Drawing-type ring-network-cabinet-cable T-type head disassembling device

A ring network cabinet and pull-out technology, which is applied in the direction of equipment for connecting/terminating cables, can solve problems such as damage to the cabinet body and T-shaped joints, inconvenient cable maintenance, and inconvenient operation, so as to improve the efficiency of disassembly and maintenance and reduce Labor intensity, easy storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

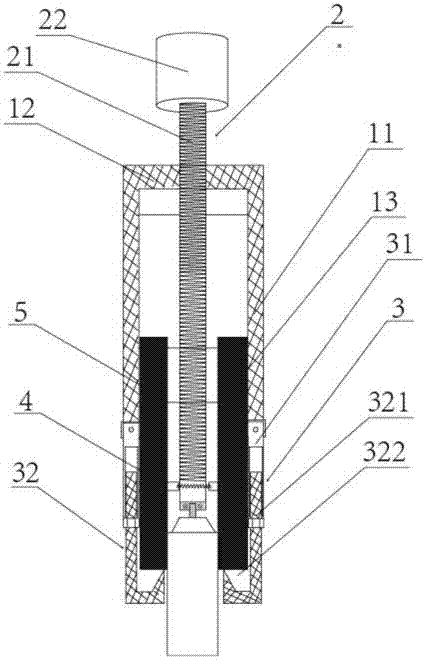

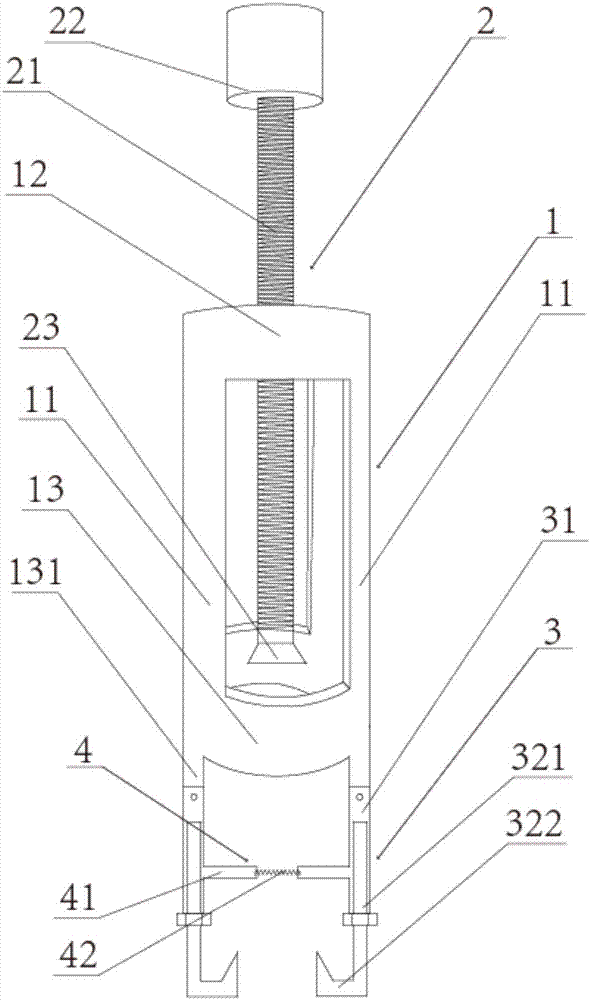

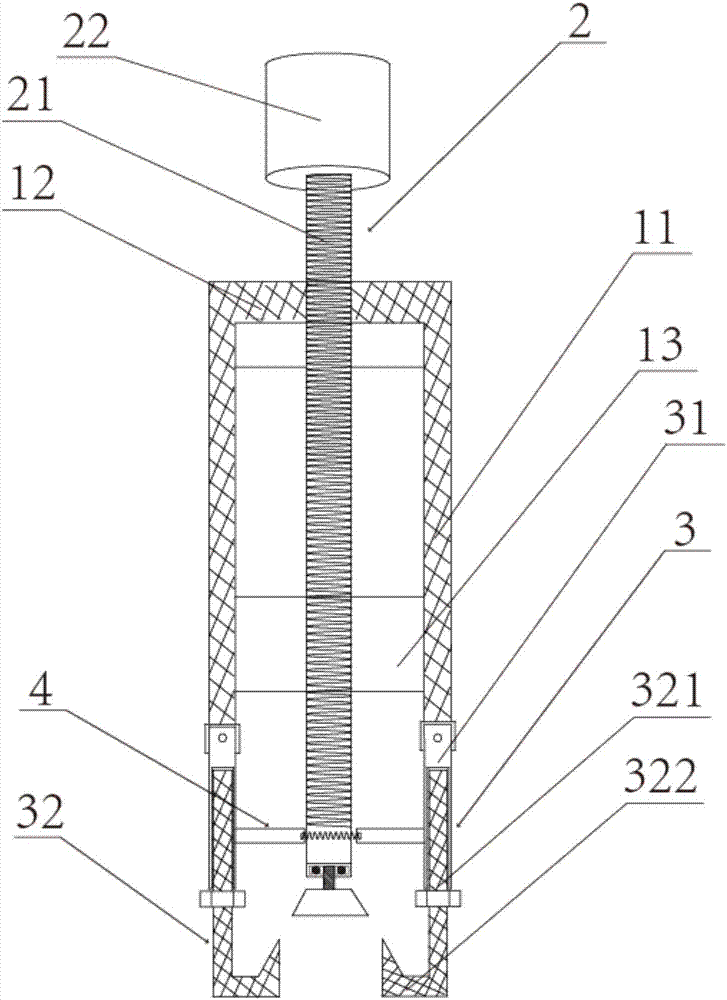

[0022] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

[0023] Such as Figure 1 to Figure 4 As shown, the pull-out type ring network cabinet cable T-head remover of the present invention includes a tubular base 1, a top pressure piece 2, an arc claw hook 3, an annular connector 4, a driver and a cable T-head 5, in.

[0024] The tubular base 1 is used to trap and position the cable T-head 5 that needs to be disassembled. The tubular base 1 is made of stainless steel or light-weight, high-strength aluminum alloy. The tubular base 1 includes at least two arc-shaped Equally divided support frame 11, tooling plate 12 and annular positioning sleeve 13, two support rods 11 are arranged vertically, tooling plate 12 is made of steel plate with a thickness of 30 mm and a diameter of 180 mm, tooling plate 12 and annular positioning sleeve 13 are all horizonta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com