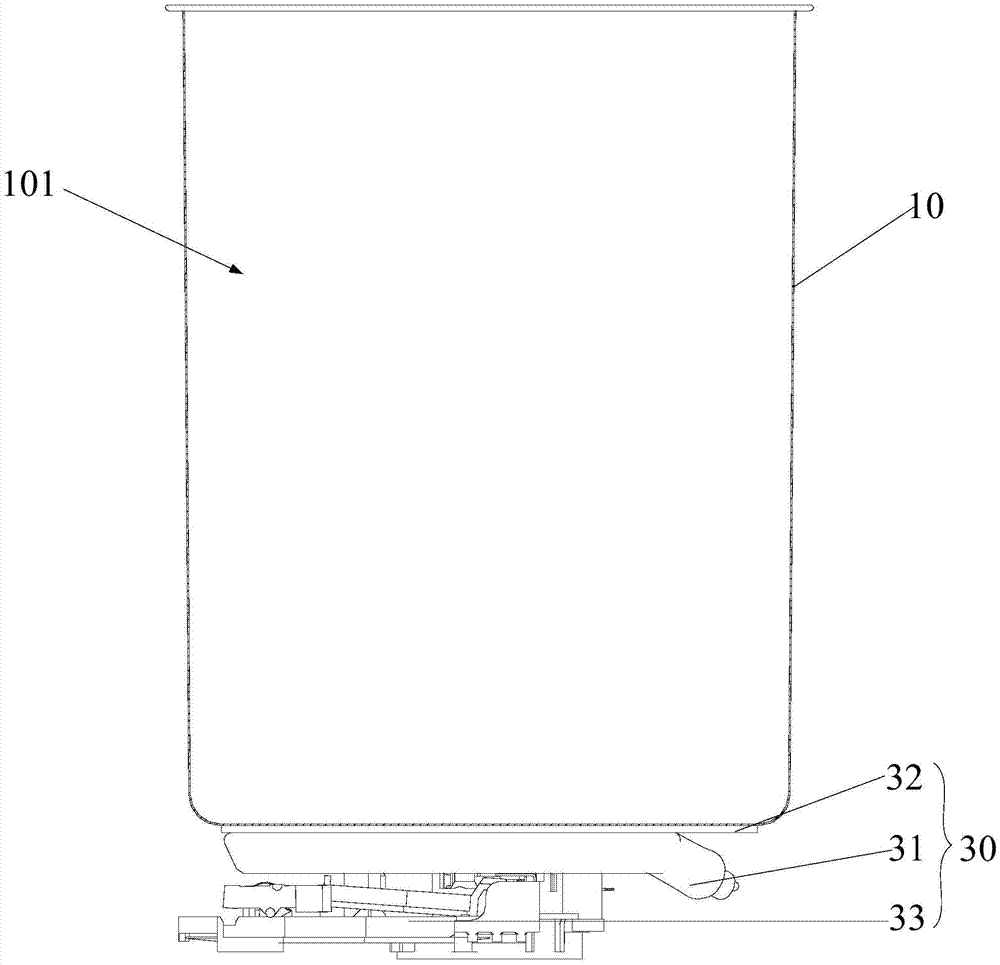

Liquid heating container

A liquid heating container and liquid technology, which is applied to cooking utensils, water-boiling utensils, special materials for cooking utensils, etc. The effect of increasing market competitiveness and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

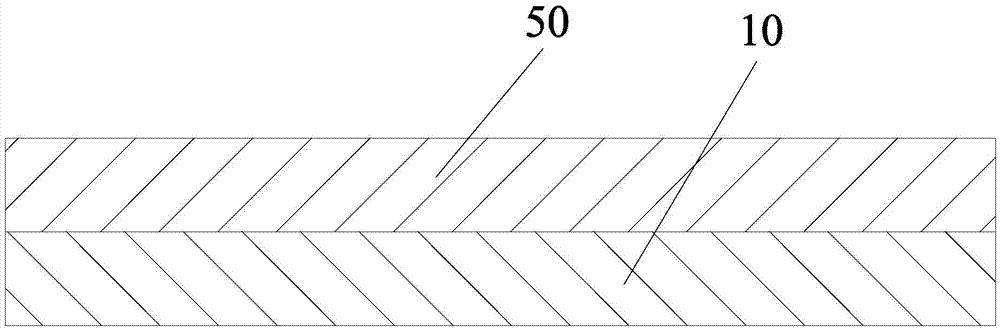

[0117] The body of the surface-treated kettle has a fluorine-containing coating, the thermal conductivity of the coating is 0.35W / (m·K), the thickness of the coating is 20μm, the hardness is 3H, and the contact angle with the coating is 103° , The kettle heating power is 1500W, and the heating power density is 12W / cm 2 , The maximum temperature of the heating plate surface when the kettle is boiling normally is 105℃, the maximum noise during the kettle boiling process is 51dB, and the noise of the kettle without surface treatment is 62dB, which has a good noise reduction effect.

specific Embodiment 2

[0119] The container body of the surface-treated kettle has a ceramic coating, the thermal conductivity of the coating is 1.0W / (m·K), the thickness of the coating is 30μm, the hardness is 6H, the contact angle with the coating is 108°, the heating power of the kettle 1800W, heating power density is 15W / cm 2 , The maximum temperature of the heating plate surface when the kettle is boiling normally is 110°C, the maximum noise during the kettle boiling process is 52dB, and the noise of the kettle without surface treatment is 62dB, which has a good noise reduction effect.

[0120] To sum up, in the liquid heating container provided by the present invention, the thermal conductivity of the coating on the inner wall of the container body is 0.2W / (m·K)~10W / (m·K), which avoids that the thermal conductivity is too small, causing the coating The layer affects the efficiency of the liquid heating vessel, and at the same time prevents the phenomenon that the thermal conductivity is too large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com