Box culvert type large-scale sea water intake structure, construction structure and construction method

A technology for structures and sea water, applied to drainage structures, buildings, waterway systems, etc., can solve the problems of large underwater engineering volume, unsuitable for large-scale water intake projects, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

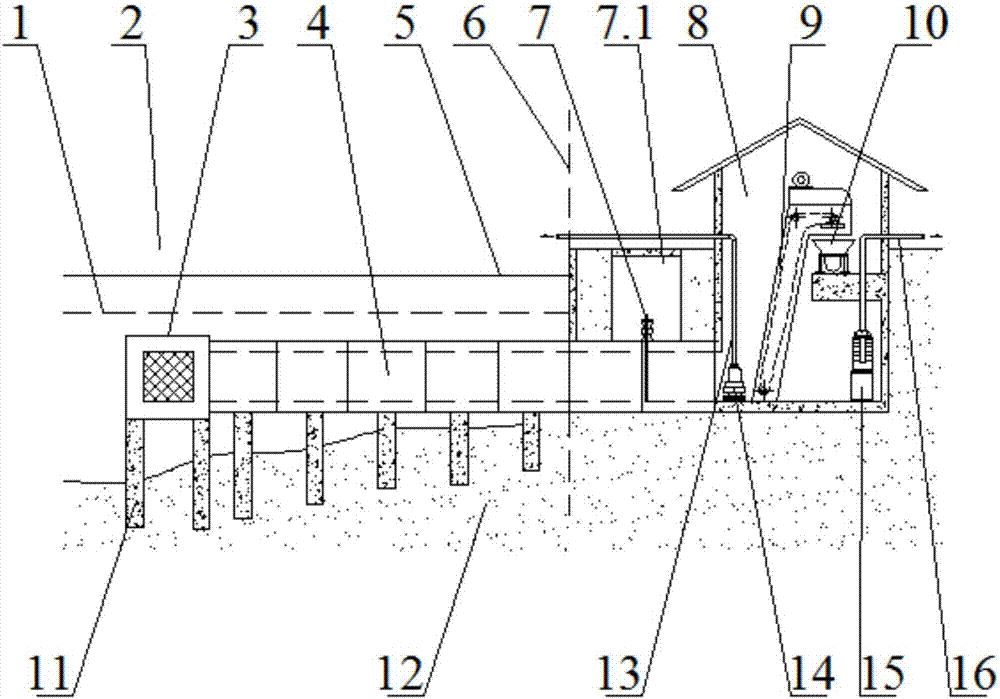

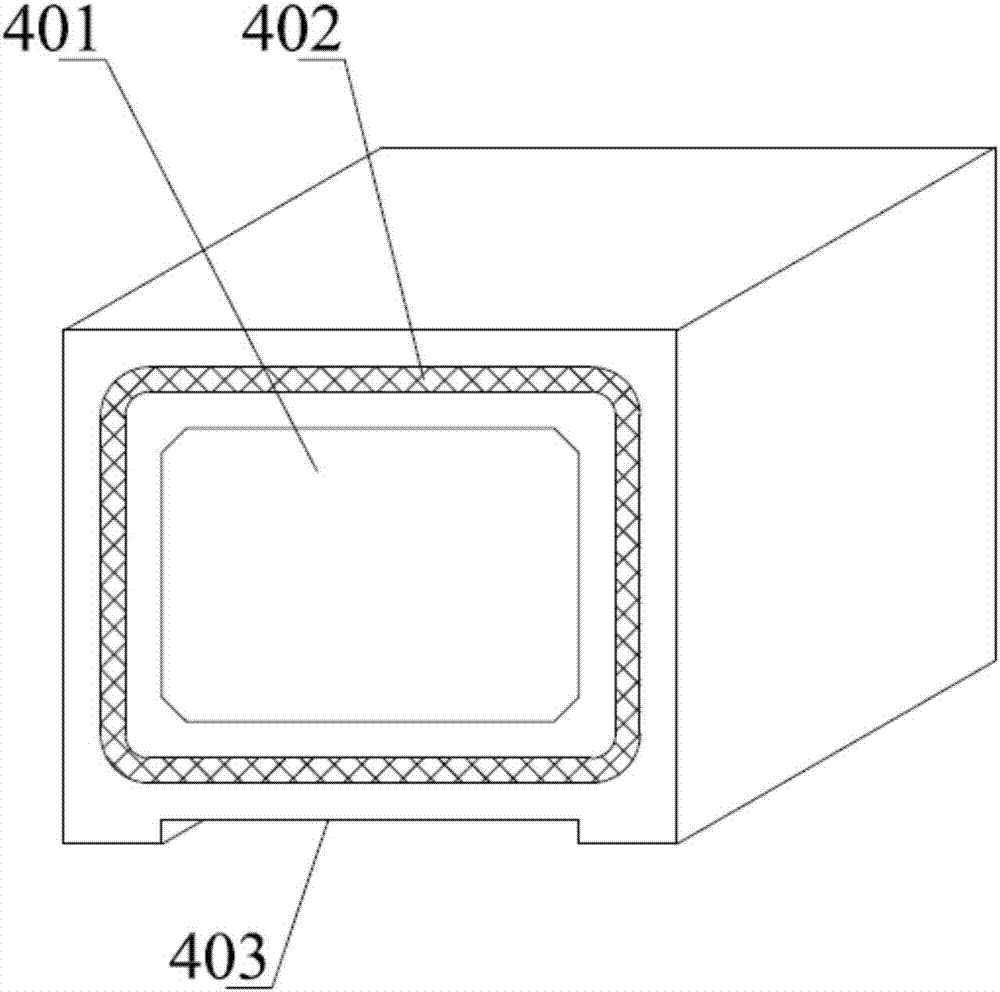

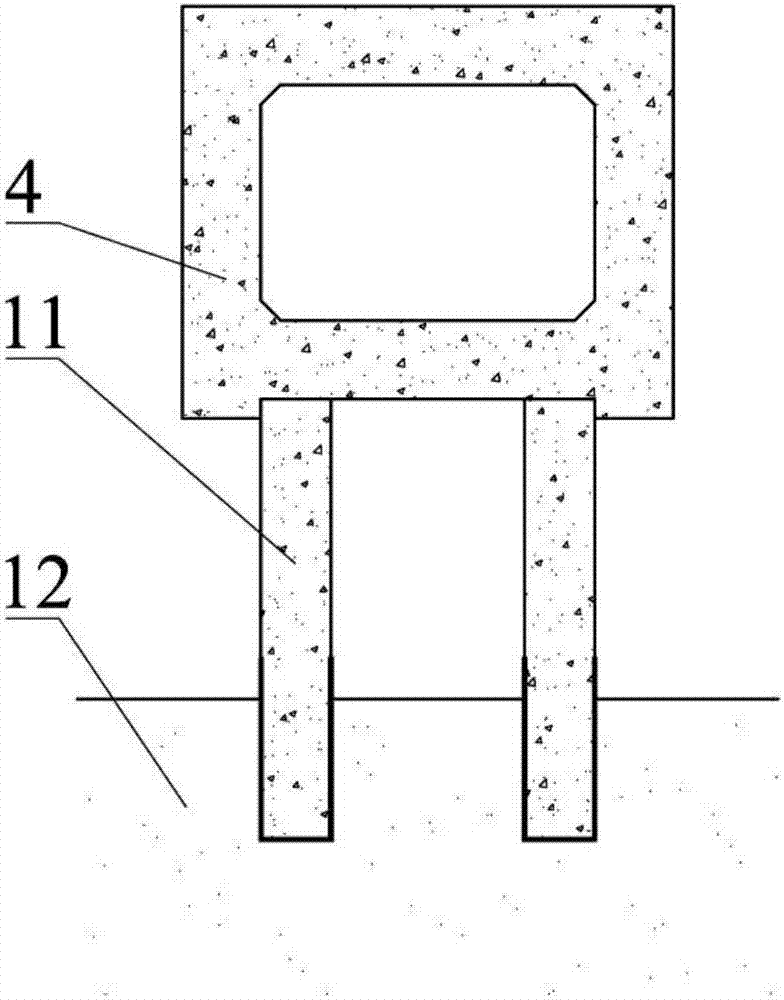

[0042]A box culvert type large-scale seawater intake structure, comprising a water intake box culvert 4, a seawater intake 3 is arranged at one end of the water intake box culvert 4 facing the sea, the other end of the water intake box culvert 4 is connected to a pump room 8, and piles are arranged below the water intake box culvert 4 The base 11 is used to support the water intake box culvert 4; the water intake box culvert 4 is multi-section, and the gate valve 7 and the gate valve well 7.1 are set between the first section of the water intake box culvert and the second section of the water intake box culvert adjacent to the pump house 8; Set up a sewage pump 14 near the side of the water intake box culvert 4, and set a water intake pump 15 in the pump room 8 away from the side of the water intake box culvert. The pipe 13 and the water intake pump 15 are connected to the water intake pipe 16. A rolling grill 9 is arranged between the sewage pump 14 and the water intake pump 1...

Embodiment 2

