Electric appliance main contactor management circuit and method

A main contactor and circuit technology, which is applied in the field of vehicle control, can solve the problems of system efficiency reduction, system reliability reduction, noise, etc., and achieve the effect of prolonging service life and no oxidation of surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

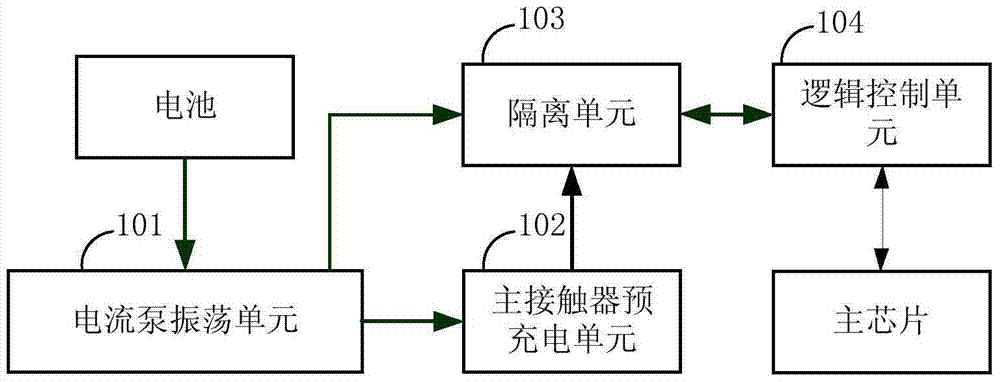

[0050] figure 1 A specific structural block diagram of the main contactor management circuit of the electrical appliance provided by Embodiment 1 of the present invention is shown. For the convenience of description, only the parts related to the embodiment of the present invention are shown. In this embodiment, the main contactor management circuit of the electrical appliance includes: a battery, a current pump oscillation unit 101, a main contactor pre-charging unit 102, an isolation unit 103, a logic control unit 104 and a main chip, wherein,

[0051] The current pump oscillating unit 101 is used to amplify the current through the push-pull circuit to continuously charge the first capacitor, and keep the voltage value of the second capacitor at the output end of the first capacitor not lower than a preset value;

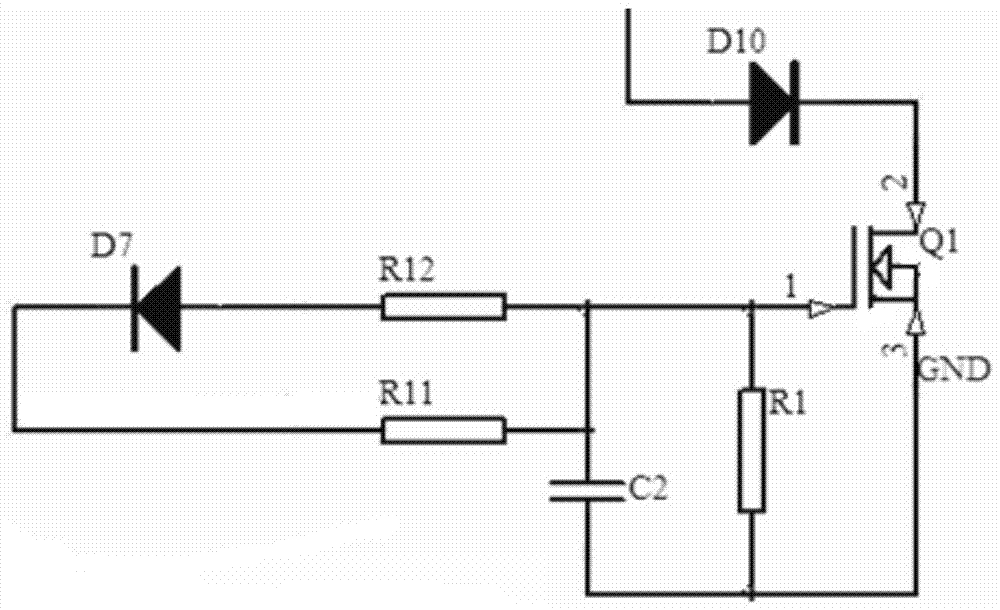

[0052] The main contactor pre-charging unit 102 is used to use the transistor as the main contactor when charging the second capacitor when powered on, and realiz...

Embodiment 2

[0073] Image 6 It shows the implementation process of the main contactor management method of electrical appliances provided by Embodiment 2 of the present invention, and the details are as follows:

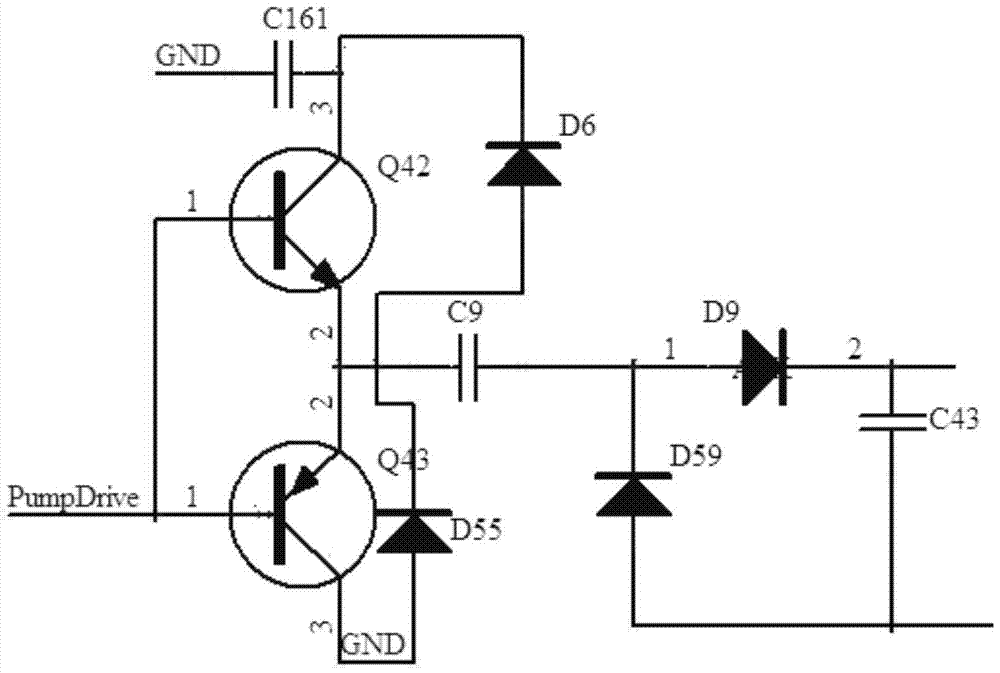

[0074] In step S601 , the push-pull circuit performs current amplification to continuously charge the first capacitor, and keeps the voltage value of the second capacitor at the output end of the first capacitor not lower than a preset value.

[0075] In this embodiment, this step consists of figure 2 The circuit shown is completed, specifically, the PNP transistor Q42 and the NPN transistor Q43, the base of the PNP transistor Q42 and the base of the NPN transistor Q43 are respectively connected to the input electrical signal, and the collector of the PNP transistor Q42 is connected to the third parallel connection. One end of the capacitor C161 is connected to the negative pole of the first diode D6, the emitter of the PNP transistor Q42 is respectively connected to the emitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com