Magazine-like dust collecting apparatus with filter drums

A kind of dust collection equipment and clip-type technology, which is applied in the direction of dispersed particle filtration, climate change adaptation, and climate sustainability. Even flow filter cartridges and other issues, to ensure the filtration area and filtration effect, increase the service life, and the effect of good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

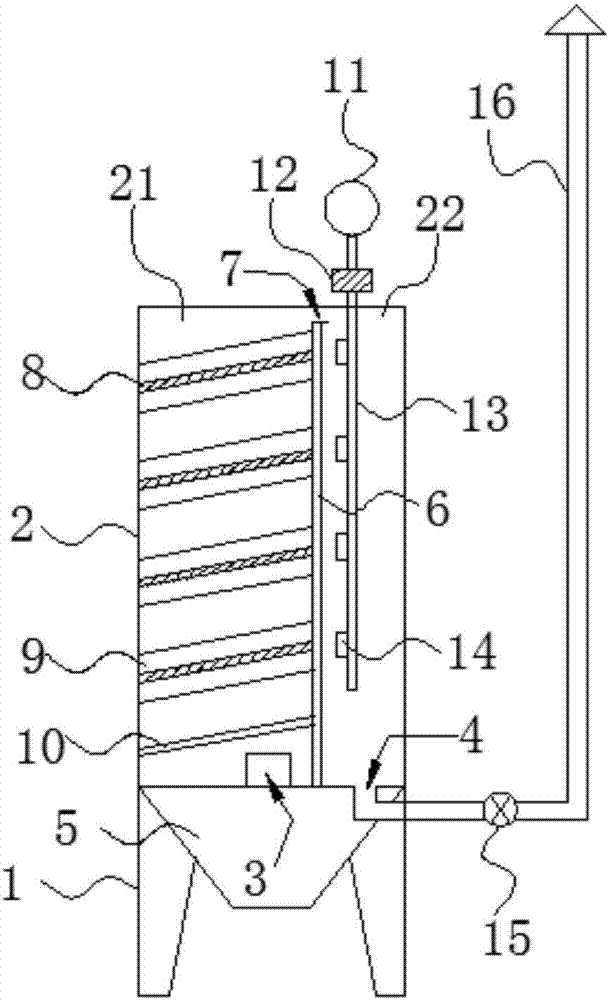

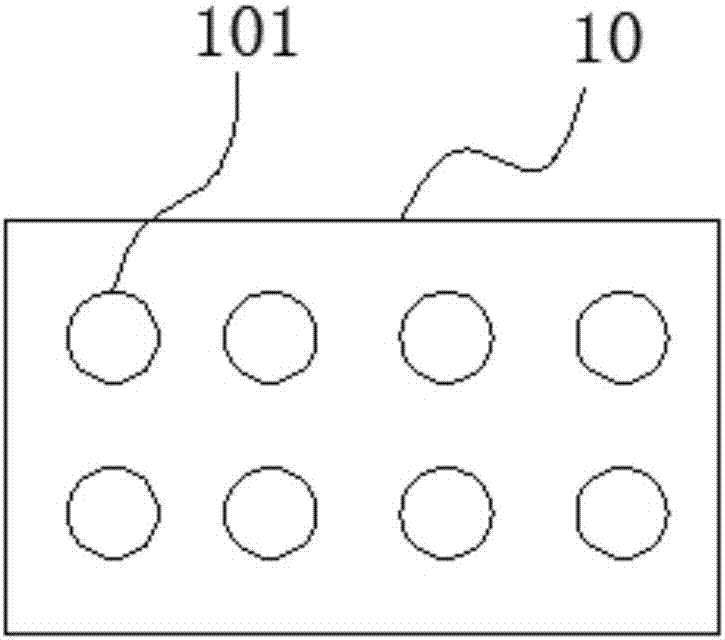

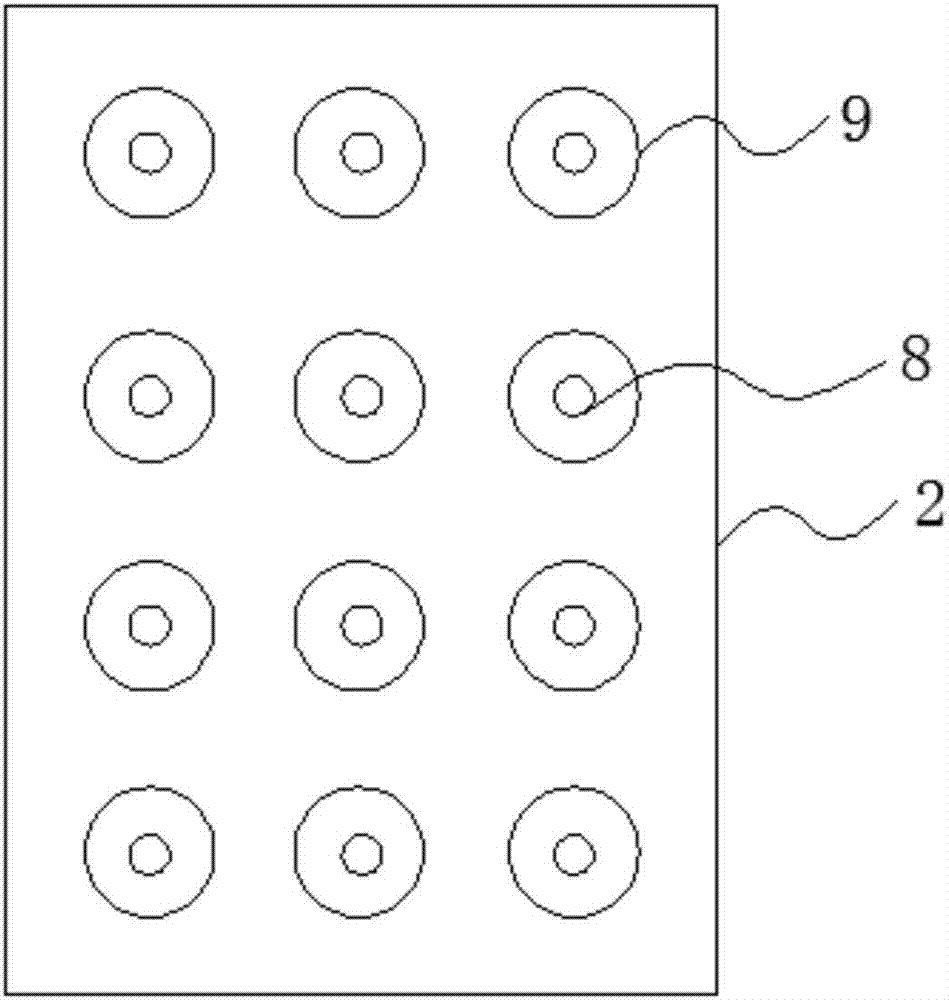

[0027] Embodiment: a kind of cartridge type filter cartridge dust collection equipment, such as Figure 1-3 As shown, it includes a bracket 1, a cylinder body 2, an exhaust gas inlet 3, a clean gas outlet 4, and a dust collecting bucket 5. The cylinder body 2 is installed on the bracket 1, and the exhaust gas inlet 3 is located at the The rear side wall of the cylinder body 2, the clean gas outlet 4 is located at the lower side wall of the cylinder body 2, and the dust collecting hopper 5 is located below the cylinder body 2;

[0028] The interior of the cylinder body 2 is provided with a partition plate 6 perpendicular to the bottom of the cylinder body 2, and a dust collection chamber communicated with the exhaust gas inlet 3 is respectively formed on the left and right sides of the partition plate 6 21 and the clean room 22 communicated with the clean air outlet 4, the upper end of the partition plate 6 is provided with an outlet 7, the outlet 7 communicates with the dust c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap