Sorting detection process and equipment used for QFN-BGA semiconductor chips

A technology of QFN-BGA and testing equipment, which is applied in semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, conveyor objects, etc. It can solve the problems of production efficiency to be improved and low degree of automation, and achieve strong functionality , high degree of automation and high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the drawings.

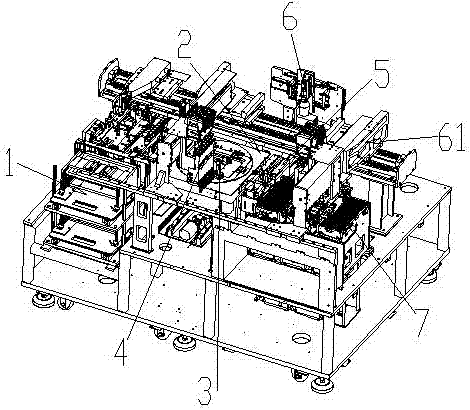

[0037] Such as figure 1 As shown, the sorting and testing equipment for QFN-BGA semiconductor chips includes a loading module 1, a workbench module 2, a thimble module 3, a suction head module 4, an array stage module 5, and a vision module 6 and receiving module 7, the material box containing the blanks is loaded on the feeding module, and the blanks are transferred between the feeding module and the workbench module through the material transfer module 61, and the ejector module The suction head module realizes the transfer, peeling and detection of the material between the workbench module and the vision module. The suction head module realizes the transfer and sorting of the chip between the vision module and the receiving module.

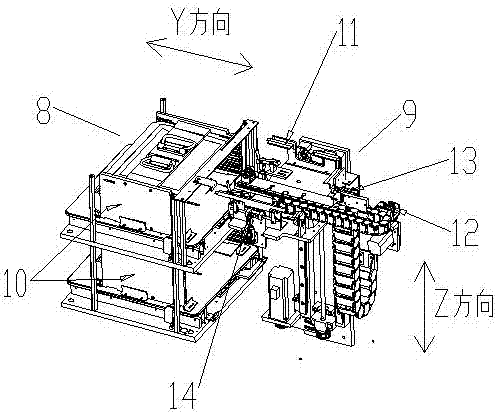

[0038] Specific, such as figure 2 As shown, the loading module may include a loading platform 8 and a material elevator 9. The loading platform include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com