Using method of high-chromium cast iron rollers

A high-chromium cast iron and roll technology, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of high-chromium cast iron rolls such as short roll period, high risk of rolling line waiting for roll, and high use cost, so as to ensure normal rolling Controlling, relieving preparation pressure and reducing roll consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

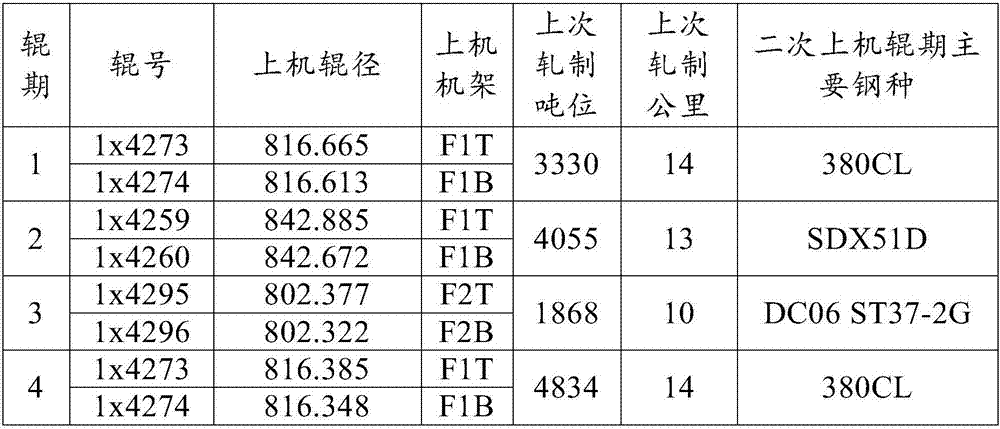

[0016] Example 1: A total of 5 rolling periods were collected and tracked. Through tracking and testing, the quality of the roll surface, the actual rolling stability, and the surface quality of the strip steel were all very satisfactory, and there were no scale defects in the roll system. In addition, the shape control Stable, no abnormality occurs, and the expected effect is achieved.

[0017]

Embodiment 2

[0018] Example 2: A total of 4 roll periods were collected and tracked. Through tracking and testing, the quality of the roll surface, the actual rolling stability and the surface quality of the strip steel were all very satisfactory, and there were no scale defects in the roll system. In addition, the shape control Stable, no abnormality occurs, and the expected effect is achieved.

[0019]

[0020] One or more technical solutions provided in the embodiments of this application have at least the following technical effects or advantages:

[0021] The method of using the high chromium cast iron roll provided in the embodiment of the present application is specifically to grade the roll surface of the high chromium cast iron roll after it is off the machine for the first time. The method reduces the grinding quantity and production cost of rolls, and eases the pressure of roll preparation; at the same time, in order to minimize the risk of strip surface quality problems, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com