Incinerator dynamic turbulent flow rotational flow device and working method thereof

A swirling device and incinerator technology, which is applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems that the emission cannot be continuously and stably met, the garbage cannot be completely burned, and the oxygen supply is insufficient, and the structure is simple, the design is reasonable, The effect of curbing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

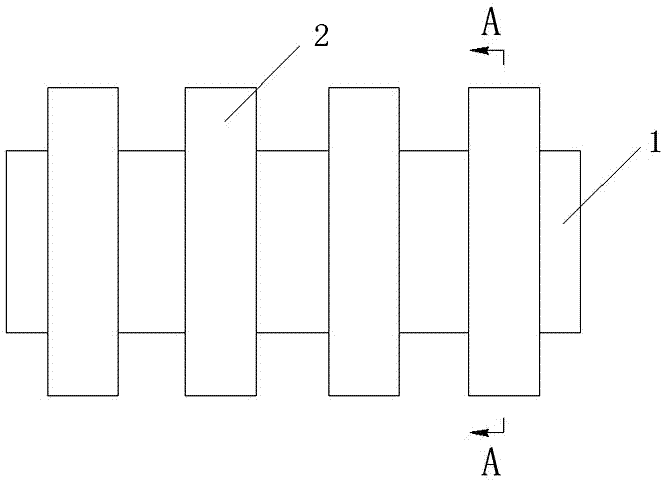

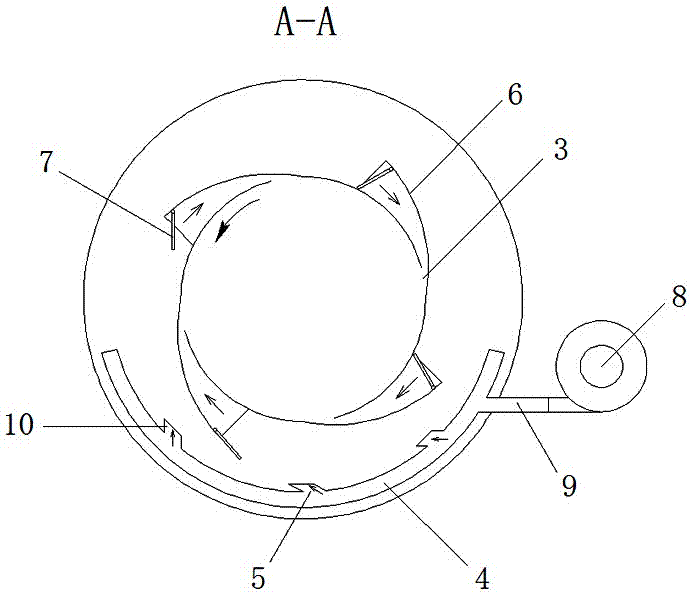

[0014] Such as Figure 1~2 As shown, a dynamic turbulent swirling device for an incinerator includes a self-rotating incinerator 1, and a plurality of annular shells 2 arranged in the axial direction are set on the periphery of the incinerator, and the incinerator furnace where the annular shell 2 is located A plurality of air inlets 3 are arranged at intervals around the body, and an arc-shaped air distribution pipe 4 located below the incinerator 1 is arranged inside the annular casing 2. A plurality of air outlets 5 are arranged at intervals on the upper side of the air distribution pipe 4. Inside the annular casing Each air inlet 3 is provided with a horn-shaped air inlet guide shell 6, the small end of the air inlet guide shell 6 is connected to the air inlet 3, and the air inlet direction of the air inlet guide shell 6 is opposite to the rotation direction of the incinerator 1. The air distribution pipe blows air into the annular shell 2 and blows oxygen into the inciner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com