Method for reducing strip carbide width and carbide particle size of high-carbon-chromium bearing steel

A high-carbon chromium bearing steel and banded carbide technology, applied in the field of bearing steel metallurgical technology, can solve the problems of hysteresis, not comprehensively considering the impact, and not mentioning banded segregation, and achieve the effect of reducing the severity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

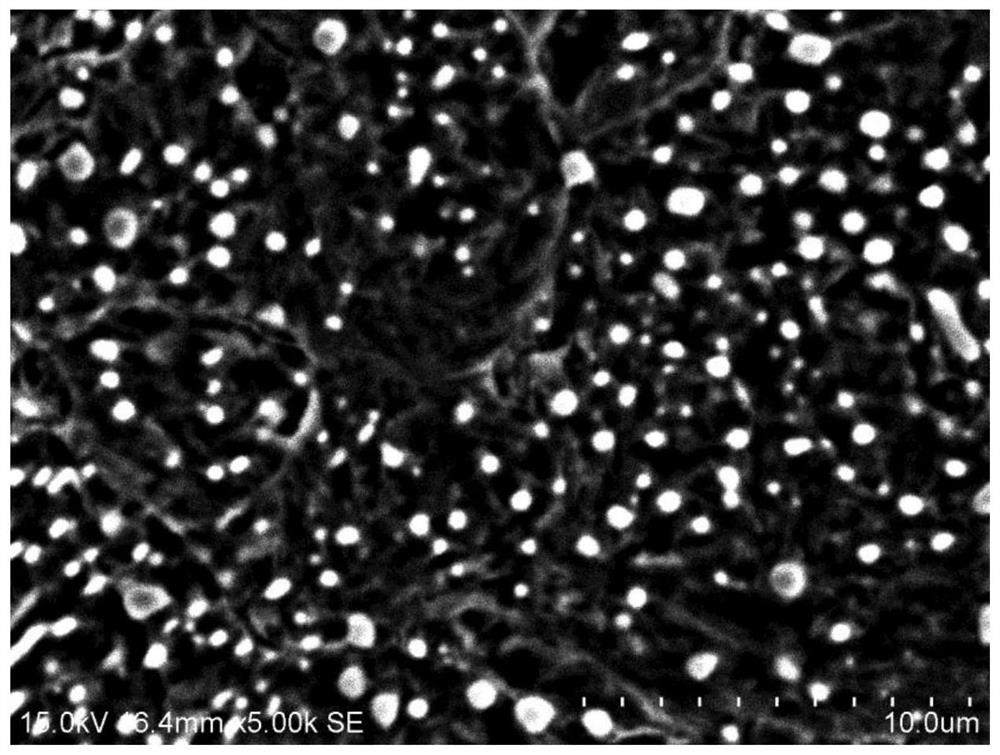

[0030] The invention provides a method for reducing the width and particle size of strip-shaped carbides in high-carbon chromium bearing steel, comprising the following steps:

[0031] (1) Continuous casting process: adopt low superheat casting, crystallizer combined with electromagnetic stirring at the end of solidification, casting speed and light reduction to match the control method to produce high-quality original slabs and reduce segregation of the original slabs;

[0032] (2) Slab grading process: carry out pickling treatment and carbon segregation detection on the original slab in step (1), and select high-quality rolling slabs according to the low-magnification rating results of slab pickling and carbon segregation index, The selection criteria for high-quality rolling billets are: billet center porosity ≤ 2.0 grade, center segregation ≤ 2.0 grade, shrinkage cavity ≤ 1.0 grade, carbon segregation index 0.95-1.05;

[0033] (3) Heating process: heating the high-quality ...

