A method of controlled rolling and controlled cooling for improving free-cutting steel wire rod sulfide morphology

A technology of controlled rolling and controlled cooling, steel wire rod, applied in the direction of metal rolling, temperature control, etc., can solve the problems of steel suffocation, achieve the effect of reducing quantity, reducing the accident rate of high-speed rolling mills, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1. Billet heating:

[0060] Slab composition C: 0.08%, Si: 0.02%, Mn: 1.32%, P: 0.08%, S: 0.40%, Cr: 0.10%, Ni: 0.06%, Cu: 0.02%.

[0061] The continuous casting billet with a section of 160mm*160mm is heated at a temperature of 760-945°C for 3.8 hours, wherein the heating temperature of the preheating section is 760-845°C, the heating temperature of the heating section is 930-945°C, and the heating temperature of the soaking section is 870-900°C.

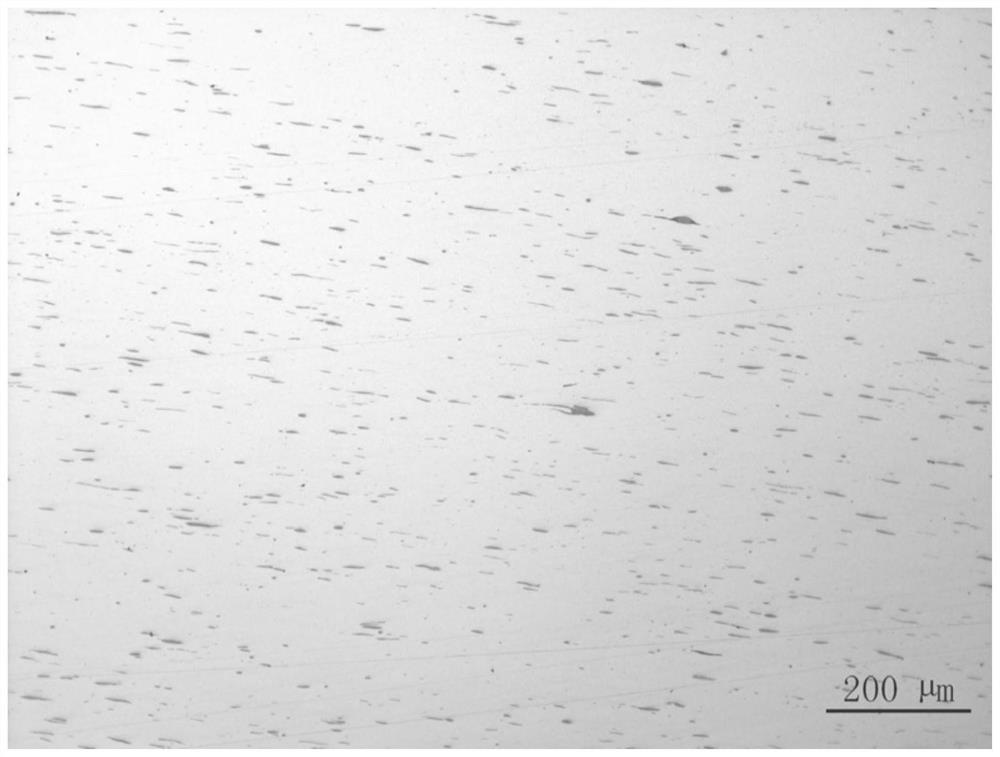

[0062] 2. Controlled rolling

[0063] The starting temperature of rough rolling is 837-850°C. The head of the rolled piece after rough rolling is heated by an online burner and then enters the middle rolling unit for rolling. The rolling temperature of the middle rolling unit is 832-841°C. After the rolling in the intermediate rolling group, the rolled pieces enter the pre-finishing rolling group for rolling, and the rolling temperature of the pre-finishing rolling group is 838-850°C. The rolled piece rolled by the pre-fin...

Embodiment 2

[0070] 1. Billet heating:

[0071] Slab composition C: 0.05%, Si: 0.07%, Mn: 1.18%, P: 0.05%, S: 0.35%, Cr: 0.07%, Ni: 0.03%, Cu: 0.03%.

[0072] The continuous casting billet with a section of 160mm*160mm is heated at 755-935°C for 3.2 hours, wherein the heating temperature of the preheating section is 761-828°C, the heating temperature of the heating section is 920-935°C, and the heating temperature of the soaking section is 860-896°C.

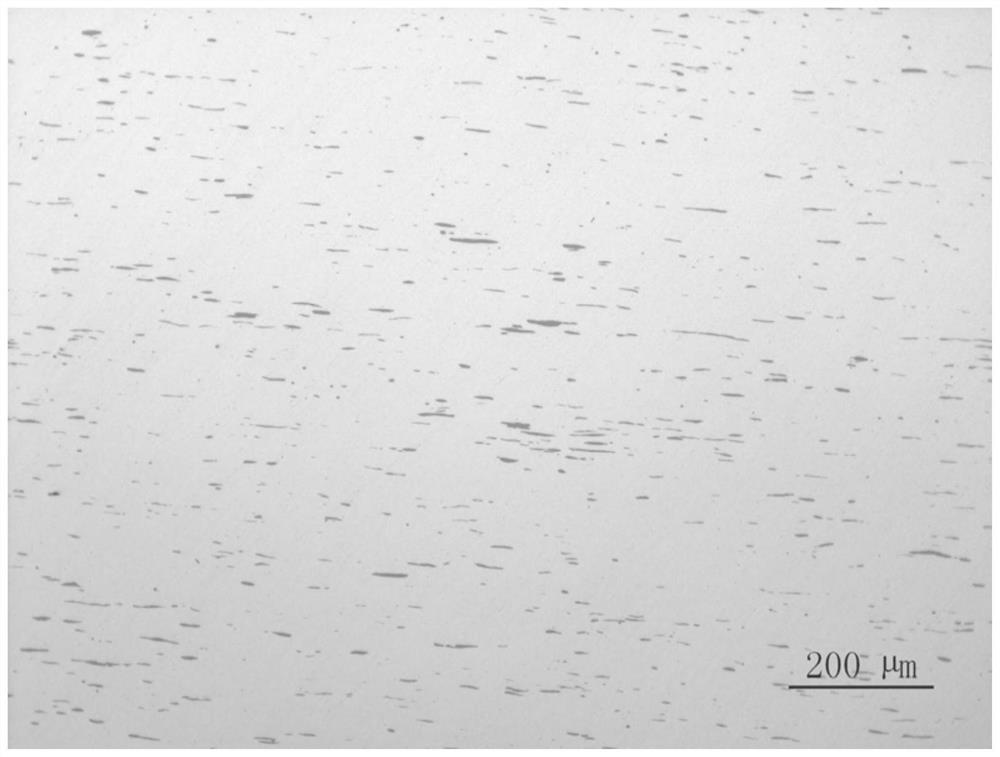

[0073] 2. Controlled rolling

[0074] The starting temperature of rough rolling is 831-841°C. The head of the rolled piece after rough rolling is heated by an online burner and then enters the middle rolling unit for rolling. The rolling temperature of the middle rolling unit is 830-839°C. After the rolling in the intermediate rolling group, the rolled pieces enter the pre-finishing rolling group for rolling, and the rolling temperature of the pre-finishing rolling group is 836-849°C. The rolled piece rolled by the pre-finishing rolling gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com