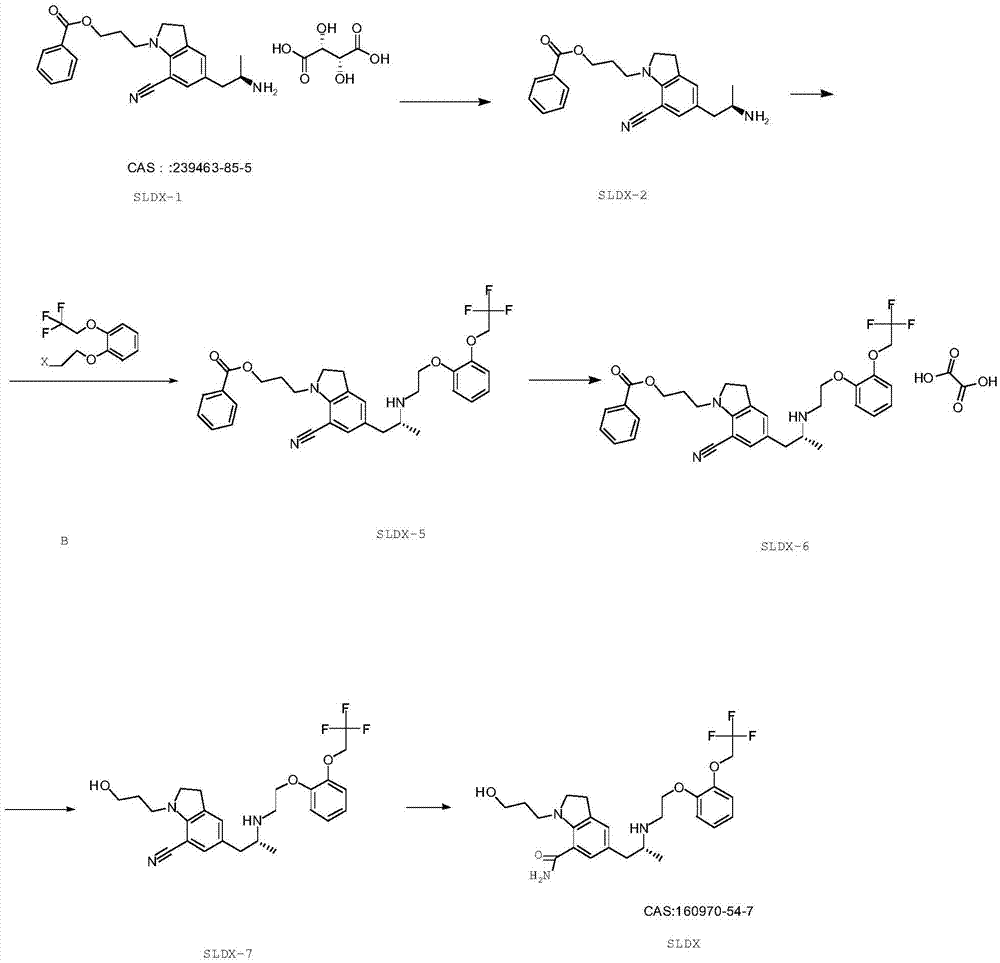

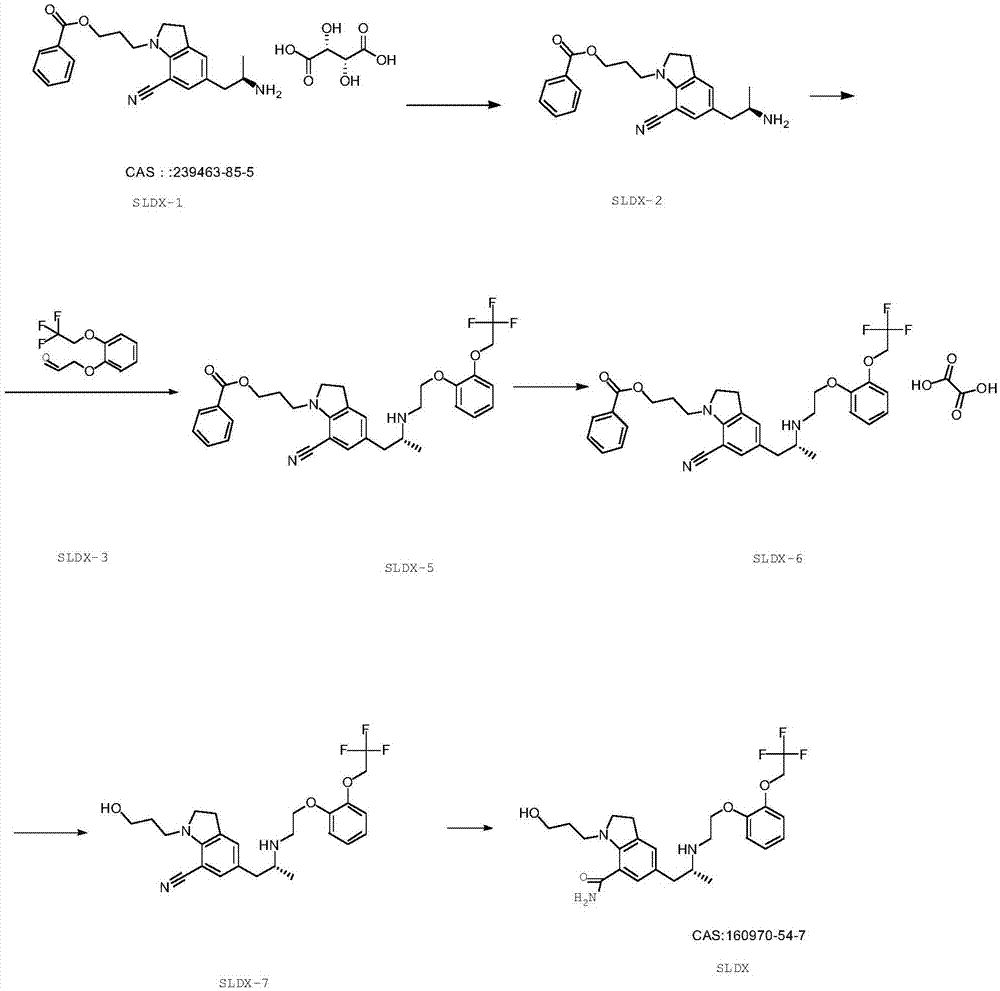

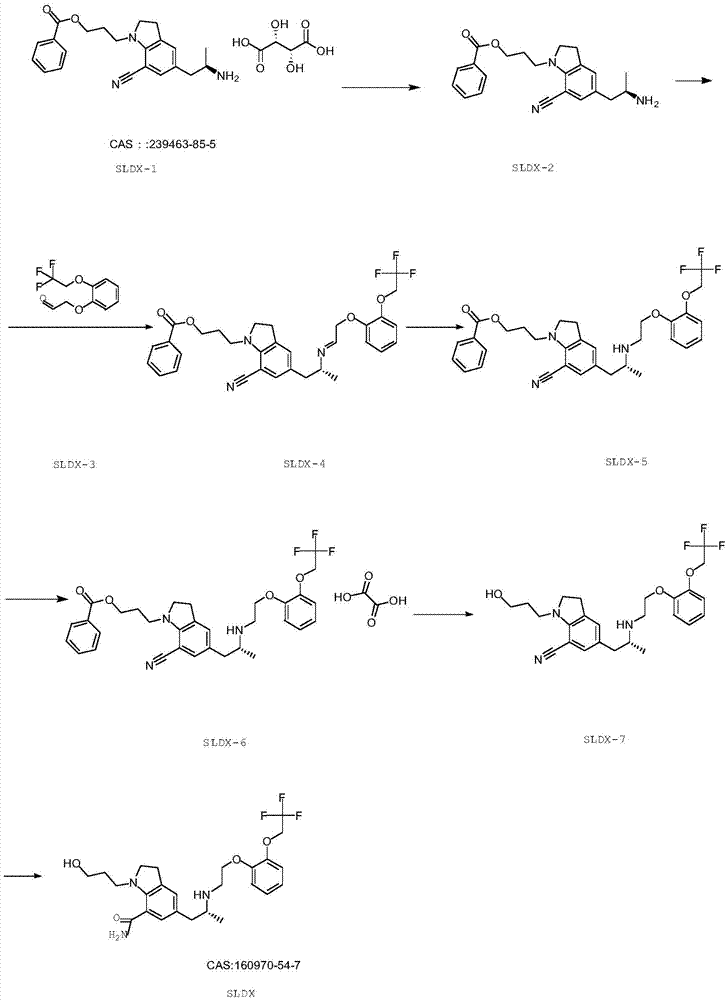

Method for preparing silodosin

A technology of silodosin and dihydrogen, which is applied in the field of medicinal chemistry synthesis, can solve the problems of difficult purification and low yield, and achieve the effects of simplifying product purification procedures, improving product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: Preparation of silodosin

