Automatic control device for mine water pump

An automatic control and water pump technology, applied in pump control, machine/engine, liquid variable capacity machinery, etc., can solve the problems of low artificial intelligence of electric gate valves, motor burning or circuit tripping, poor starting reliability of water pumps, etc. Effectiveness of pump efficiency, elimination of pump cavitation, elimination of water hammer accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

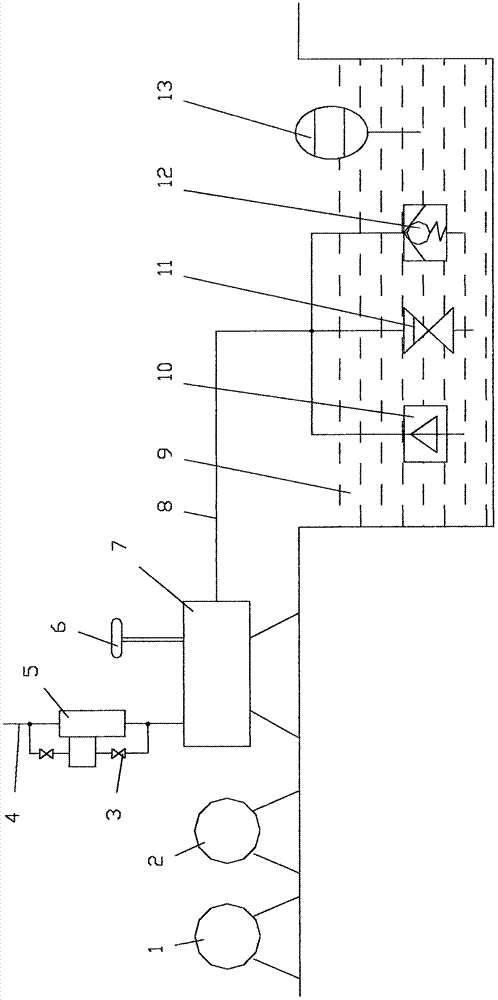

[0014] Such as figure 1 As shown, the water inlet pipe 8 of the water pump 7 is in sealing communication with the bottom valve 11 at the bottom of the water tank 9, and the water outlet pipe 4 of the water pump 7 is sealed and connected in series with the hydraulic control composite valve 5; there is a water level controller 13 in the water tank 9 , the water level controller 13 is connected to the programmable control switch 2 by signal; the water pump 7 has a deflated water full signal valve 6, and the deflated water full signal valve 6 is connected to the programmable control switch 2 by signal.

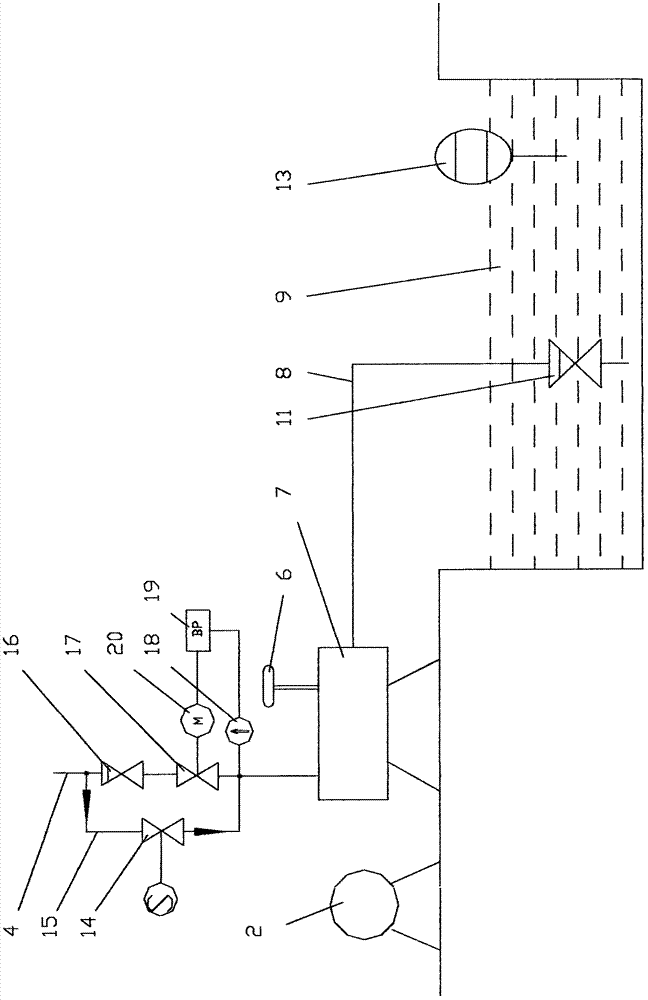

[0015] Such as figure 2 As shown, the hydraulic control composite valve 5 is replaced by a constant pressure variable frequency electric gate valve 17, and the water outlet end of the constant pressure variable frequency electric gate valve 17 is sealed and connected in series with a check valve 16, and the check valve 16 and the constant pressure variable frequency electric gate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com