[0047] A construction structure of a box culvert type large-scale sea water intake structure, including a cofferdam 6, a pump house 8 is arranged in the cofferdam 6, and the side of the pump house 8 facing the sea is connected to the first section of the water intake box culvert, and the first section of the water intake box culvert faces A gate valve 7 is set on one side of the sea; a sewage pump 14 is set on the side close to the water intake box culvert in the pump room 8, and a water intake pump 15 is set on the side far away from the water intake box culvert in the pump room 8, and both the sewage pump 14 and the water intake pump 15 are set in In the lower part of the pump room 8, the sewage pump 14 is connected to the sewage pipe 13, and the water intake pump 15 is connected to the water intake pipe 16. A rolling grill 9 is arranged between the sewage pump 14 and the water intake pump 15, and the lower end of the rolling grill 9 extends to At the bottom of the pump room ...

Embodiment 3

[0051] A construction method for a box-culvert large-scale seawater intake structure comprises the following steps in sequence:

[0052] (1) Set up the cofferdam 6 near the land, drain the seawater in the cofferdam 6, remove the seabed silt, excavate the earthwork on the coast, backfill and compact it in layers;

[0053] (2) Build the foundation of the pump house in the cofferdam 6, build the pump house 8 on the foundation of the pump house, and assume the first section of the water intake box culvert on the side of the pump room 8 facing the sea, and the first section of the water intake box culvert A gate valve 7 is arranged on the side facing the sea;

[0054] (3) Close the gate valve 7 and remove the cofferdam 6;

[0055] (4) Drive steel pipe piles on the seabed 12, level the support surface by cutting, pour concrete after leveling, and complete the pile foundation 6;

[0056] (5) Set up the water intake box culvert 4 to the pile foundation 6 in sequence, and set the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com