Power transmission line live work robot and its online and offline control method

A technology for live work and transmission lines, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of difficult access of aerial ladder vehicles, high degree of danger, high labor intensity, etc., and achieve the effect of improving efficiency, high degree of automation, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

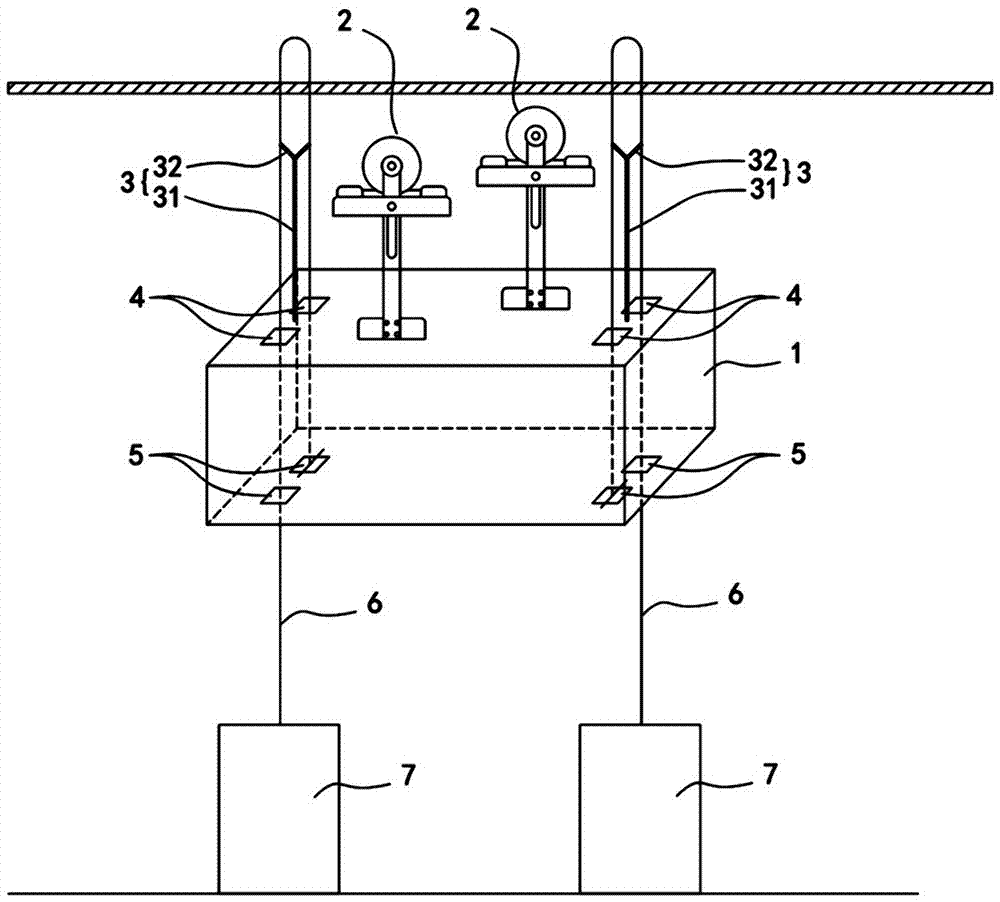

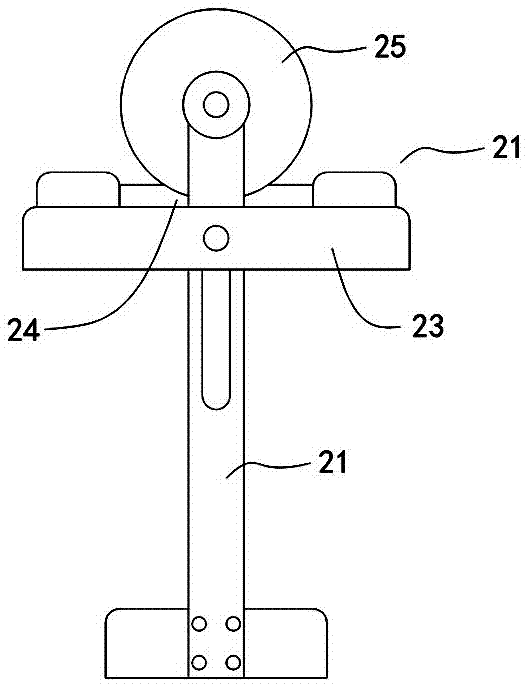

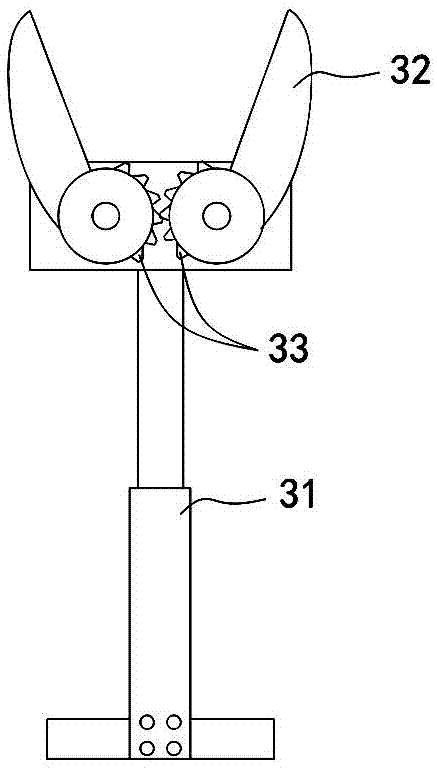

[0032] Such as figure 1 As shown, the transmission line live working robot of this embodiment includes a box body 1 and a control unit located in the box body 1, a pair of wire walking wheels 2 are provided on the top of the box body 1, and support wires are provided on both sides of the box body 1. device 3, and the upper surface of the box body 1 is provided with upper perforations 4 on both sides of the wire support device 3, and the lower surface of the box body 1 is provided with lower perforations 5 corresponding to the upper perforations 4 along the vertical direction. Both sides of the body 1 are provided with insulating ropes 6, and the two ends of the insulating ropes 6 respectively pass through an upper perforation 4 on the same side of the box body 1 and a lower perforation 5 on the lower side of the box body 1, and then protrude, and one end of the insulating rope 6 is clamped. Or be fixed at the lower perforation 5, a traction motor is arranged between the wire t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com