Plate turnover machine

A technology of turning machine and turning mechanism, which is applied in the field of turning machine, can solve the problems of affecting work progress, gear friction noise pollution, heavy equipment, etc., so as to save production and manufacturing costs, avoid gear friction sound, and require low machine height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

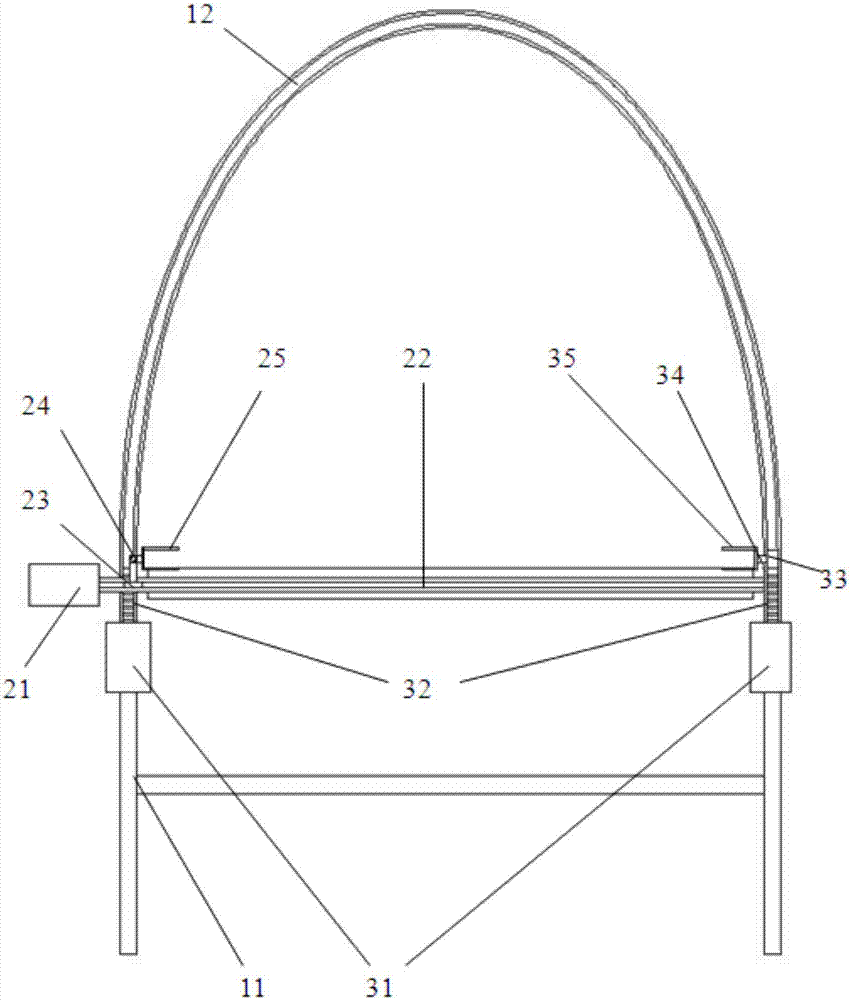

[0037] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those embodiments can be easily realized by those having ordinary skill in the art to which the invention pertains. However, the present invention can also be realized in various forms, so the present invention is not limited to the embodiments described hereinafter. In addition, in order to describe the present invention more clearly, parts not connected with the present invention will be omitted from the drawings.

