Para-aramid-acrylic compound pulp

A para-aramid fiber and composite pulp technology, applied in the direction of mechanical/thermomechanical pulp, paper, etc., can solve problems such as human health hazards, and achieve the effects of high efficiency in the production process, simple energy consumption, and high degree of fibrillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

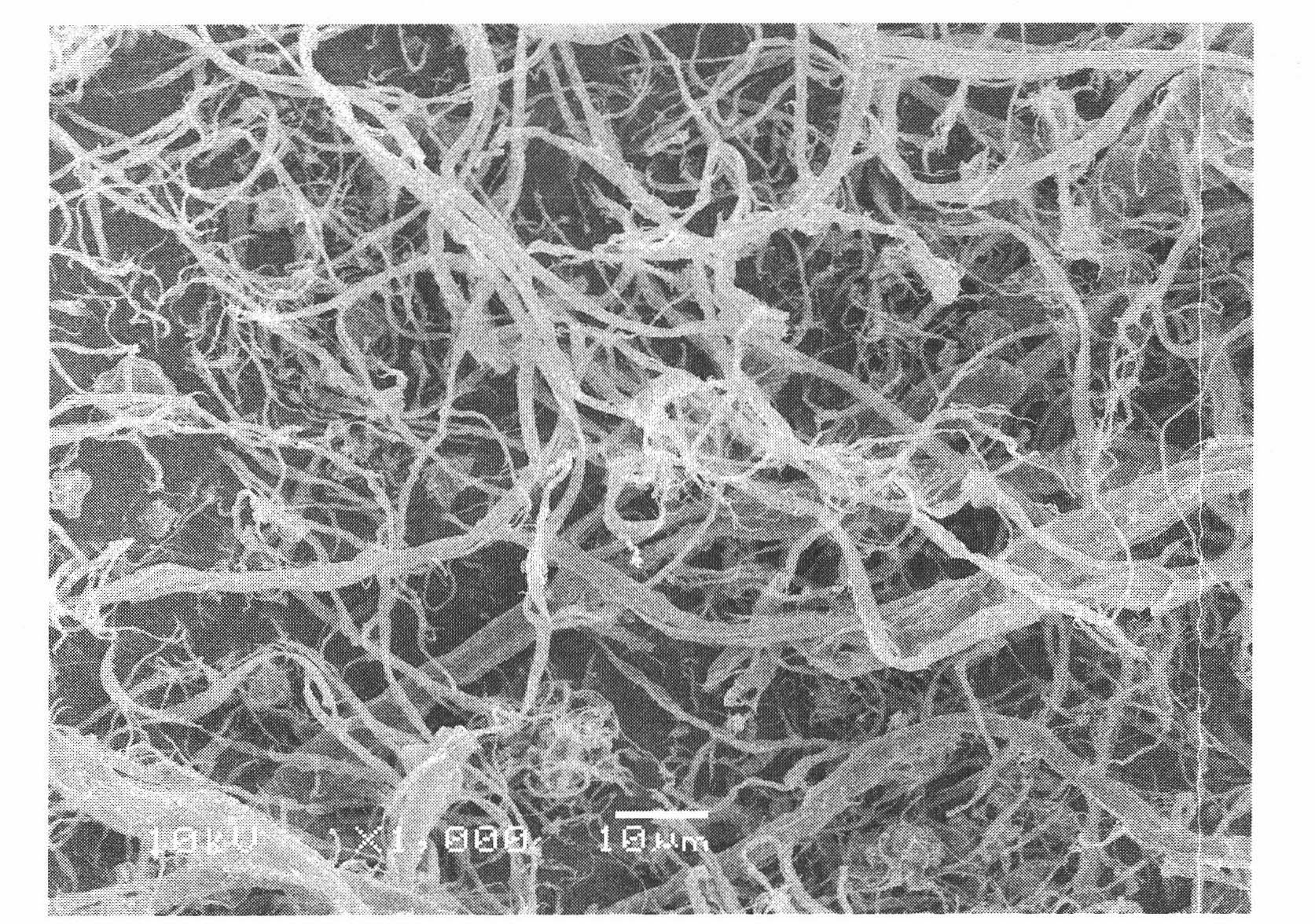

Image

Examples

example 1

[0021] Para-aramid chopped fibers with a length of 4mm and polyacrylonitrile chopped fibers with very rich internal microfibers are fed through a hollow screw volumetric feeder at a rate of 25kg / h and a flow rate of 35t / h respectively. Ionized water is fed into the disc grinder with impeller at the inlet at the same time, in 40s -1 Under the action of high shear rate, the para-aramid and polyacrylonitrile fibers are continuously mixed, dispersed and ground in the water phase, and the obtained slurry is dehydrated and dried, and the obtained para-aramid-polyacrylonitrile fiber is opened. Composite pulp fibers with a length distribution of 1.8±0.4mm and a specific surface area of 22.8m 2 / g.

example 2

[0023] Para-aramid chopped fibers with a length of 5 mm and polyacrylonitrile chopped fibers with rich internal microfibers are fed through a hollow screw volumetric feeder at a rate of 20 kg / h and a flow rate of 35 t / h, respectively. Ionized water is fed into the disc grinder with impeller at the inlet at the same time, in 40s -1 Under the action of high shear rate, the para-aramid and polyacrylonitrile fibers are continuously mixed, dispersed and ground in the water phase, and the obtained slurry is dehydrated and dried, and the obtained para-aramid-polyacrylonitrile fiber is opened. Composite pulp fibers with a length distribution of 2.0±0.4mm and a specific surface area of 17.9m 2 / g.

example 3

[0025] Para-aramid chopped fibers with a length of 3 mm and polyacrylonitrile chopped fibers with rich internal microfibers are fed through a hollow screw volumetric feeder at a rate of 30 kg / h and a flow rate of 35 t / h, respectively. Ionized water is fed into the disc grinder with impeller at the inlet at the same time, in 40s -1 Under the action of high shear rate, the para-aramid and polyacrylonitrile fibers are continuously mixed, dispersed and ground in the water phase, and the obtained slurry is dehydrated and dried, and the obtained para-aramid-polyacrylonitrile fiber is opened. Composite pulp fibers with a length distribution of 1.7±0.4mm and a specific surface area of 25.3m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com