Automatic gelatin pill mixing and toning device and method

A color matching device and technology for capsules, applied in chemical instruments and methods, mixers with rotary stirring devices, mixers, etc., can solve the problems of uncontrollable color difference of capsules, unable to guarantee the quality of color matching, etc., and reduce manpower. Resource consumption, reduction of occupational hazards, controllable effects of color difference and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

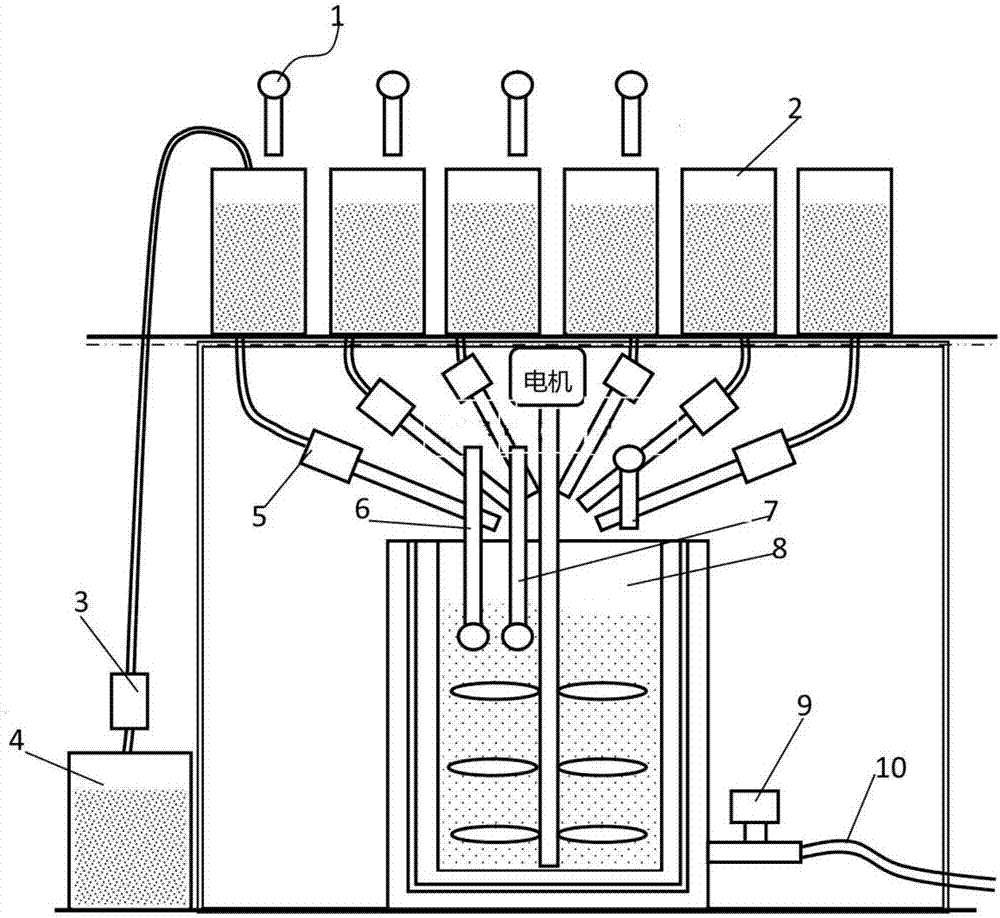

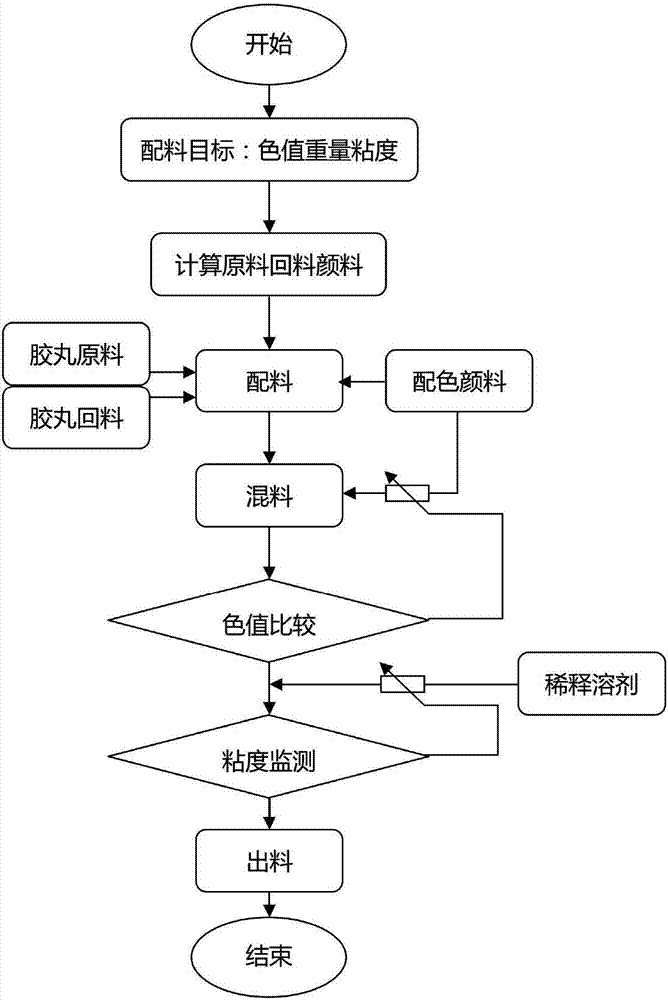

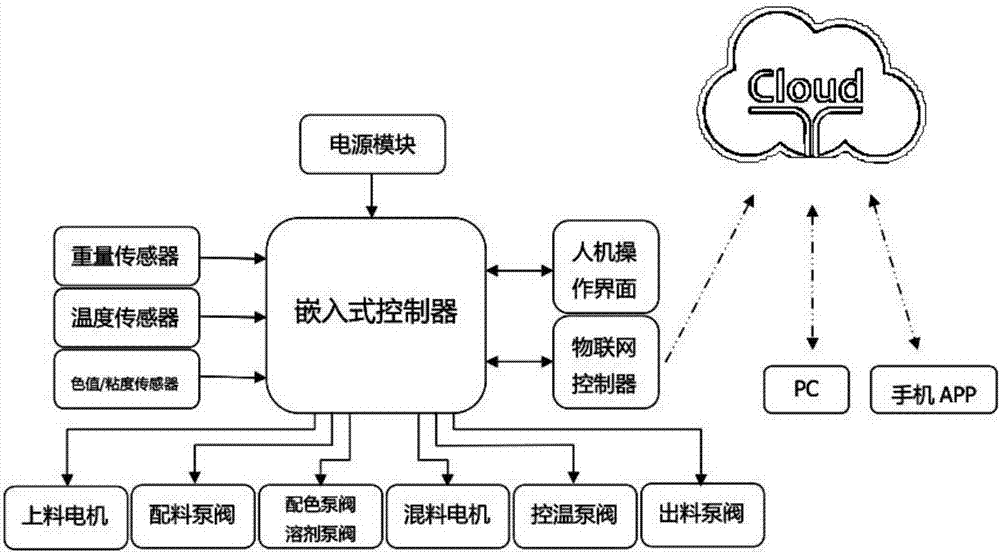

[0016] In order to solve the problems existing in the prior art, an automatic mixing and toning device for capsules is provided, which includes a frame body, a batching bucket 2 fixed above the frame body, and a color value detector 1; a mixing bucket fixed to the bottom of the frame body 8. One end extends into the mixing tank, the other end is connected to the agitator driven by the motor, the pump valve 9 and the discharge pipe 10 communicate with the lower part of the mixing tank; The feeding pipe 5; the mixing tank is provided with a thermometer 6, a viscometer 7 and a color value monitor; the batching tank and the raw and auxiliary material tank are connected to each other through the feeding pump 3 and the feeding pipe 4; the color value monitoring The controller, motor, thermometer, viscometer and pump valve are electrically connected with the control unit.

[0017] Specifically, an implementation case is provided. Such as figure 1 As shown, the batching and mixing e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com