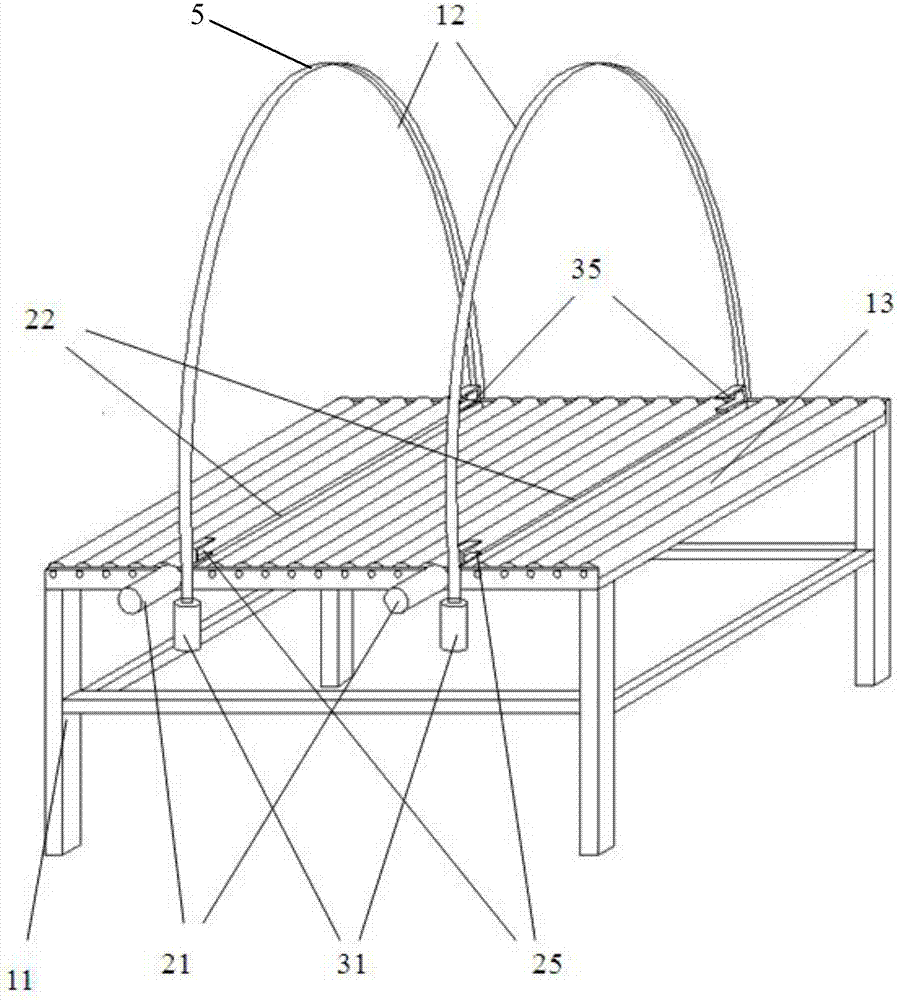

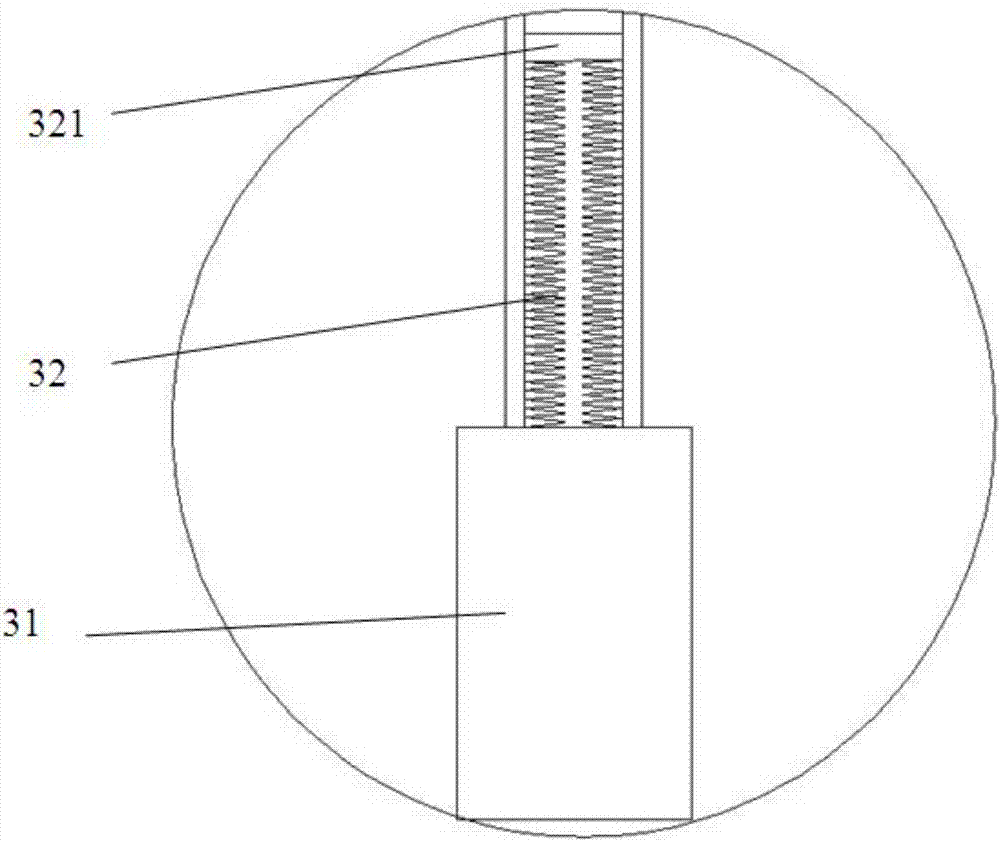

[0038] The turning machine includes: turning mechanism 1 and turning mechanism 2 with the same structure (since the turning mechanism 1 and turning mechanism 2 have the same structure, so when describing the content of the present invention, only turning mechanism 1 is used as an example for description) , the distance between the turning mechanism 1 and the turning mechanism 2 along the idler frame is less than the length of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com