Axial moving magnetic shielding type permanent magnetic speed regulator

A technology of permanent magnet governor and axial movement, which is applied in the direction of permanent magnet clutches/brakes, etc., which can solve the problems of large vibration, easy failure of permanent magnets, and large vibration of equipment, so as to achieve easy operation, stable and more reliable products and equipment , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

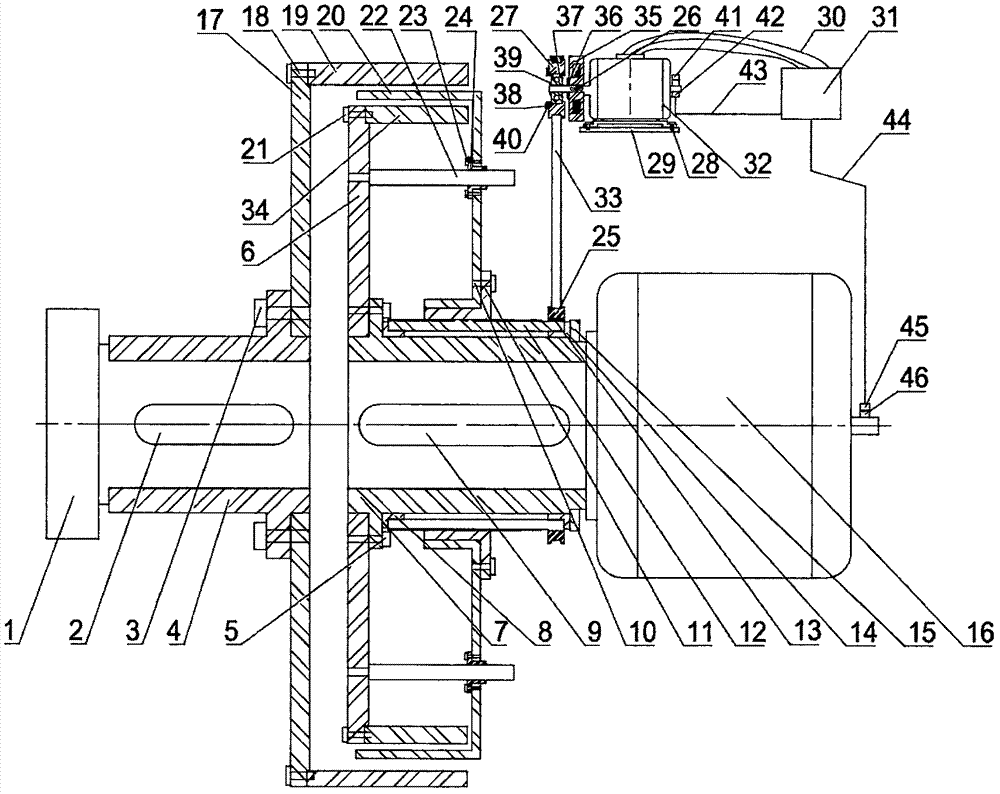

[0039] The axially moving magnetically shielded permanent magnet governor of this embodiment includes a cylindrical conductor rotor 19, a permanent magnet rotor 34 arranged on the inner periphery of the cylindrical conductor rotor 19, and a permanent magnet rotor 34 arranged between the conductor rotor 19 and the permanent magnet rotor 34. The axial movement of the magnetic shielding mechanism.

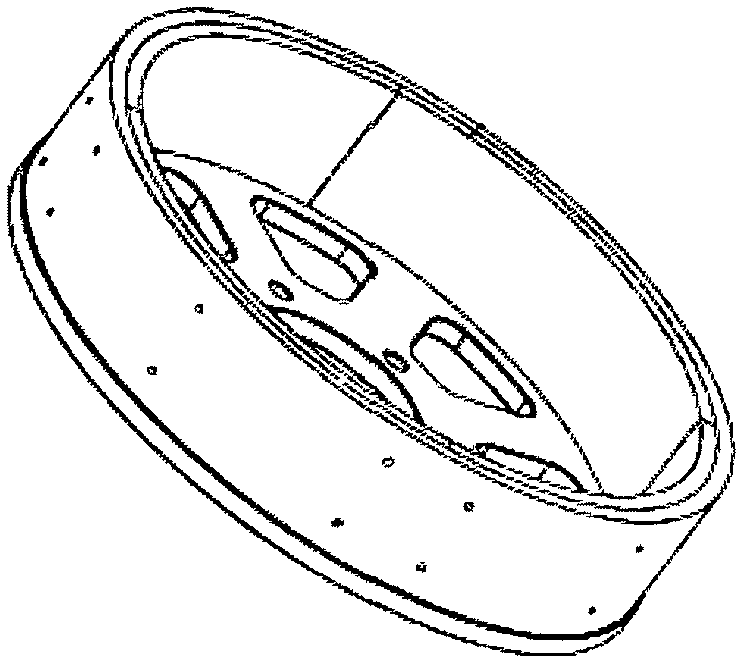

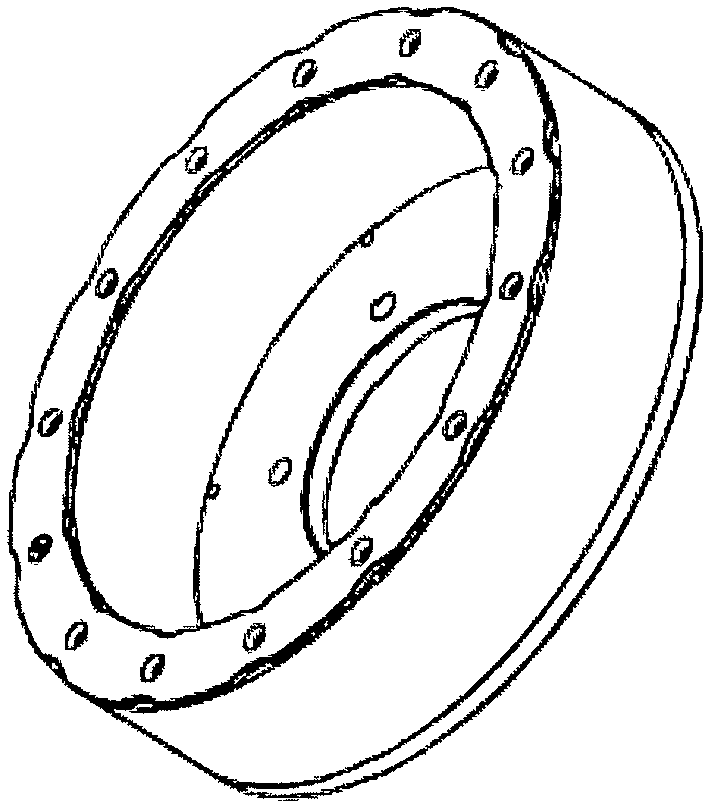

[0040] The cylindrical conductor rotor 19 is installed on the load shaft through the load coupling, and the outer circumference of the cylindrical conductor rotor 19 is equipped with a copper conductor ring, such as figure 2 shown. Among them, the permanent magnet rotor 34 is installed on the motor drive shaft through the drive shaft coupling, and the permanent magnet rotor 34 is provided with permanent magnets uniformly distributed along the circumference, and its schematic diagram is as follows image 3 shown. There is an air gap between the conductor rotor 19 and the permanent m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap