Dry and wet integrated desulfurization and denitrification device

A technology for desulfurization, denitrification and dry desulfurization, which is applied in gas treatment, chemical instruments and methods, combustion product treatment, etc. It can solve the problems of inability to meet ultra-low emissions, large dosage, and poor removal effect, and achieve quick results. , strong desulfurization and denitrification ability, and the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

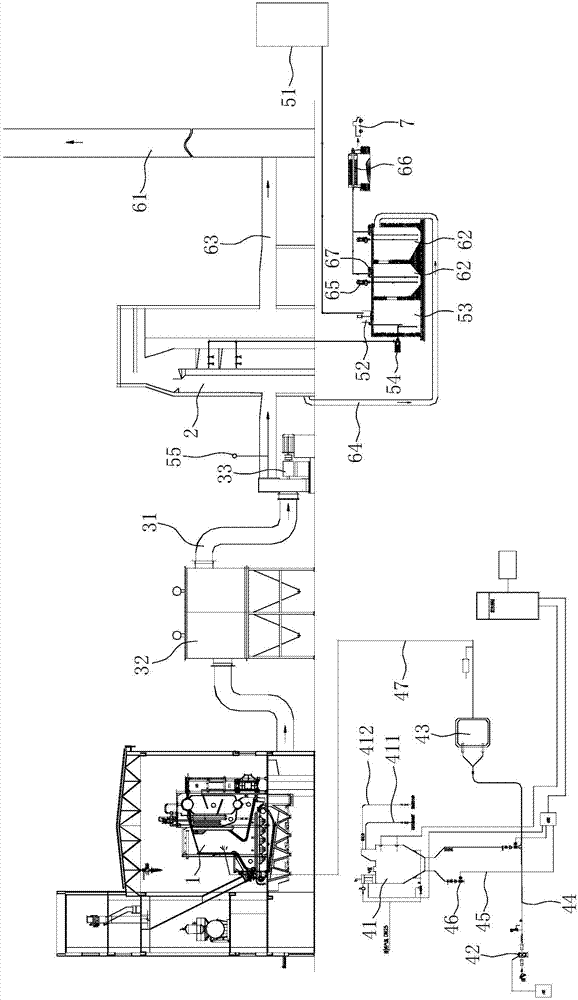

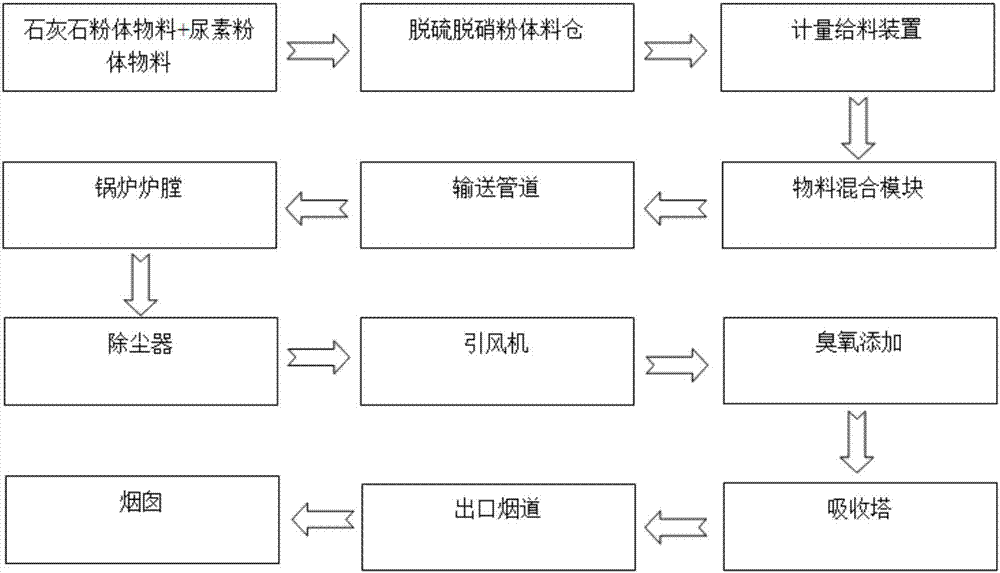

[0032] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 .

[0033] The dry-wet integrated desulfurization and denitrification device of the present invention includes:

[0034] Boiler or kiln 1, as the implementation site of dry desulfurization and denitrification treatment;

[0035] The absorption tower 2 is used as an implementation place for wet desulfurization and denitrification treatment;

[0036] The dry feeding mechanism is connected with the boiler or kiln 1, and is used to add the removal agent used for dry desulfurization and denitrification into the boiler or kiln 1;

[0037] The wet feeding mechanism is connected with the absorption tower 2, and is used to add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com