Coal blocking early warning and automatic processing device and method for medium-speed coal mill

An automatic processing and coal mill technology, applied in the field of coal mills, can solve the problems of coal mill blockage, incomplete system isolation, singleness, etc., and achieve the effect of preventing the expansion of accidents and promoting safe and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

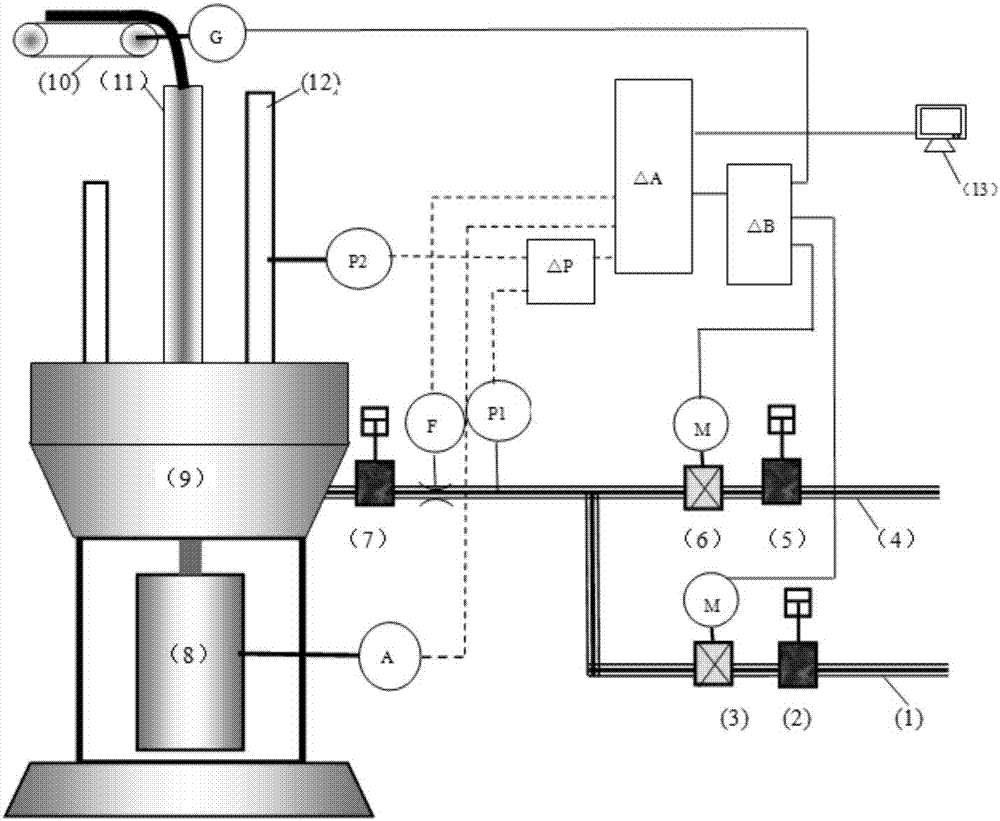

[0054] figure 2 It is a structural schematic diagram of Embodiment 1 of a medium-speed coal pulverizer coal blocking early warning and automatic processing device.

[0055] Such as figure 2 As shown, the coal blocking early warning and automatic processing device of the medium-speed coal mill, the cold air in the cold air duct and the hot air in the hot air duct are mixed and then passed into the medium-speed coal mill; the cold air duct and the hot air duct are respectively equipped with cold air control doors and a hot air control door, the cold air control door and the hot air control door are both connected to the controller;

[0056] The coal blocking early warning and automatic processing device of the medium-speed coal mill includes:

[0057] a first pressure sensor and a flow sensor respectively arranged on the inlet pipeline of the coal mill; and

[0058] A second pressure sensor arranged on the outlet pipeline of the coal mill;

[0059] The first pressure senso...

