Washing agent input control method and washing machine

A technology of detergent feeding and control method, applied in the field of washing machines, can solve the problems of inability to achieve accurate feeding of washing machines, influence of laundry washing and rinsing effects, failure to achieve laundry washing effects, etc., so as to avoid insufficient or excessive doses, The effect of improving washing and rinsing effect and improving laundry efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

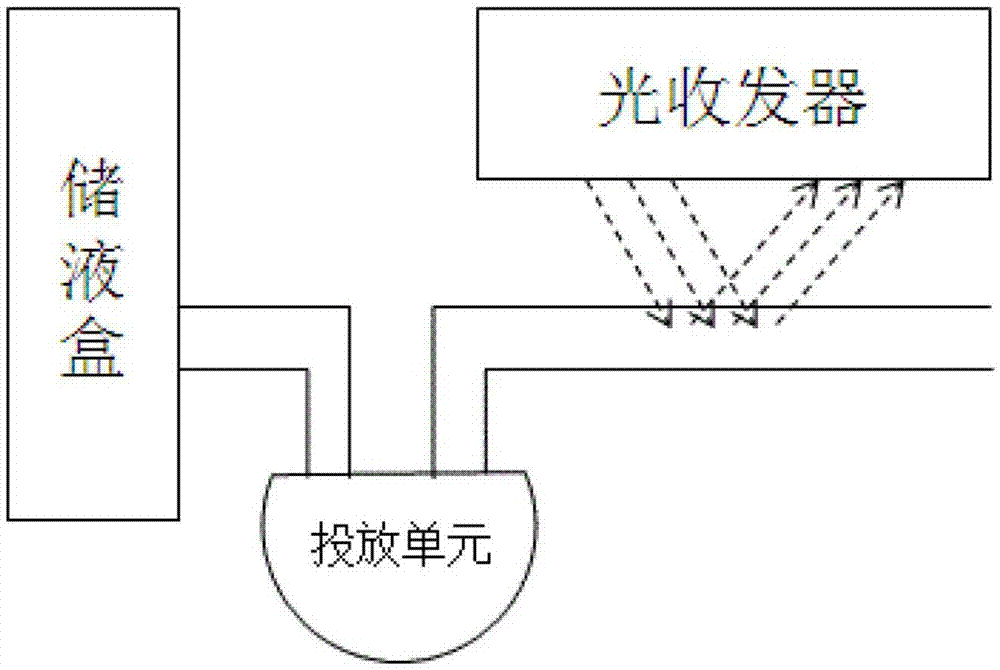

[0048] Such as figure 1 As shown, a washing machine according to the present invention includes a control module and an automatic detergent dispensing device, the automatic detergent dispensing device includes an optical transceiver, and the optical transceiver is connected to the control module; the washing machine control module receives The detergent detection information sent by the optical transceiver obtains the concentration of the detergent, determines the dosage, and controls the automatic detergent dispensing device to dispense. The detergent automatic dispensing device also includes a liquid storage box and a dispensing unit; the liquid storage box, the dispensing unit and the dispensing unit are connected to the water inlet box of the washing machine through an infusion tube, and the optical transceiver is arranged in the infusion solution pipe on.

[0049]Wherein, the optical transceiver set on the infusion line of detergent can be set on the infusion tube betwee...

Embodiment 2

[0065] In this embodiment, it is also possible to use a dosing unit with a pump structure, which is connected to the control module, and the control module determines its working parameters. The working parameters described therein are mainly power and current parameters.

[0066] Specifically, the delivery unit is firstly set with a fixed length and / or liquid level difference during installation. When the delivery unit injects washing liquid, it judges the viscosity of the delivery liquid according to the power / current of the delivery unit, which is obtained from the experimental results. : When the viscosity of the detergent is higher, the power / current of the dosing unit is greater; when the viscosity of the detergent is lower, the power / current of the dosing unit is smaller.

[0067] Preferably, the power cord of the delivery unit of the pump structure is connected to the control module, and the control module provides working power for the delivery unit, by detecting para...

Embodiment 3

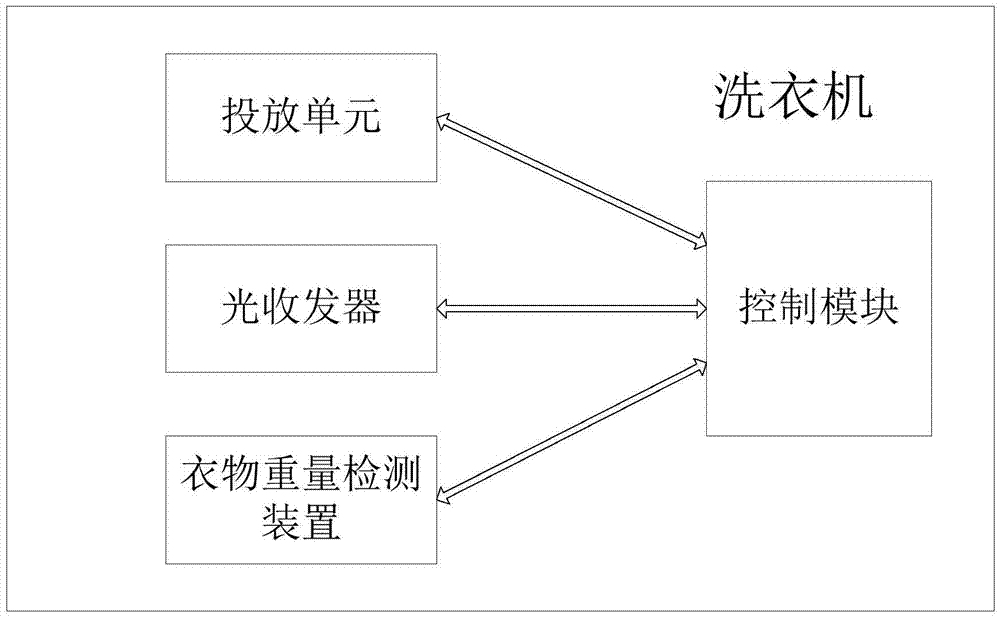

[0071] Such as figure 2 As shown, the washing machine described in this embodiment also includes a clothes weight detection device connected to the control module;

[0072] Wherein, the clothes weight detection device automatically weighs the clothes put into the washing machine to obtain the clothes load.

[0073] Specifically, when the user puts the laundry into the washing tub, the laundry weight detection device can automatically detect the weight of the laundry, and calculate the current laundry load of the washing machine.

[0074] Further, the detected laundry load is directly sent to the washing machine control module for processing.

[0075] Alternatively, the washing machine further includes a wireless module, through which the washing machine can use a network connection to connect to the service platform corresponding to the washing machine through the network, and send it to the service platform processing station through the wireless module arranged on the wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com