Forward wheel drive dual-mode hybrid power transmission device

A hybrid power and transmission technology, which is applied in the arrangement of multiple different prime movers of power plants, pneumatic power plants, and general power plants, can solve problems such as large axial dimensions, reduce torque requirements, and reduce transmission costs. High efficiency, reducing the effect of primary energy conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

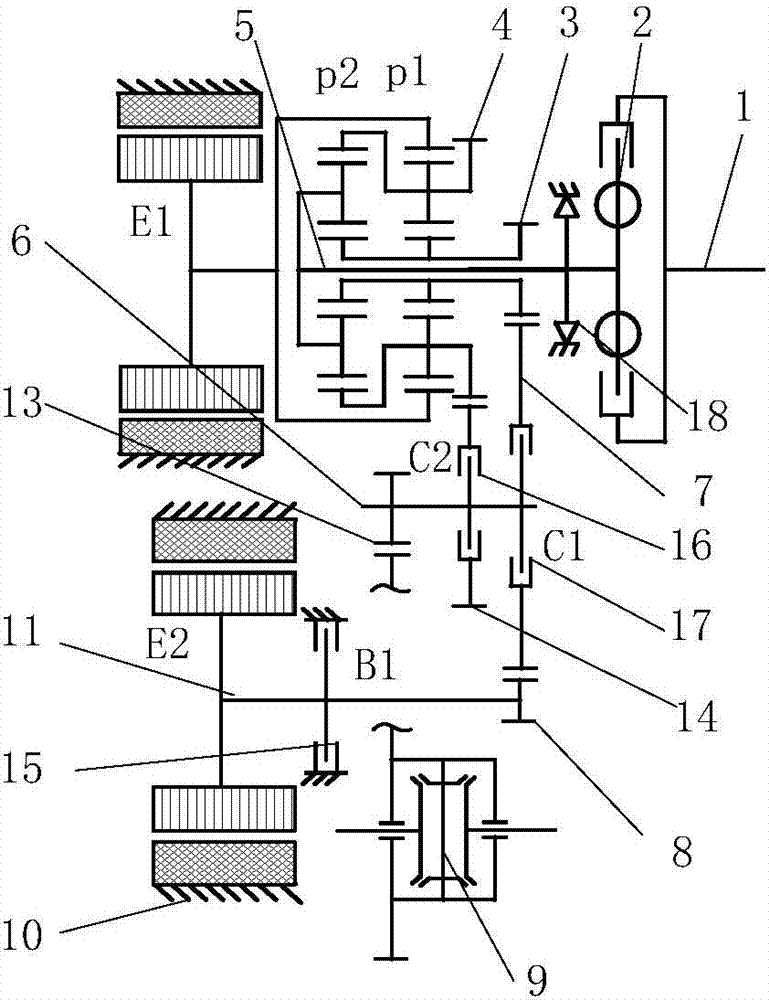

Embodiment 1

[0018] Example 1: See attached figure 1 , A dual-mode hybrid power transmission device for a front-drive vehicle, which includes: engine input shaft 1, torsion damper 2, first gear 3, power split planetary mechanism, planetary mechanism output gear 4, input shaft 5, output shaft 6 , The second gear 7, the third gear 8, the differential 9, the housing 10, the first motor E1, the second motor E2, the second motor shaft 11, the output gear 13, the fourth gear 14, the brake 15, the first Clutch 16, second clutch 17, one-way clutch 18;

[0019] The power from the engine is transmitted to the input shaft 5 through the input shaft 1 and the torque damper 2. The input shaft 5 is provided with a one-way clutch 18, wherein the one-way clutch 18 is used to prevent the engine from reversing;

[0020] The power split planetary mechanism includes: planetary row P1 and planetary row P2; planetary row P1 sun gear, planetary row P2 sun gear and first gear 3 fixed connection, planetary row P1 planet...

