A wear repair system for the sealing position of the drive shell of the shield machine

A drive shell and wear repair technology, which is applied in the field of parts repair, can solve problems such as wear and tear of the seal position of the drive shell, reduction of the structural strength and bearing capacity of the parts, and damage to the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

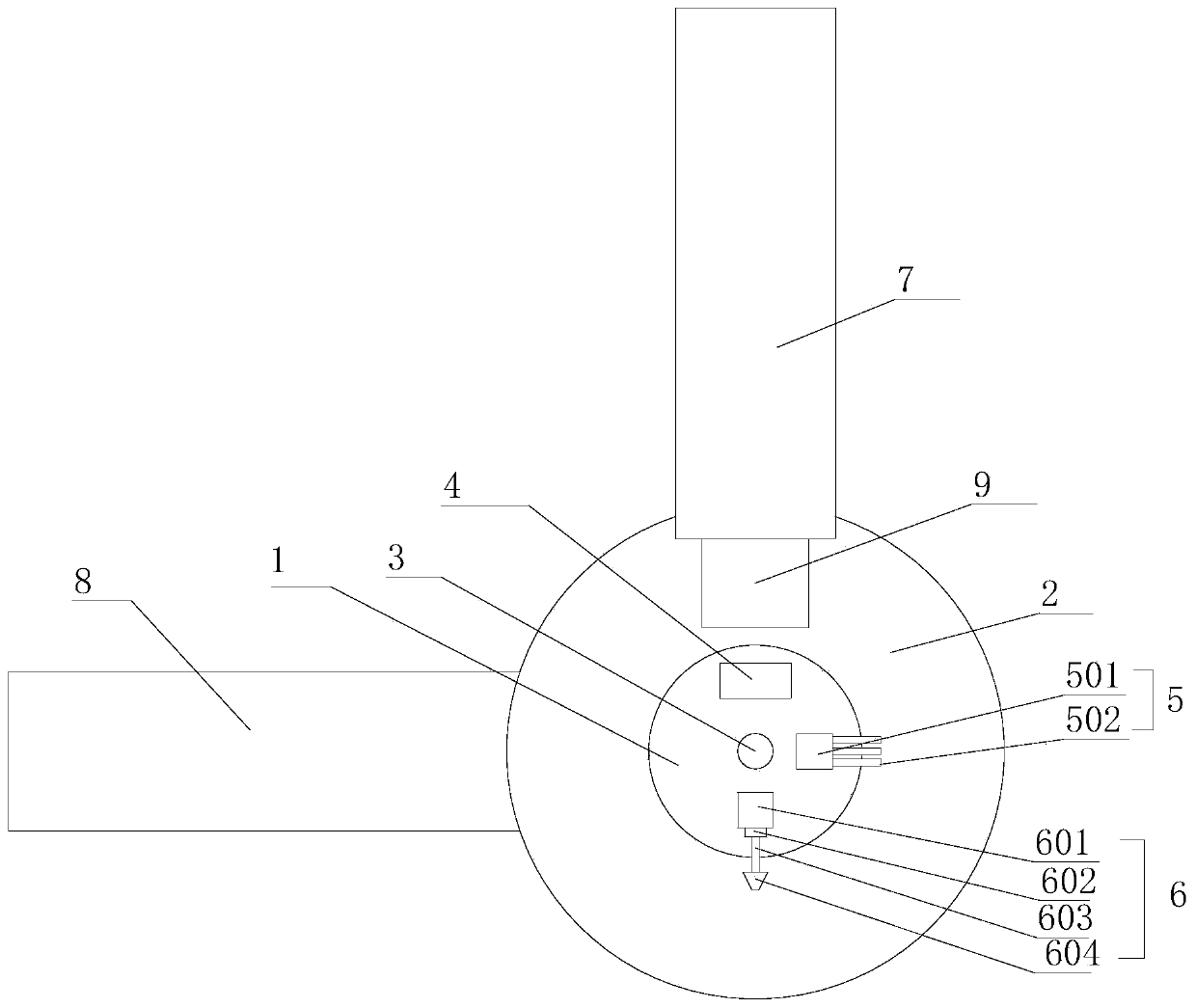

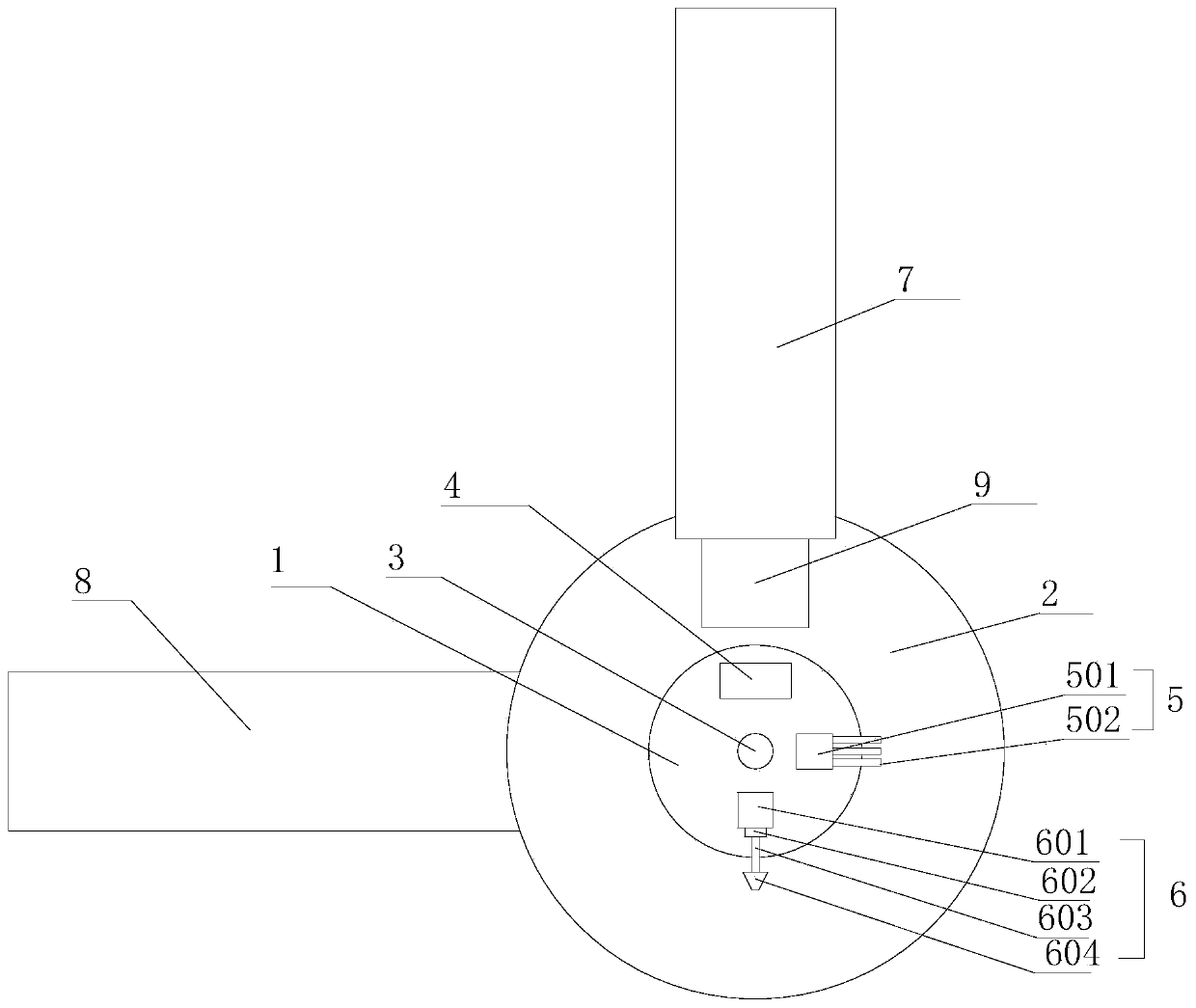

[0010] refer to figure 1 , the present invention proposes a wear repair system for the seal position of the drive casing of the shield machine, including a fixed disk 1, a rotary disk 2, a rotating shaft 3, a driving device, a detection device 4, a welding repair device 5, a grinding device 6, a first conveying device 7, The second conveying device 8 and the control device, wherein:

[0011] The turntable 2 is rotationally connected with the fixed disk 1 through the rotating shaft 3, the central axis of the turntable 2 coincides with the central axis of the fixed disk 1 and the diameter of the turntable 2 is larger than the diameter of the fixed disk 1, the driving device is connected with the rotating shaft 3 and drives the rotating shaft 3 to rotate, and the turntable 2 is provided with a blanking area, and a dodge door 9 is provided in the blanking area.

[0012] The detection device 4, the welding repair device 5, and the grinding device 6 are sequentially installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com