Rock plug blasting method under deep water and thick sediment coverage based on modified blasting action index

A blasting action index, deep water technology, applied in blasting and other directions, to achieve the effect of sufficient theoretical basis, clear calculation steps, and reliable methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

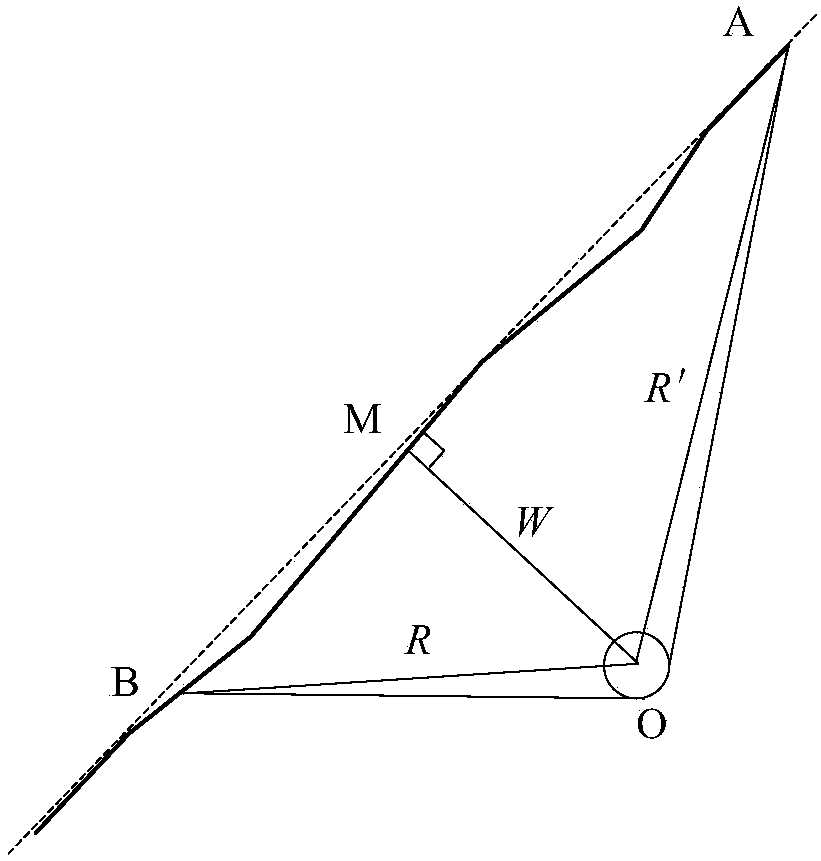

[0148] (1) Collection of information

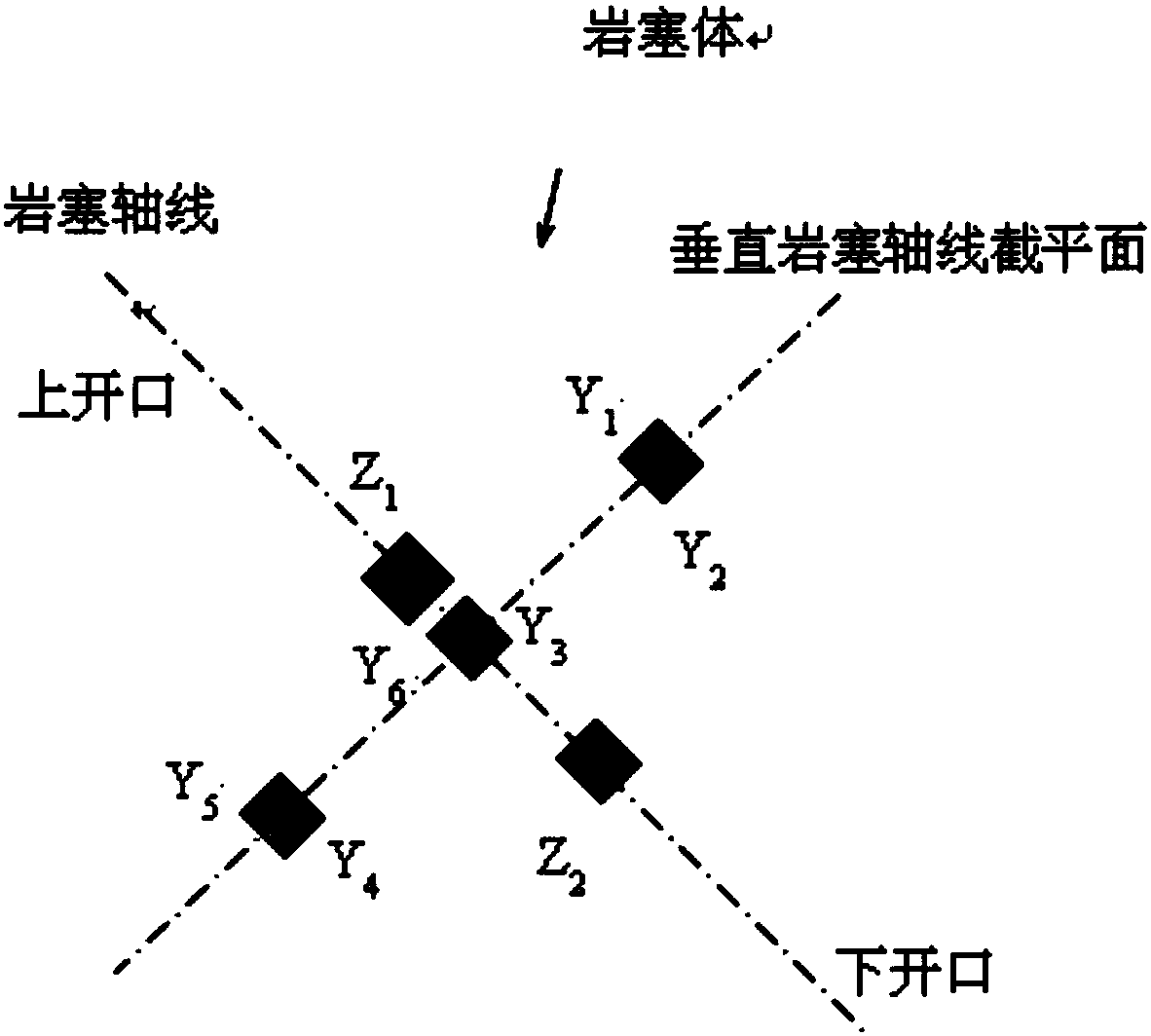

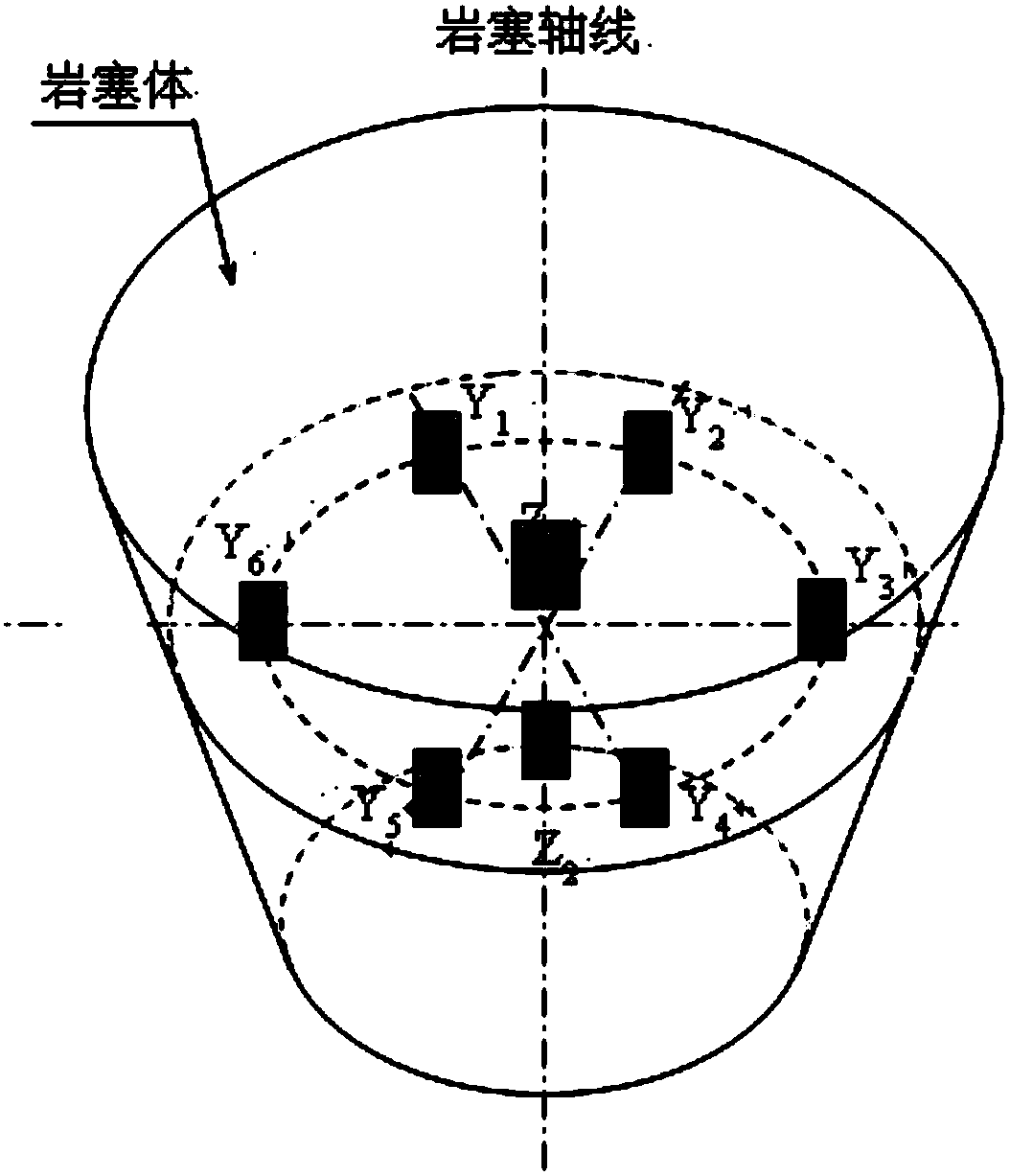

[0149] The water inlet of a certain project was constructed by underwater rock plug blasting. The designed rock plug is in the shape of an inverted truncated cone, the upper opening is approximately elliptical, the size is 21.60m×20.98m, and the diameter of the lower opening circle is 10m. The rock plug is 54.5m below the