A hydraulic design method for guide vanes of high specific speed axial flow pump

A high specific speed, hydraulic design technology, applied in the design field, can solve the problems that it is difficult to achieve the expected effect, the theoretical design and the actual model are different, so as to improve the utilization rate and hydraulic efficiency, prolong the service life and maintenance cycle, Effect of Optimizing Design Parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

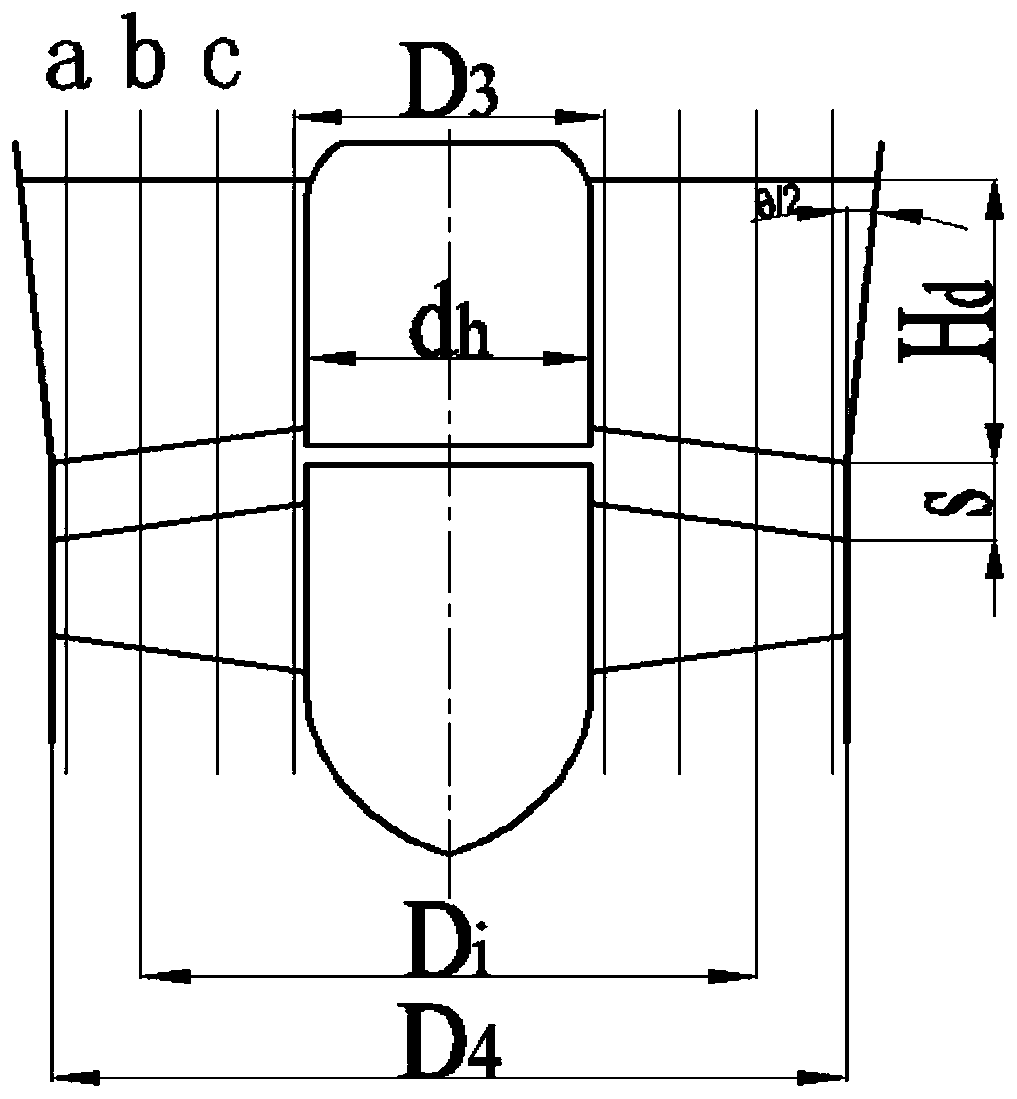

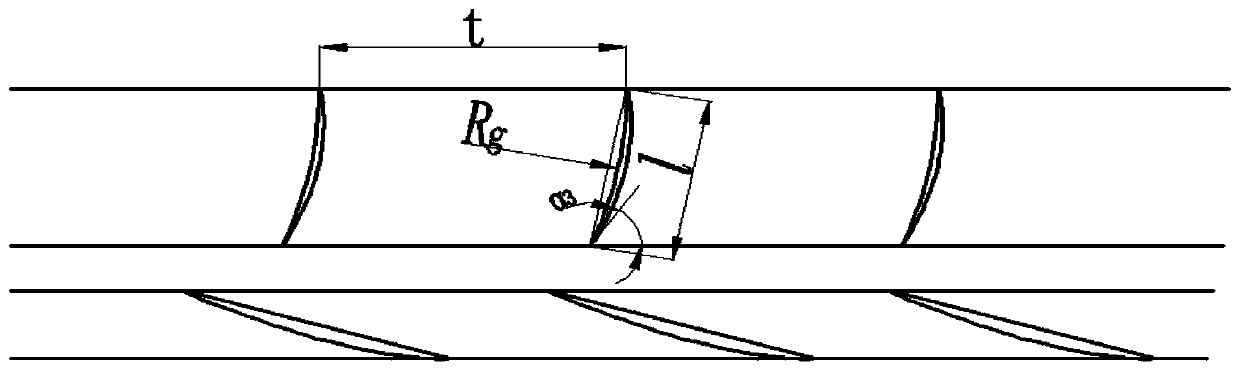

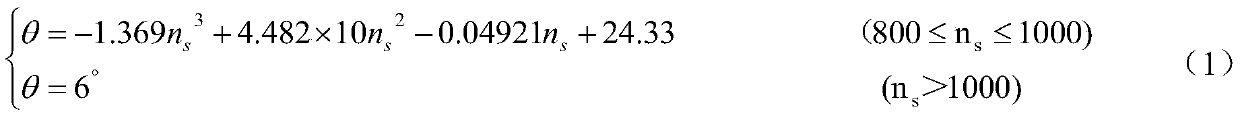

[0077] The present invention uses the following formulas to determine the diffusion angle θ including the guide vane of the axial flow pump, and the inner diameter of the guide vane inlet D 3 , Outer diameter of guide vane inlet D 4 , the distance e between the inlet edge of the guide vane and the outlet edge of the impeller, the axial height H of the guide vane hub side d , the number of guide vane blades Z g , guide vane inlet placement angle α 3 , guide vane density l / t, guide vane inlet axial surface velocity υ m3 , guide vane profile radius R g . This embodiment is in a given design condition flow Q=0.35m 3 / s, design head H=6.72m, design speed n=1450r / min, calculate guide vane hydraulic parameters:

[0078]

[0079] D. 3 =6.466n s -0.402 D. 2 (2)

[0080]

[0081]

[0082]

[0083]

[0084] (l / t) 0 =3.292×10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com