[0044] Step 1: Preparation of 5-[(2R)-2-aminopropyl]-2,3-dihydro-1-[3-(benzoyloxy)propyl]-1H-indole-7-carbonitrile

[0045] 1. Add 80L of water into a 200L reactor, add 6.2Kg of sodium carbonate and stir until clear;

[0046] 2. Add 50L of ethyl acetate, stir, add 5-[(2R)-2-aminopropyl]-2,3-dihydro-1-[3-(benzoyloxy)propyl]-1H- Indole-7-carbonitrile tartrate 10Kg, stirred for 2 hours;

[0047] 3. Stand still to separate the liquid, extract the aqueous phase with 20L ethyl acetate once, and combine the organic phase;

[0048] 4. The organic phase was washed twice with 15L saturated brine, and the organic phase was dried with anhydrous sodium sulfate for 4 hours;

[0049] 5. Suction filtration, the desiccant was washed with ethyl acetate; the solvent was collected under reduced pressure to obtain 7Kg of oil, which was 5-[(2R)-2-aminopropyl]-2,3-dihydro-1-[3 -(Benzoyloxy)propyl]-1H-indole-7-carbonitrile, the yield is about 99%. ...

Embodiment 2

[0078] Embodiment 2: preparation of silodosin

[0079] Step 1: Preparation of 5-[(2R)-2-aminopropyl]-2,3-dihydro-1-[3-(benzoyloxy)propyl]-1H-indole-7-carbonitrile

[0080] 1. Add 80L of water into a 200L reactor, add 6.2Kg of sodium carbonate and stir until clear;

[0081] 2. Add 50L of ethyl acetate, stir, add 5-[(2R)-2-aminopropyl]-2,3-dihydro-1-[3-(benzoyloxy)propyl]-1H- Indole-7-carbonitrile tartrate 10Kg, stirred for 2 hours;

[0082] 3. Stand still to separate the liquid, extract the aqueous phase with 20L ethyl acetate once, and combine the organic phase;

[0083] 4. The organic phase was washed twice with 15L saturated brine, and the organic phase was dried with anhydrous sodium sulfate for 4 hours;

[0084] 5. Suction filtration, the desiccant was washed with ethyl acetate; the solvent was collected under reduced pressure to obtain 7Kg of oil, which was 5-[(2R)-2-aminopropyl]-2,3-dihydro-1-[3 -(Benzoyloxy)propyl]-1H-indole-7-carbonitrile, the yield is about 99%. ...

Embodiment 3

[0113] Embodiment 3: preparation of silodosin

[0114] Step 1: Preparation of 5-[(2R)-2-aminopropyl]-2,3-dihydro-1-[3-(benzoyloxy)propyl]-1H-indole-7-carbonitrile

[0115] 1. Add 80L of water into a 200L reactor, add 6.2Kg of sodium carbonate and stir until clear;

[0116] 2. Add 50L of ethyl acetate, stir, add 5-[(2R)-2-aminopropyl]-2,3-dihydro-1-[3-(benzoyloxy)propyl]-1H- Indole-7-carbonitrile tartrate 10Kg, stirred for 2 hours;

[0117] 3. Stand still to separate the liquid, extract the aqueous phase with 20L ethyl acetate once, and combine the organic phase;

[0118] 4. The organic phase was washed twice with 15L saturated brine, and the organic phase was dried with anhydrous sodium sulfate for 4 hours;

[0119] 5. Suction filtration, the desiccant was washed with ethyl acetate; the solvent was collected under reduced pressure to obtain 7Kg of oil, which was 5-[(2R)-2-aminopropyl]-2,3-dihydro-1-[3 -(Benzoyloxy)propyl]-1H-indole-7-carbonitrile, the yield is about 99%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com