water depth, and the sediment overburden is 24.5m thick. The rock at the rock plug is mica-quartz schist, mainly weakly weathered rock, with a small amount of slightly weathered rock, the rock strength is relatively high, the average saturated compressive strength of rock is 60.MPa, and the average saturated density is 2820kg / m 3 , is a hard rock with relatively complete rocks, belonging to Type II rocks (classified according to 16 grades, which is equivalent to 10 grades). Measured from the 1:200 topographic map, the terrain slope is 40°~60°;

[0150] The rock plug blasting uses high-energy emulsion explosives and ele...

example 2

[0194] (1) Collection of information

[0195] An on-site rock plug blasting test was carried out in a certain project. According to the 1:200 geological survey results, the rock mass slope at the entrance section is steep, the rock face line along the plug mouth is uneven, the rock face line is complex, and the slope is generally 75°-85°. It is quartz mica schist and mica quartz schist, and the average saturated density of rock is 2900kg / m 3 , the rock is hard, the rock is weak to slightly weathered, the integrity of the surface rock is poor, and no weak structural planes that are not conducive to the stability of the rock plug have been found. The water depth above the plug body is 59m, and the depth of the overlying sediment layer on the rock plug body is 29m. The inner opening of the rock plug is designed to be circular, with an inner diameter of 7m and an outer opening size of 11.96×12.63m, which is approximately elliptical. The minimum thickness of the rock plug is 9.80m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com