Integrated foam type headrest having different hardnesses, and manufacturing method thereof

一种泡沫型、头枕的技术,应用在头枕、车辆的特殊位置、车辆部件等方向,能够解决头枕批量生产和质量劣化、乘客头部不舒服、稳定性和舒适度降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

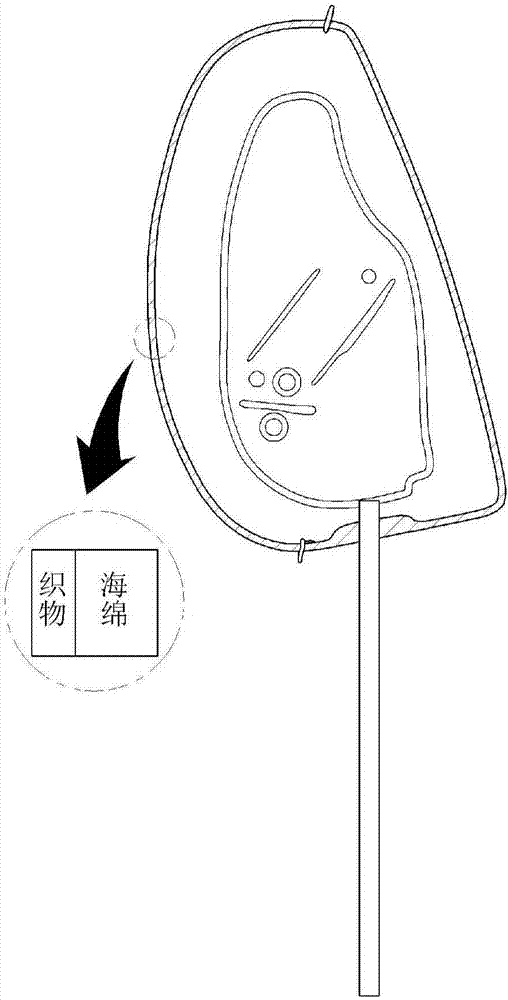

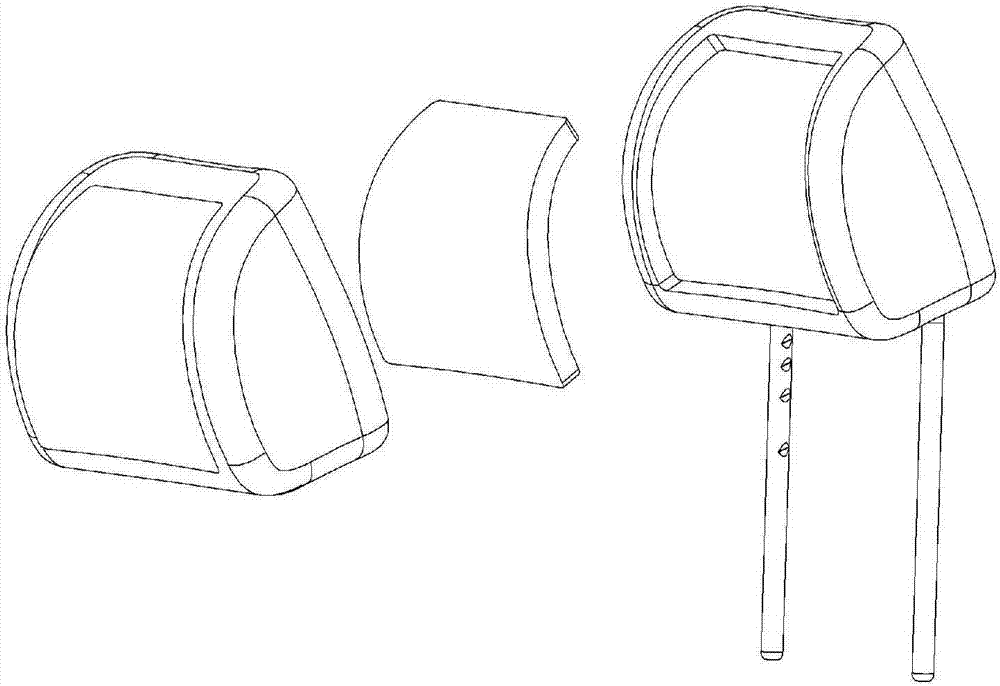

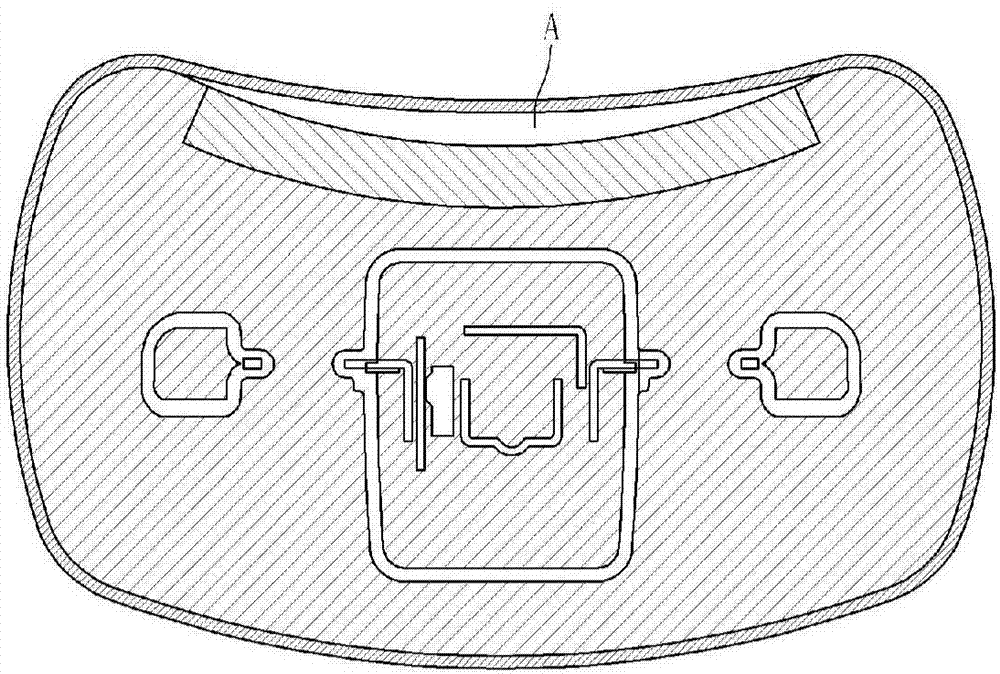

[0031] The integrated foam-type headrest having different hardness portions according to the present invention includes: a headrest cover; a cushion member made of a material having high elongation and low resilience, and attached to the foamed material before foaming The inner surface of the cover; the partition member, which is attached to the inner surface of the cushion member, and prevents the foam material from penetrating into the cushion member; the holding frame, which installs the headrest to the seat; and the foam material, which is Instead, it surrounds the retaining frame and is filled in the headrest cover.

[0032] Here, the cushion member is a memory foam having a high elongation and a resilience of 5% to 15%, or a sponge having a high elongation and a resilience of 50% or less. A typical sponge has a high stiffness at a high density, but a typical memory foam has a low stiffness at a high density and a high elongation.

[0033] Here, the partition member is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com