Production technology of fifth or sixth class of cable conductors and product of production technology

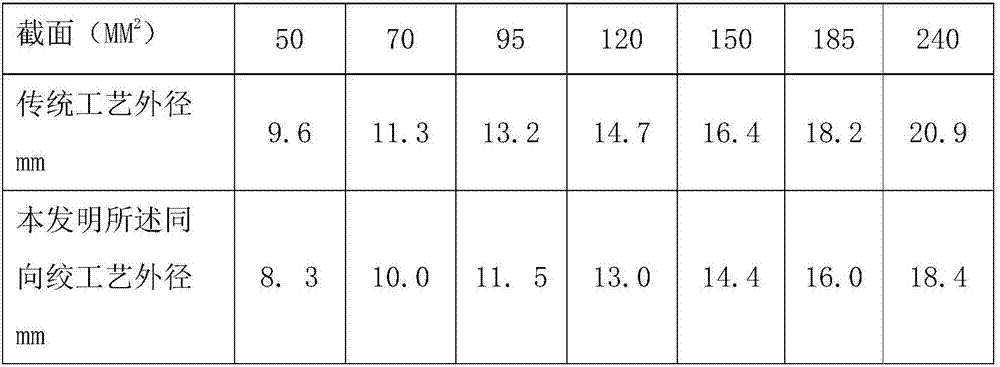

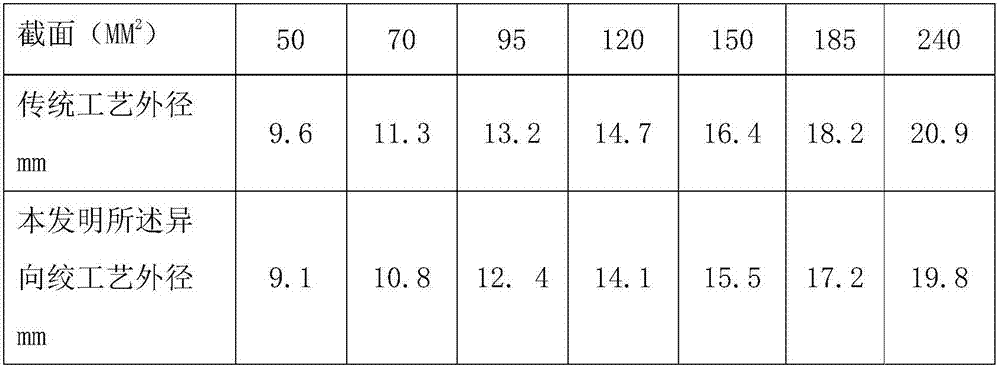

A cable conductor and production process technology, which is applied to the production process and product fields of five and six types of cable conductors, can solve the problems of low production efficiency, easy damage to conductors, waste of raw materials, etc., achieve specification saving, improve production efficiency, and save Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes.

[0028] A production process and products thereof for category five and category six cable conductors, mainly comprising the following steps:

[0029] (1) Wire harness unit: Calculate the number of monofilaments required for the cable conductor according to the cross-section of the cable conductor to be produced, and allocate the number of monofilaments contained in the wire harness unit according to the GB / T3956-2008 standard;

[0030] (2) Wire drawing: According to the GB / T3956-2008 standard and the planned section length, confirm the wire drawing length, and accurately control the length of the required beam unit through the encoder meter counting system, and use the wire drawing machine to draw the beam unit to the required length After the length is obtained, the beam unit after stretching is obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com