Cigarette capable of highlighting aroma of first puff and manufacturing method thereof

A cigarette and aroma technology, applied in tobacco, cigar manufacturing, application, etc., can solve the problems of insufficient aroma, strong stimulation, and excessive miscellaneous gas, and achieve the effects of improving quality, reducing irritation, and reducing diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment highlights the cigarette of mouth and mouth flavor fragrance and is made in the following way:

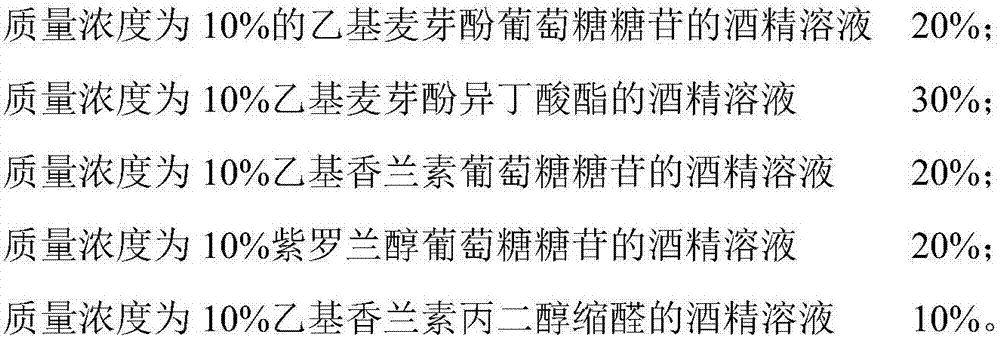

[0027] First, use the following latent fragrance spices as raw materials, and configure essence A in parts by mass:

[0028]

[0029] Then prepare the cigarette paper according to the conventional method, and prepare the cigarette paper quantitatively to be 29 g / m by adjusting the degree of beating, the flow rate of the slurry and the speed of the vehicle, etc. 2 , The air permeability is 60 Coresta.

[0030] Mix flavor A with alcohol at a mass ratio of 1:1, then add 2 mg of flavor A to each cigarette, and spray the alcohol solution of flavor A on the cigarette paper at the cutting point of the cigarette at intervals. Dry at 70°C to volatilize the alcohol to prepare flavored cigarette paper.

[0031] According to conventional methods, the leaves, flavors and fragrances, filters, etc. of cigarettes are prepared, and the cigarette product A with pro...

Embodiment 2

[0033] The present embodiment highlights the cigarette of mouth and mouth flavor fragrance and is made in the following way:

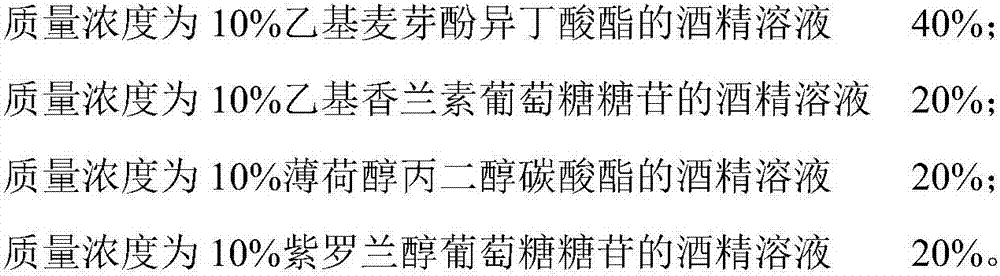

[0034] First, use the following latent fragrance spices as raw materials, and configure essence B in parts by mass:

[0035]

[0036] The essence B is mixed with the steel stamp ink of the cigarette printing stamp mark according to a certain ratio, and after adjusting to a suitable viscosity, it is added into the cigarette steel stamp ink tank. According to the conventional cigarette production and steel stamp printing steps, the steel stamp with flavoring B added is positioned and printed at the end of the cut cigarette, and after printing and coiling, the cigarette product B with the flavored steel stamp logo on the end is prepared. The added amount of essence B after conversion accounts for 1 / 10,000 of the weight of shredded tobacco.

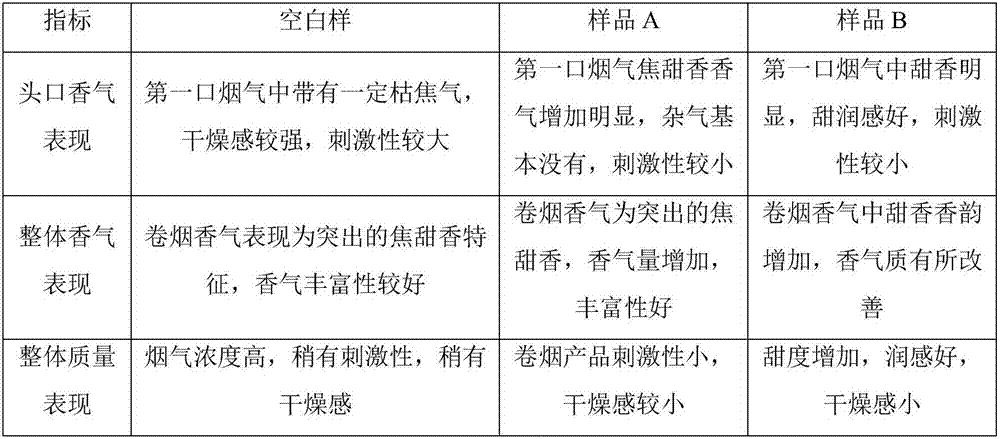

[0037] The evaluation result of above-mentioned embodiment gained product is shown in Table 1:

[0038] Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com