Thermal insulation system using evaporative cooling

A technology of vapor cooling and isolation layer, which is applied in the direction of heat insulation protection pipeline, heat transfer modification, heat exchange equipment, etc., which can solve the problems of water evaporation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

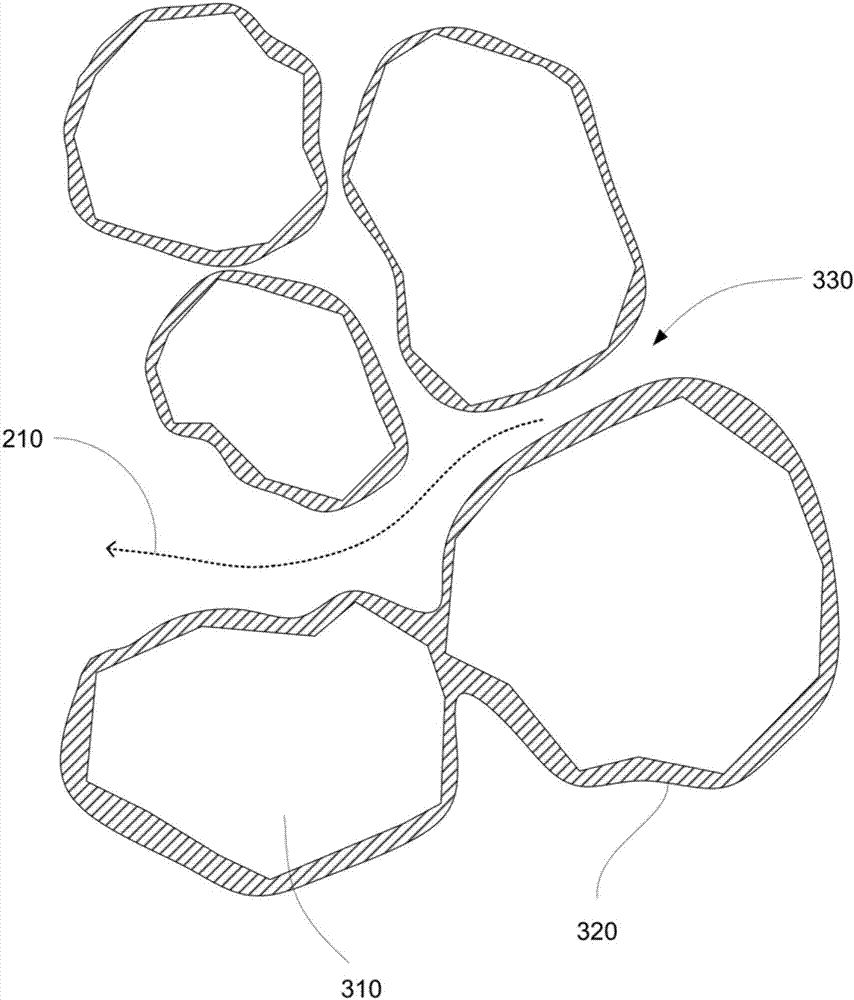

[0078] Granular dry mineral material has a specific heat of approximately 0.25 Btu / lb-°F. Over a range of temperatures, water has a specific heat of about 1.0 Btu / lb-°F and a latent heat of vaporization of water of 970 Btu / lb (at boiling point). Thus, heating dry material from 70°F to 200°F (a difference of 130 degrees) requires only 32.5 Btu / lb (130 x 0.25), while heating and boiling water requires 1100 Btu / lb (130 x 1.0+970). If the material is wetted with water to the extent of 10% by weight, the heat required to raise the temperature to 200°F and dry the material is 139.25 Btu / lb (0.9 x 130 x 0.25 + 0.1 x 1100). Therefore, the heat required to raise the temperature of the wet material (10% water) to the boiling point of water and evaporate the water is more than 4 times that required for the dry material. This results in a significant increase in isolation when the heat source is of limited duration and volume.

[0079] For the example described above, the dry barrier ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com