Solar battery piece conveying mechanism

A technology of solar cells and transmission mechanisms, applied to conveyor objects, circuits, photovoltaic power generation, etc., can solve problems such as high cost, poor stability, and complex structure of transmission mechanisms, and achieve low cost, small lifting distance, and transmission speed high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

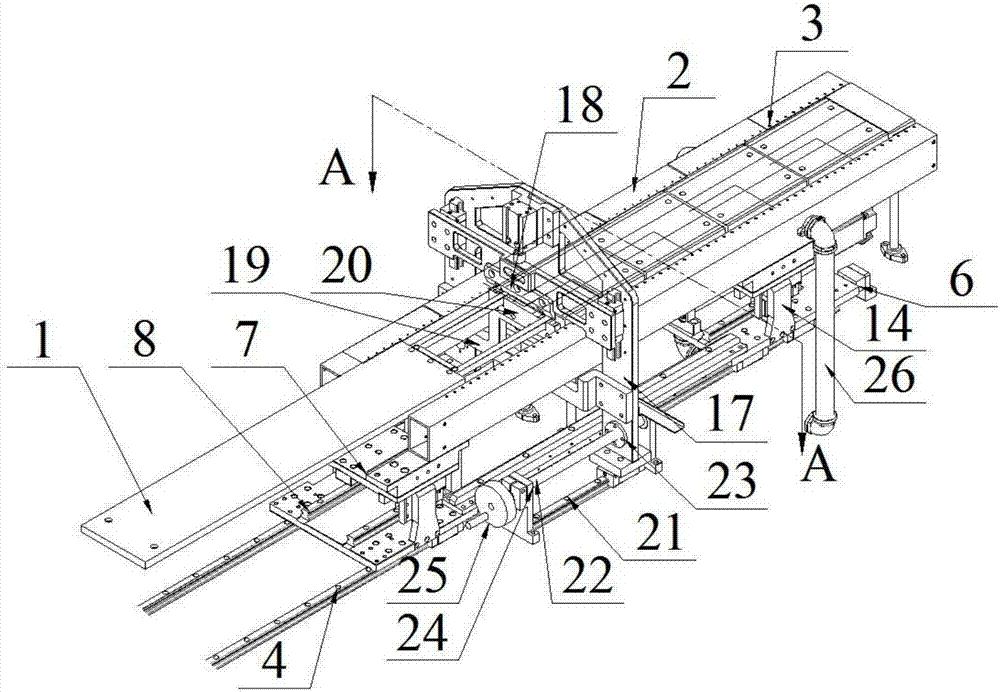

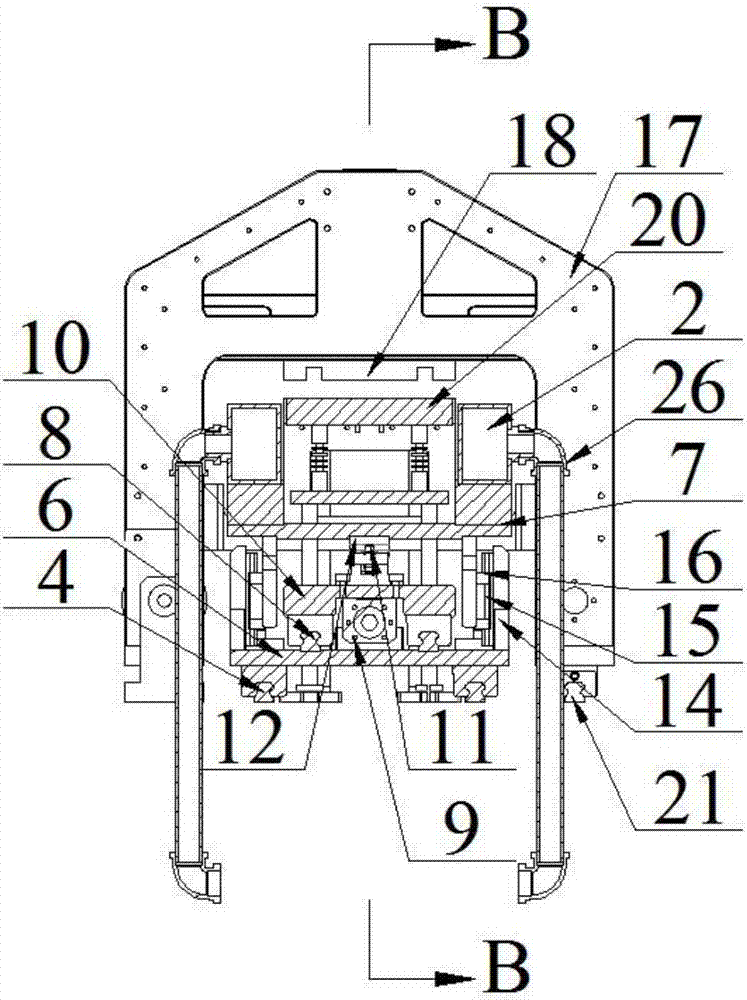

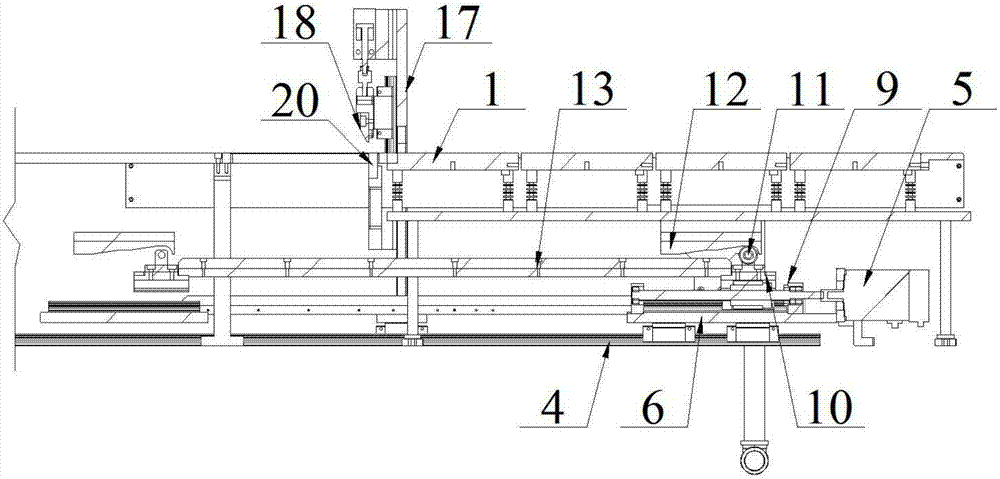

[0034] Such as Figure 1~3 As shown, a solar battery sheet transmission mechanism includes a stationary platform 1 and a movable platform. The stationary platform 1 is a flat plate structure arranged along the horizontal and longitudinal directions. The stationary platform 1 is a fixed structure that does not move during use. Support the cell when cutting the ribbon.

[0035] The activity platform of this embodiment is as Figure 1~3As shown, the movable platform includes two adsorption tubes 2 that are arranged on both lateral sides of the stationary platform 1. The adsorption tube 2 is a square pipe with a plurality of adsorption holes 3 arranged on its upper end surface along the horizontal and vertical directions. Connect the vacuum pipeline 26, one end of the vacuum pipeline 26 is communicated with the adsorption tube 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com