PUM

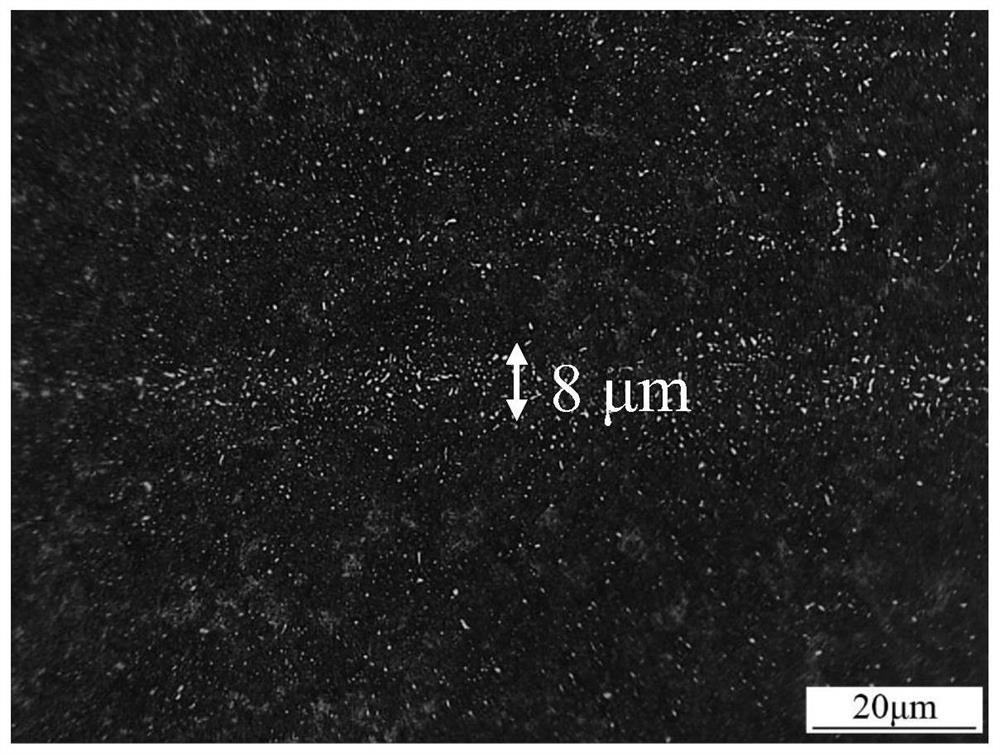

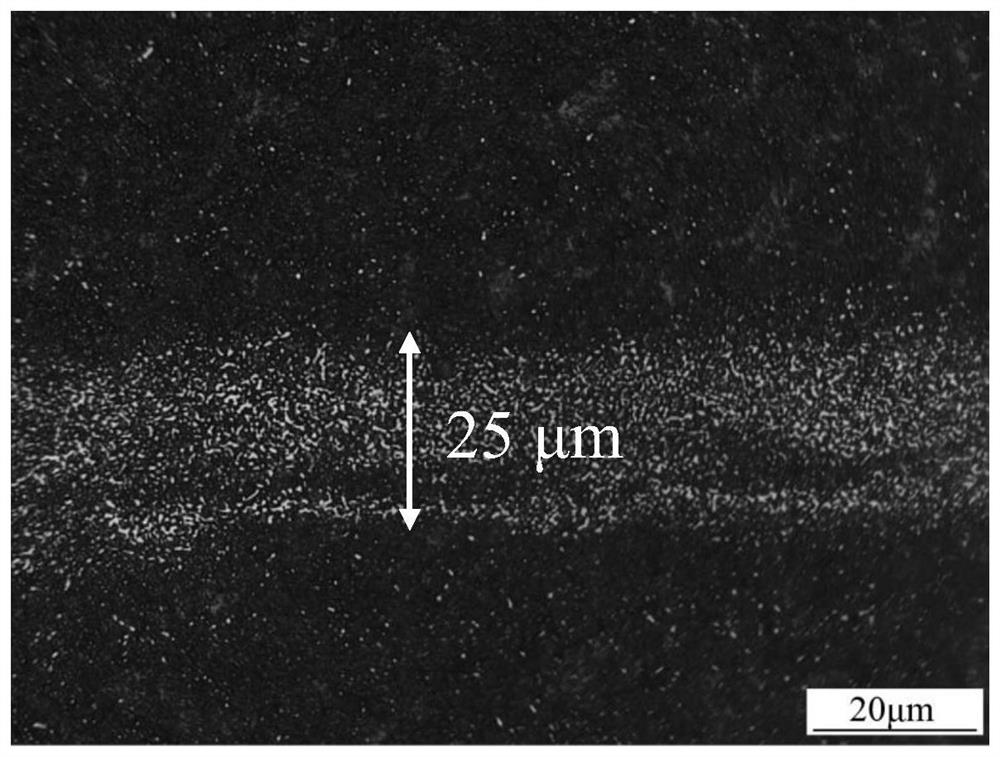

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com