3D print template for surgical puncture and preparation method

A 3D printing and template technology, applied in the field of puncture surgery, can solve the problems of increasing patient pain and radiation exposure time of the surgeon and the patient, the inability of the patient to make a specific diagnosis, and the inability to predict whether the nerve roots are parallel, etc., to reduce radiation exposure time, clarification of surgical feasibility, and effect of reduction in surgical time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

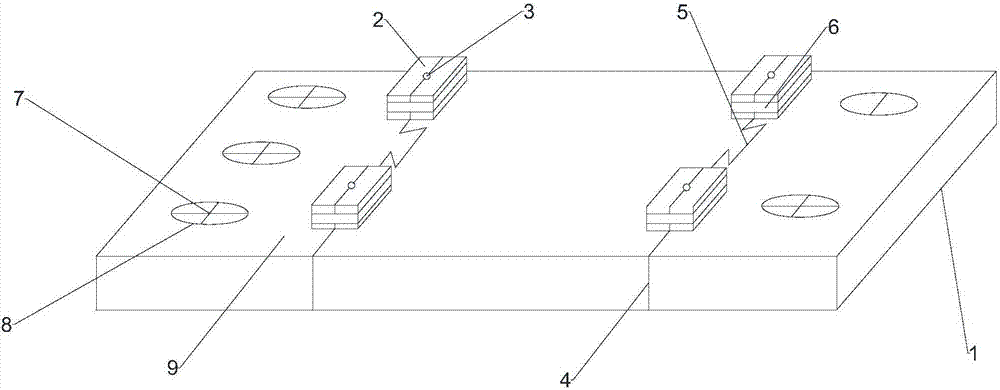

[0030] Please refer to figure 1 , this implementation provides a 3D printing template for surgical puncture.

[0031] The 3D printing template includes a board body 1 and several cylinders 2 with puncture holes 3, the board body 1 is assembled from a number of board body pieces 9; the cylinders 2 are all located on the same side of the board body and set It is located at the joint 4 between the board body blocks 9 and is divided by the joint 4; the outside of the column 2 is provided with an outer ring 6, and the two can slide relative to each other; the board body is constructed with a positioning ring 8.

[0032] A dovetail 5 is formed at the edge of the connection between the board body blocks 9 , and the embedded dovetail 5 structure can make the connection between the board body blocks 9 tighter, and also improve the overall strength of the board body.

[0033] The puncture hole 3 is configured in the center of the column body 2, and the seam 4 passes through the punctur...

Embodiment 2

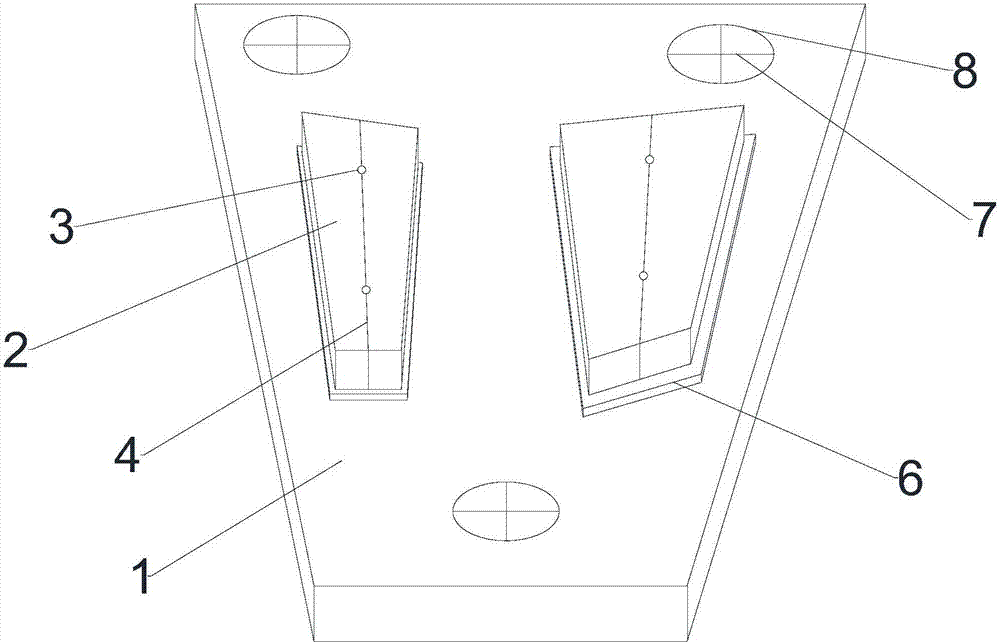

[0052] Please refer to figure 2 , this implementation provides a 3D printing template for surgical puncture.

[0053] The 3D printing template includes a board body 1 and several detachable cylinders 2 with puncture holes 3; an outer ring 6 is constructed on the board body 1, and the outer ring 6 is arranged on the same side of the board body 1, and the board body 1 The part surrounded by the outer ring 6 is hollowed out to facilitate the installation of the cylinder 2.

[0054] The cylinder 2 is embedded in the outer ring 6 and fixed by the outer ring 6 . The seam 4 passes through the puncture hole 3 on the column 2 to divide the column 2 . The split and detachable cylinder 2 makes it possible to remove the puncture template when the puncture needle is inserted into the puncture hole 3 while retaining the puncture needle during use.

[0055] The positioning ring 8 constructed on the board needs to coincide with the position marked on the patient's buttocks when the template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com