Mini type full-automatic meat grinder

A fully automatic meat grinder technology, applied in mixers, dissolving, chemical instruments and methods, etc., can solve the problems of defective meat grinder worm design, unstable performance of the transmission mechanism, easy to leave large pieces of meat, etc., and achieve a compact structure. , Small footprint, beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

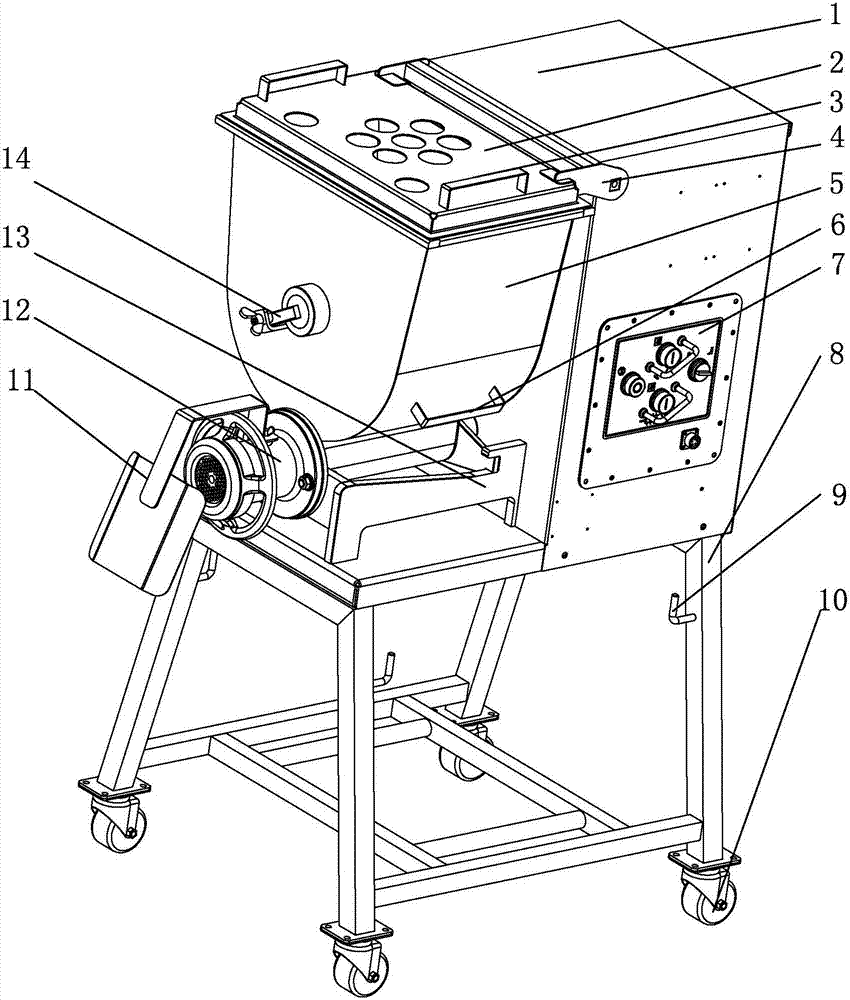

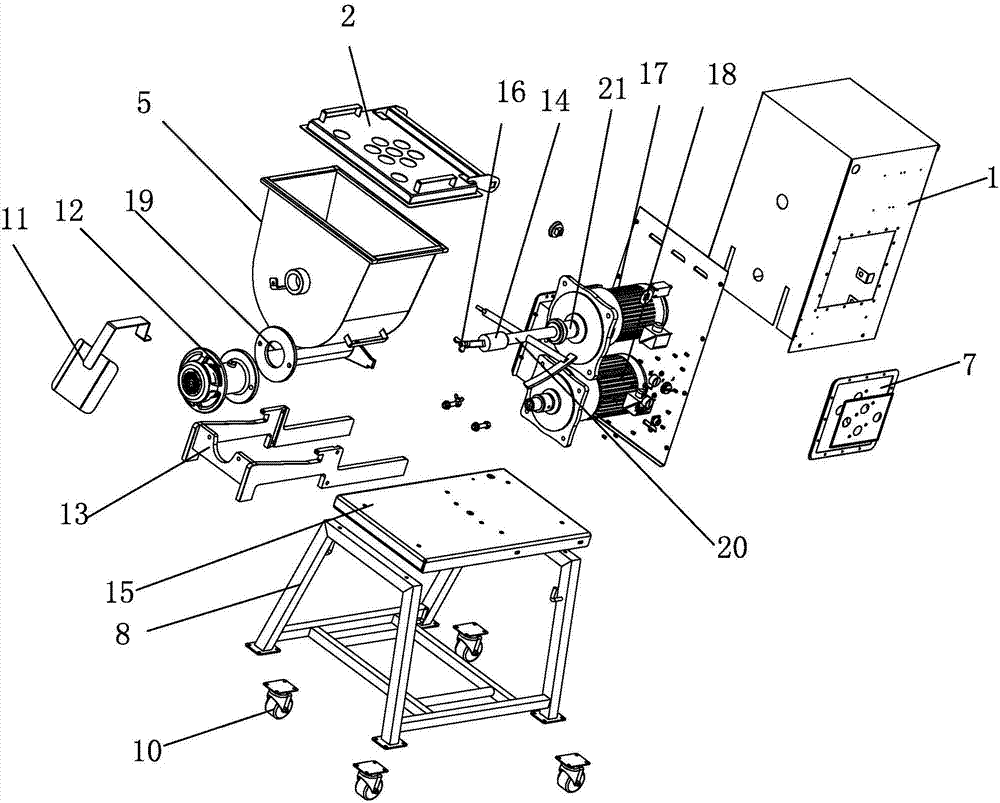

[0034] Such as figure 1 with figure 2 As shown, the miniature fully automatic meat grinder of the present embodiment includes a chassis 8, the top of the chassis 8 is an installation base 15, and one end of the installation base 15 is equipped with a fuselage guard plate 1, and the fuselage guard plate 1 The power unit is installed inside, the other end of the installation base 15 is installed with the mixing drum 5 through the fixed support frame 13, the top of the mixing drum 5 is equipped with a safety cover 2, and the safety cover 2 is hinged with the upper part of the fuselage guard plate 1 through the connecting plate 4; Stirring paddle 20 is installed in the cylinder 5, and the meat grinding system assembly 12 is installed at the bottom of the mixing cylinder 5, and the power of the stirring paddle 20 and the meat grinding system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com