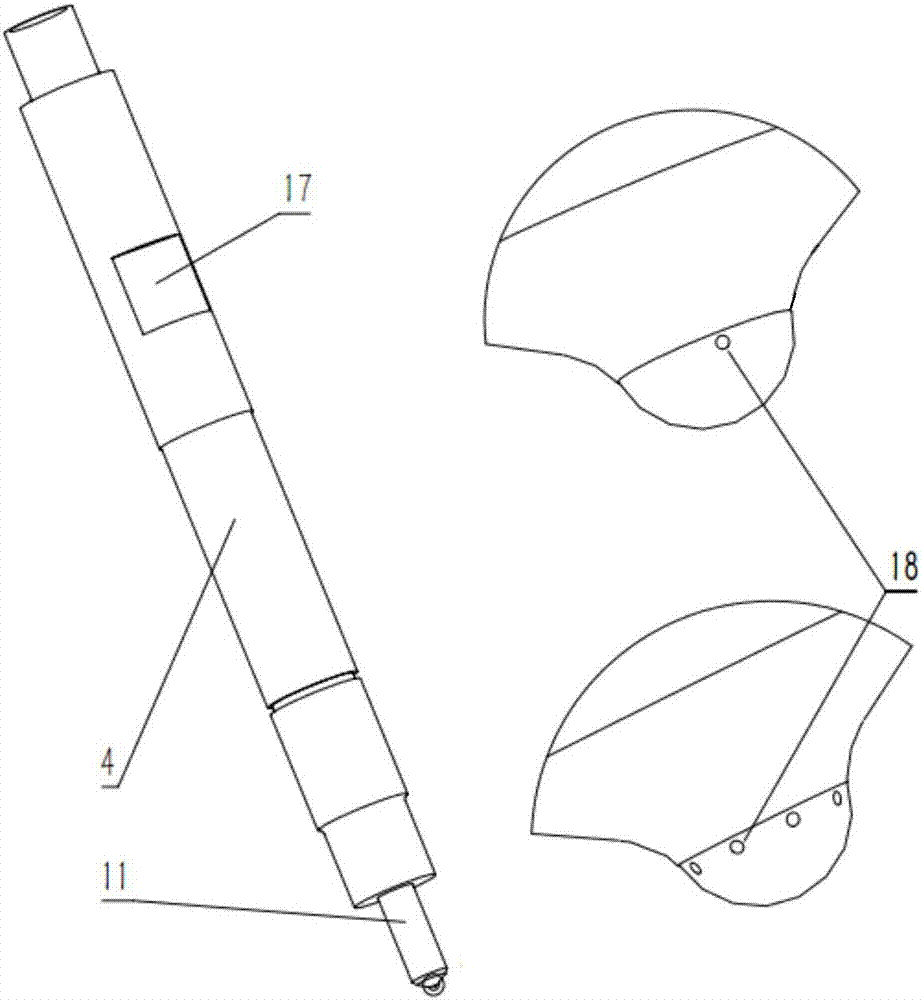

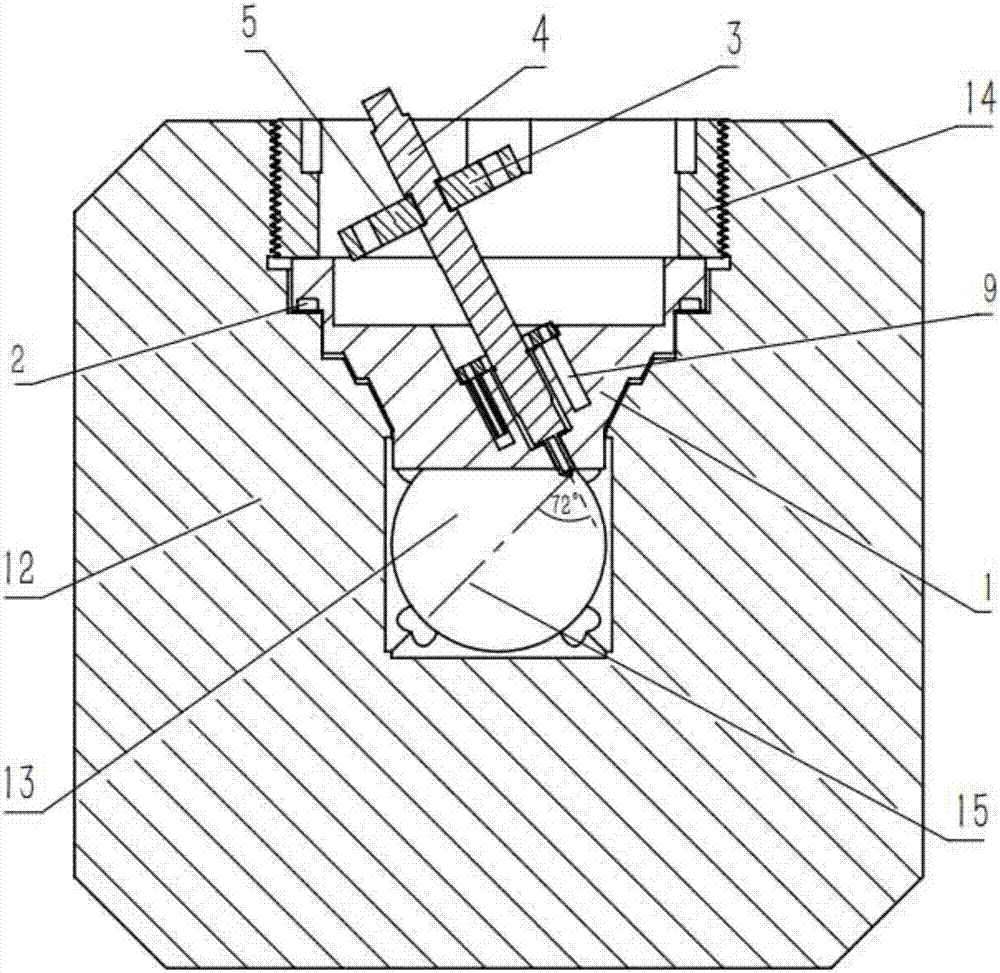

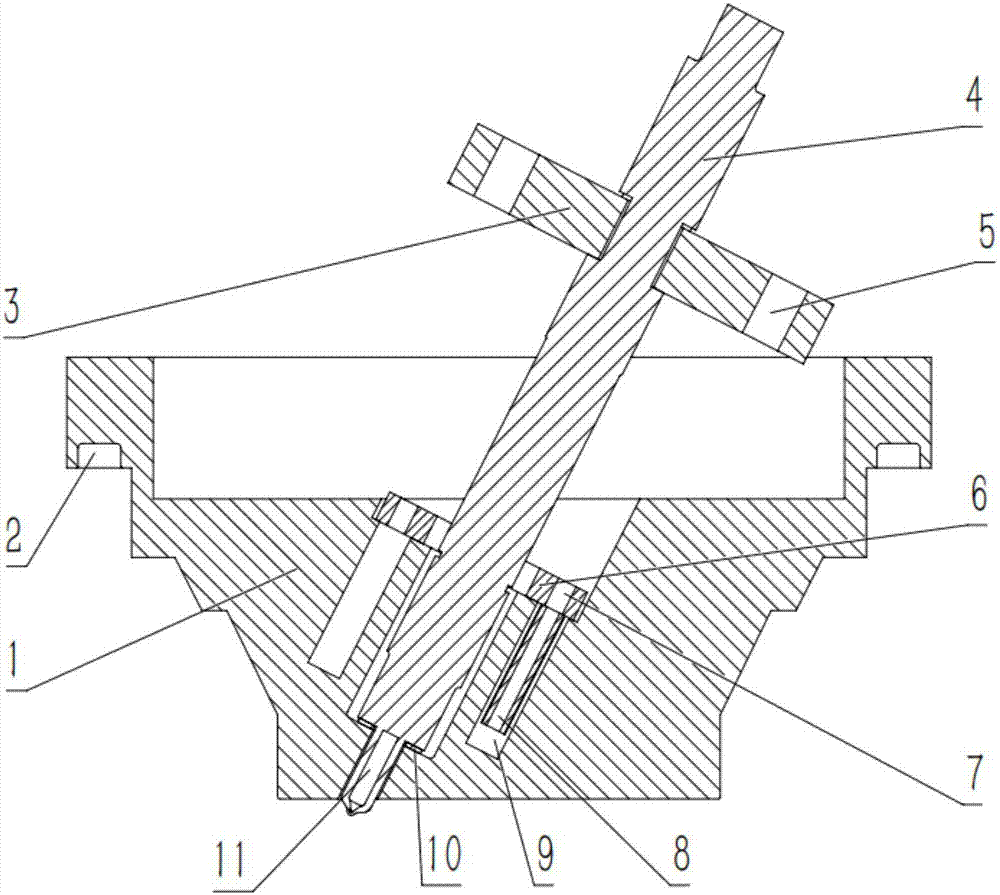

[0029] figure 1 It is the sectional view of the oblique hole fuel injector adapter device with adjustable injection direction of the present invention; as figure 1 As shown, the oblique-hole fuel injector adapter device with adjustable injection direction of the present invention includes a fuel injector adapter 1, an O-ring groove 2, an adjustable gland 3, a fuel injector 4, an arc groove 5, a cooling Water chamber cover 6, threaded hole 7, extension pipe 8, cooling water chamber 9, copper gasket 10 and fuel injection nozzle 11.

[0030] The fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com