Automatic paving device for brick on ground

A brick laying device and automatic technology, applied in roads, road repairs, roads, etc., can solve problems such as low work efficiency, expensive labor, and high technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is realized through the following technical solutions:

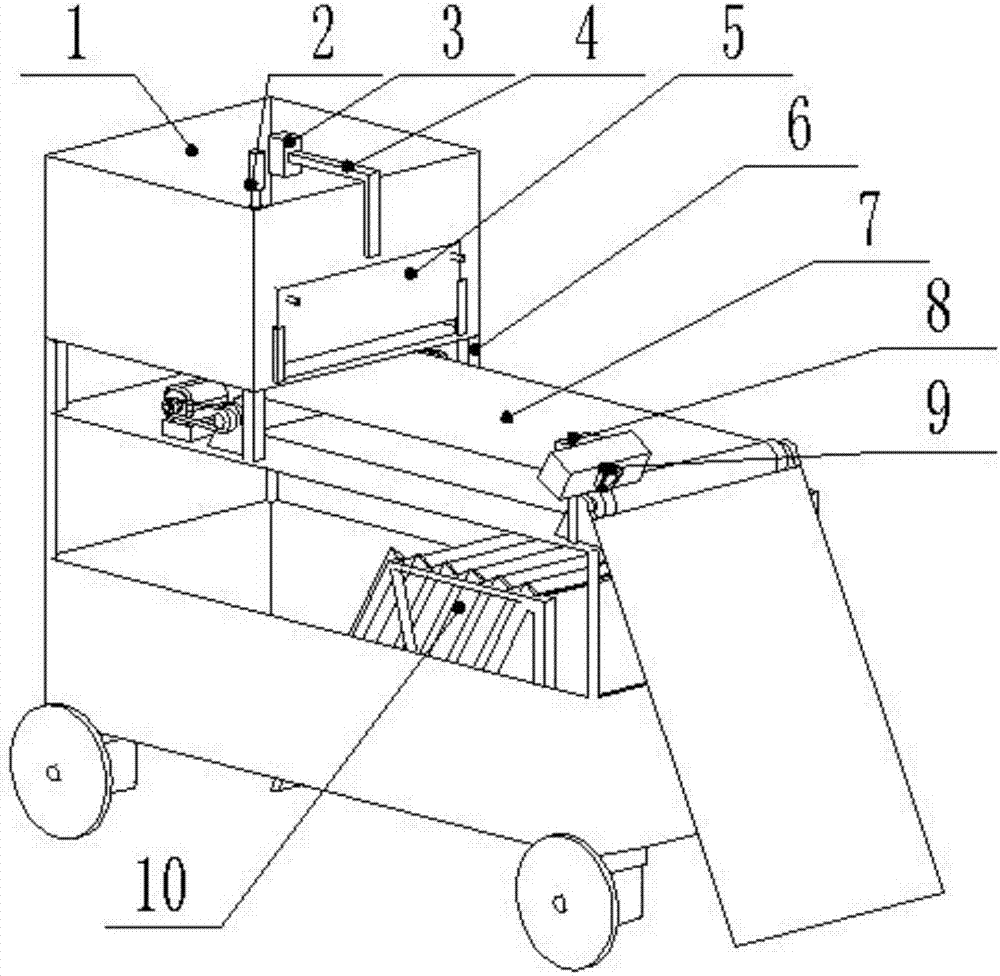

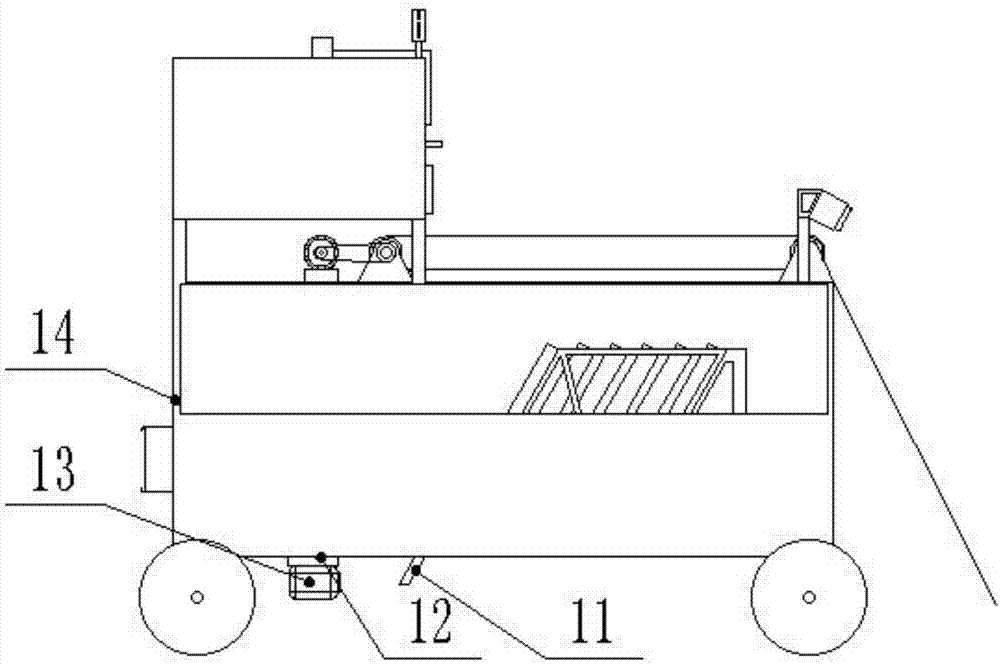

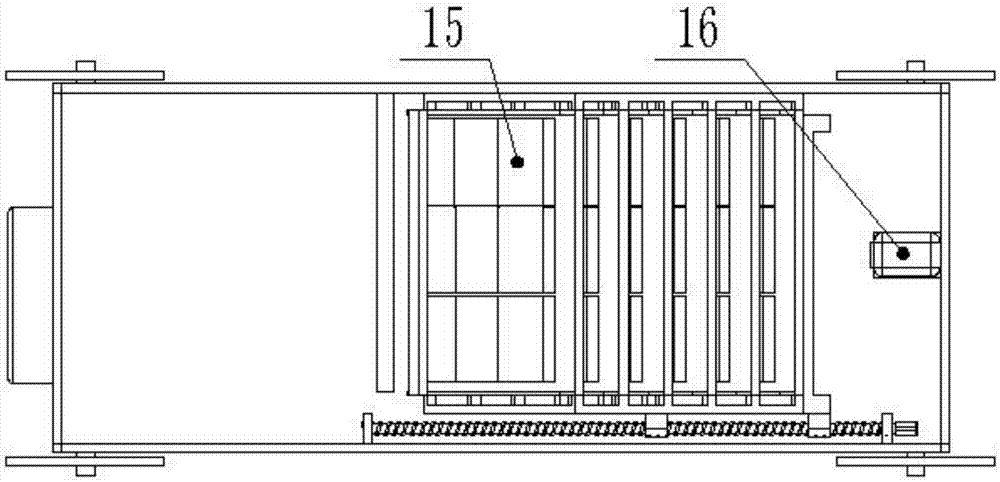

[0021] A ground automatic brick laying device, comprising an upper compartment 1, an alarm 2, an ultrasonic sensor 3, an ultrasonic sensor base 4, a silt baffle 5, a first bracket 6, a transmission device 7, a camera base 8, a camera 9, Brick laying device 10, brick output pallet 11, photoelectric sensor base 12, photoelectric sensor 13, second support 14, bricks 15, second ultrasonic sensor 16, first motor base 17, first motor 18, wheels 19 , controller 20, alarm base 21, transmission power unit 22, lower compartment 23 and slide plate 24, described upper compartment 1 is installed on the first support 6, and described alarm 2 is installed on the alarm base 21, The ultrasonic sensor 3 is fixed on the ultrasonic sensor base 4, the ultrasonic sensor base 4 is installed on the upper compartment 1, and the mud baffle 5 is installed on the upper compartment 1, and its position is located in front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com