Embodiment 2

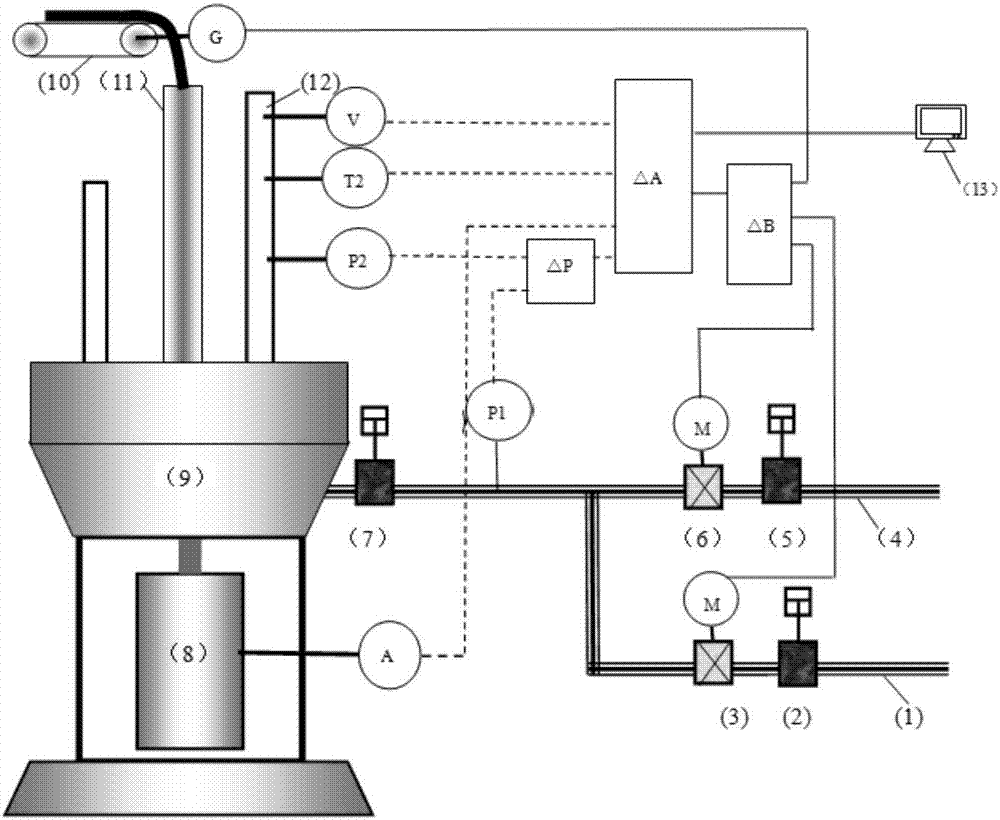

[0076] image 3 It is a structural schematic diagram of Embodiment 2 of the medium-speed coal pulverizer coal blocking early warning and automatic processing device.

[0077] Such as image 3 As shown, in the medium-speed coal mill coal blocking early warning and automatic processing device of the present embodiment, the cold air in the cold air duct is mixed with the hot air in the hot air duct and then passed into the medium-speed coal mill; the cold air duct and the hot air duct are respectively A cold air control door and a hot air control door are installed, and the cold air control door and the hot air control door are connected to the controller;

[0078] The coal blocking early warning and automatic processing device of the medium-speed coal mill includes:

[0079] a first pressure sensor arranged on the inlet pipe of the coal mill; and

[0080] A temperature sensor, a second pressure sensor and a wind speed sensor respectively arranged on the outlet pipeline of the...

Embodiment 3

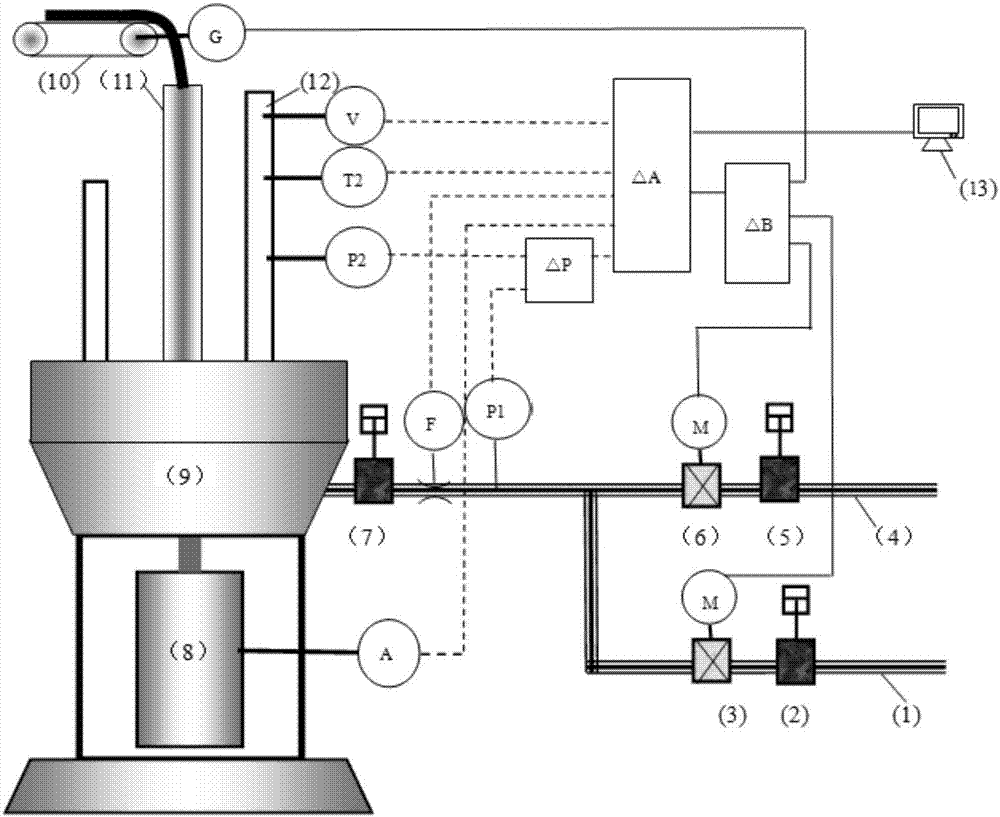

[0098] Figure 4 It is a structural schematic diagram of Embodiment 3 of a medium-speed coal pulverizer coal blocking early warning and automatic processing device.

[0099] Such as Figure 4As shown, in the medium-speed coal mill coal blocking early warning and automatic processing device of the present embodiment, the cold air in the cold air duct is mixed with the hot air in the hot air duct and then passed into the medium-speed coal mill; the cold air duct and the hot air duct are respectively A cold air control door and a hot air control door are installed, and the cold air control door and the hot air control door are connected to the controller;

[0100] The coal blocking early warning and automatic processing device of the medium-speed coal mill includes:

[0101] a first pressure sensor and a flow sensor respectively arranged on the inlet pipeline of the coal mill; and

[0102] A temperature sensor, a second pressure sensor and a wind speed sensor respectively arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com