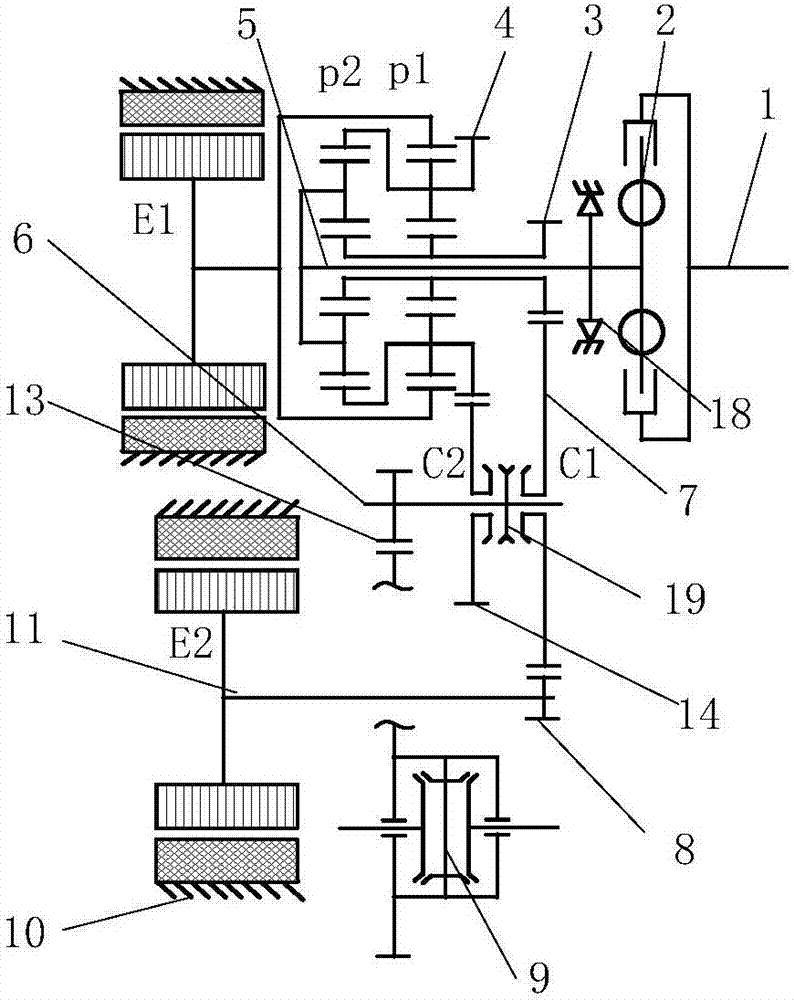

Embodiment 2

[0038] Example 2: See attached figure 2 , A dual-mode hybrid power transmission device for a front-drive vehicle, which includes the engine input shaft 1, torsion damper 2, first gear 3, power split planetary mechanism, planetary mechanism output gear 4, input Shaft 5, output shaft 6, second gear 7, third gear 8, differential 9, housing 10, first motor E1, second motor E2, second motor shaft 11, output gear 13, fourth gear 14 , The one-way clutch 18, the synchronizer 19, and the connection structure of these components; Compared with the first embodiment, this embodiment cancels the brake 15, and the second clutch 17 and the first clutch 16 are replaced by the synchronizer 19;

[0039] The left end of the synchronizer 19 is connected with the fourth gear 14 and the right end is connected with the second gear 7; when the synchronizer 19 is right-engaged, the second gear 7 is fixedly connected to the output shaft 6, and the power transmission device is in a rectangular splitter Po...

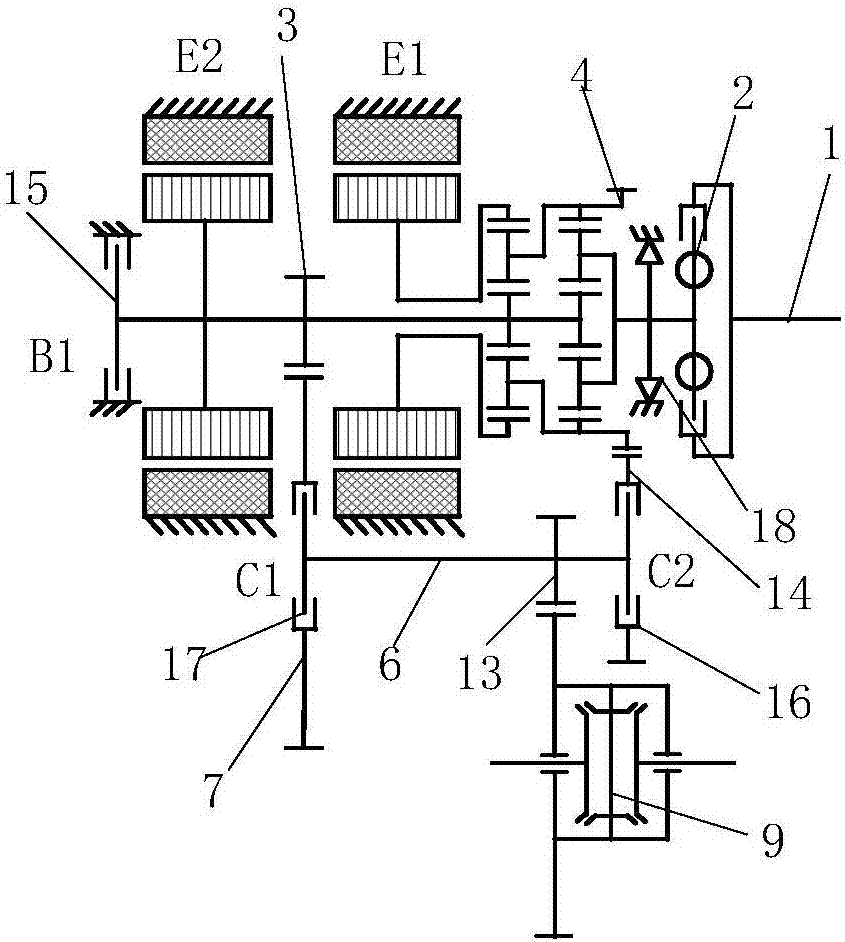

Embodiment 3

[0044] Example 3: See attached image 3 , A dual-mode hybrid power transmission device for a front-drive vehicle, which includes the engine input shaft 1, the torsion damper 2, the first gear 3, the power split planetary mechanism, the planetary mechanism output gear 4, the output Shaft 6, second gear 7, differential 9, housing 10, first motor E1, second motor E2, output gear 13, fourth gear 14, one-way clutch 18, brake 15, clutch 16, clutch 17, And the connection structure of these components; Compared with embodiment 1, in this embodiment, the first motor E1 and the second motor E2 are coaxially arranged;

[0045] The following table is the operation logic of this embodiment:

[0046]

[0047] In the above: C1 refers to the second clutch 17 is engaged, C2 refers to the first clutch 16, B1 refers to the brake 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com