A Deviation Control Method of Pressing Oil Cylinder for Hot Continuous Rolling Mill

A technology of hot continuous rolling mill and control method, which is applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., which can solve the problems of single-sidedness, inability to level the roll gap, high scrap rate, etc., and achieve the goal of improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

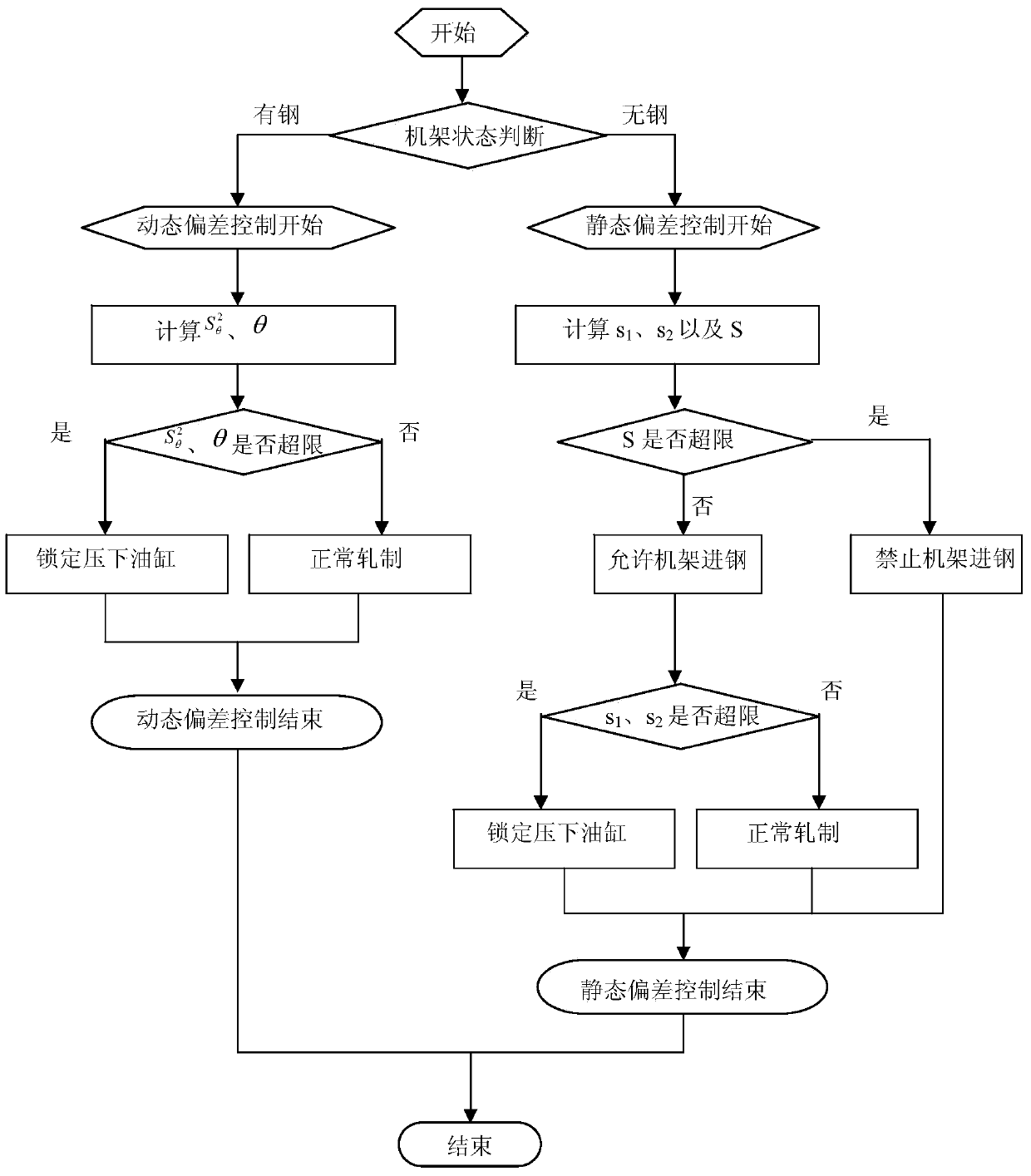

[0061] In this embodiment, the PLC system executes the program corresponding to the above-mentioned steps to control the above-mentioned execution system in the frame F1 in the above-mentioned Table 1, and the specific process is:

[0062] (1) Judgment of the frame state: at this moment, the steel strip did not arrive at the specified window (in this embodiment, the vertical roll before the finish rolling). Any value in the threshold value 400-550t has not been reached, so the frame F1 must be in the state of "no steel" at this time, and proceed to step (2b);

[0063] (2b) Static deviation control:

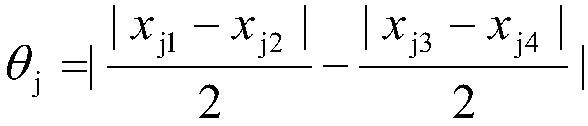

[0064] The PLC system obtains the data measured by the cylinder position sensor when the inlet end of the working side of the frame F1 is depressed at this time through the cylinder position sensor x 1 , The output end of the working side presses down the data measured by the cylinder position sensor x 2 , The data measured by the cylinder position sensor at the inlet end of the...

Embodiment 2

[0072] Summarized in this embodiment, the PLC system executes the program corresponding to the above steps to control the above-mentioned execution system in the frame F2 in the above-mentioned Table 1, and the specific process is:

[0073] (1) Judging the state of the stand: at this moment, the steel strip arrives at the designated window (in this embodiment, it is the finish rolling F1 stand), and the absolute value of the rolling force of the stand F2 is 1852t. Exceeded any value of 400-550t shown in Table 1, so the frame F2 must be in the state of "steel" at this time, and proceed to step (2a);

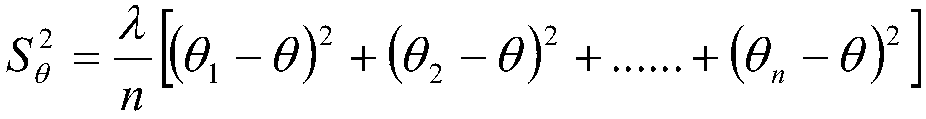

[0074] (2a) Dynamic deviation control:

[0075] The PLC system uses the cylinder position sensor to obtain the data measured by pressing the cylinder position sensor at the inlet end of the working side of the frame F2 within 20 scan periods j (j=1,2,3...20) within 1 second with a scan period of 50ms x j1 , The output end of the working side presses down the data measured by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com