Cooling device and method for cylindrical power battery pack

A power battery pack and cooling device technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the needs of power battery thermal management that is difficult to meet the high energy density, and it is difficult to take into account the simple and compact structure, weak air cooling capacity, etc. problem, to avoid the safety problem of the battery pack, the structure is simple, and the capillary limit is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

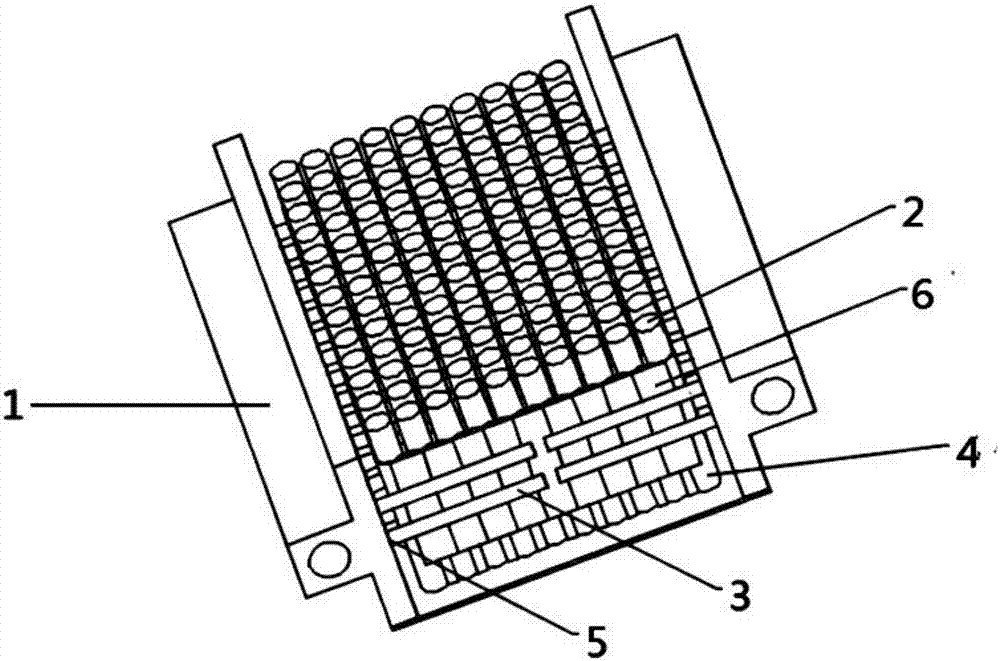

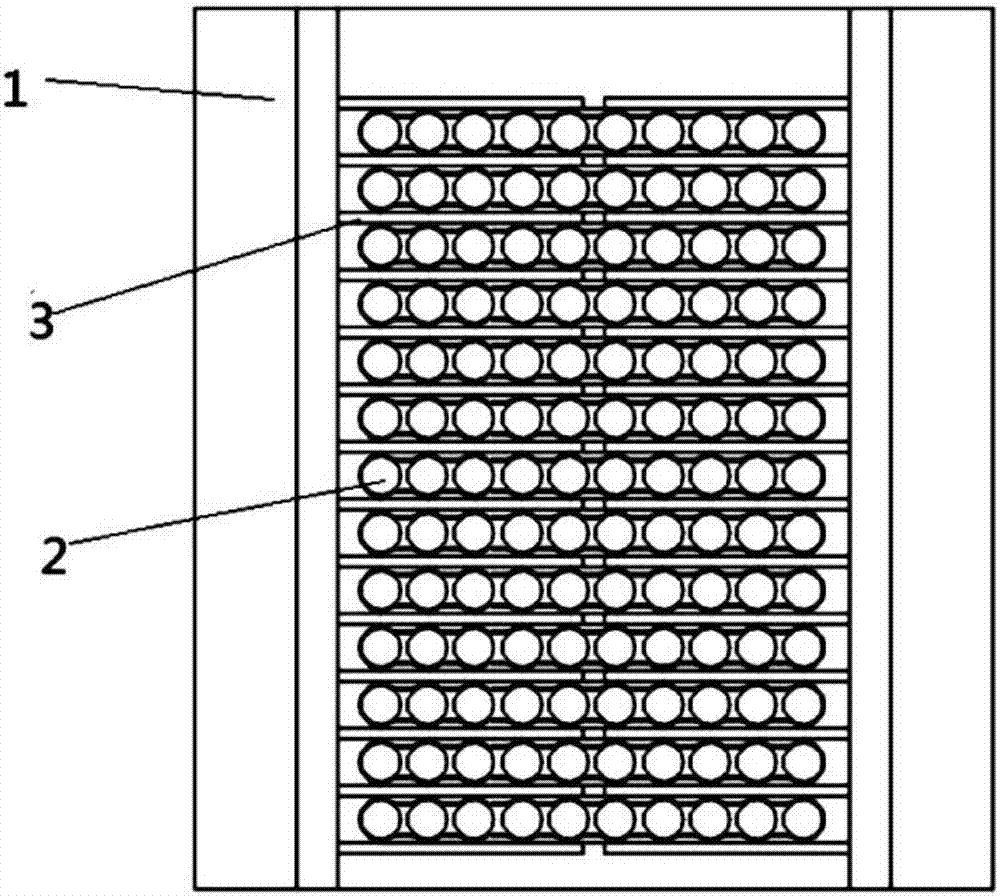

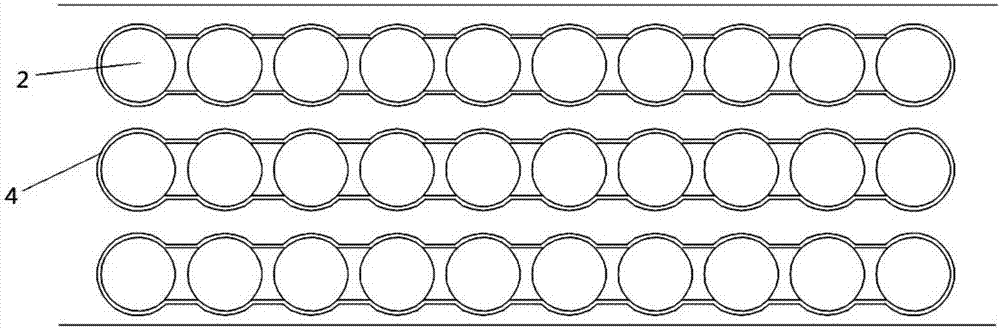

[0032] like Figures 1 to 5 shown. The invention discloses a cooling device for a cylindrical power battery pack, which includes a battery pack 2 and its cooling structure; the cooling structure includes a cooling passage 1 distributed on two sides of the battery pack 2 with a circulating cooling medium inside, and The heat generated by the battery pack 2 is transferred to the heat pipe 3 of the channel body of the cooling channel 1;

[0033] The heat generated by the battery pack 2 is indirectly transferred to the channel body of the cooling channel 1 through the heat pipe 3 , and the cooling medium circulating in the cooling channel 1 takes away the heat generated by the battery pack 2 .

[0034] The evaporating end 3-1 of the heat pipe 3 extends into the battery pack 2 and contacts the outer surface of the battery, and the condensing end 3-2 extends out of the battery pack and contacts the channel body. This structure realizes the indirect contact between the condensing e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com