Tool clamping device and tool clamping equipment

A clamping device and tooling technology, used in metal processing equipment, positioning devices, mechanical equipment, etc., can solve the problems of time-consuming and labor-intensive efficiency, and achieve the effect of improving stability and reliability, convenient operation and high clamping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

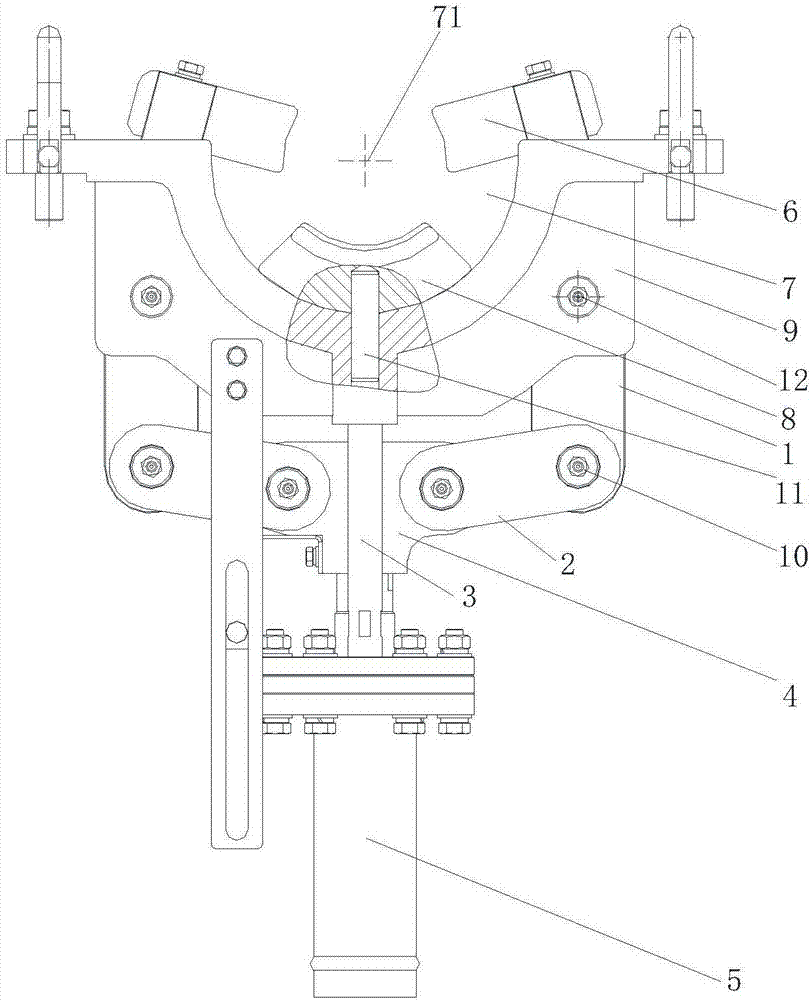

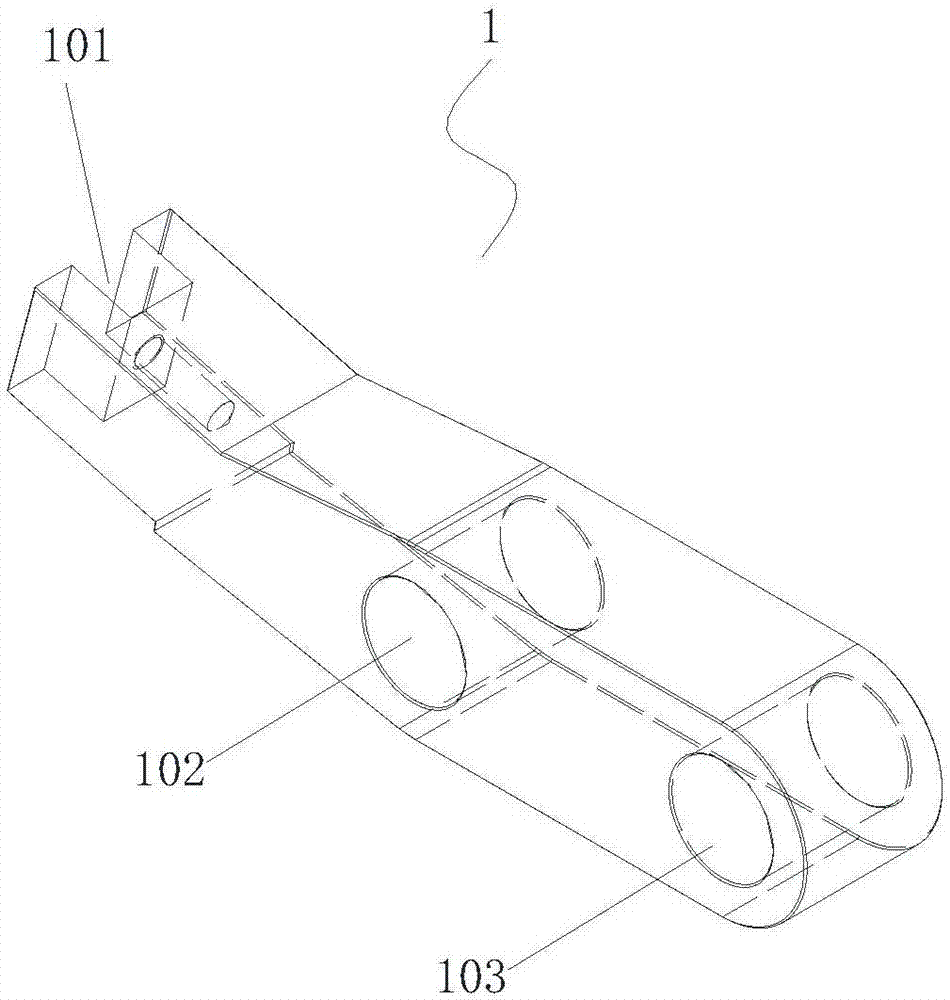

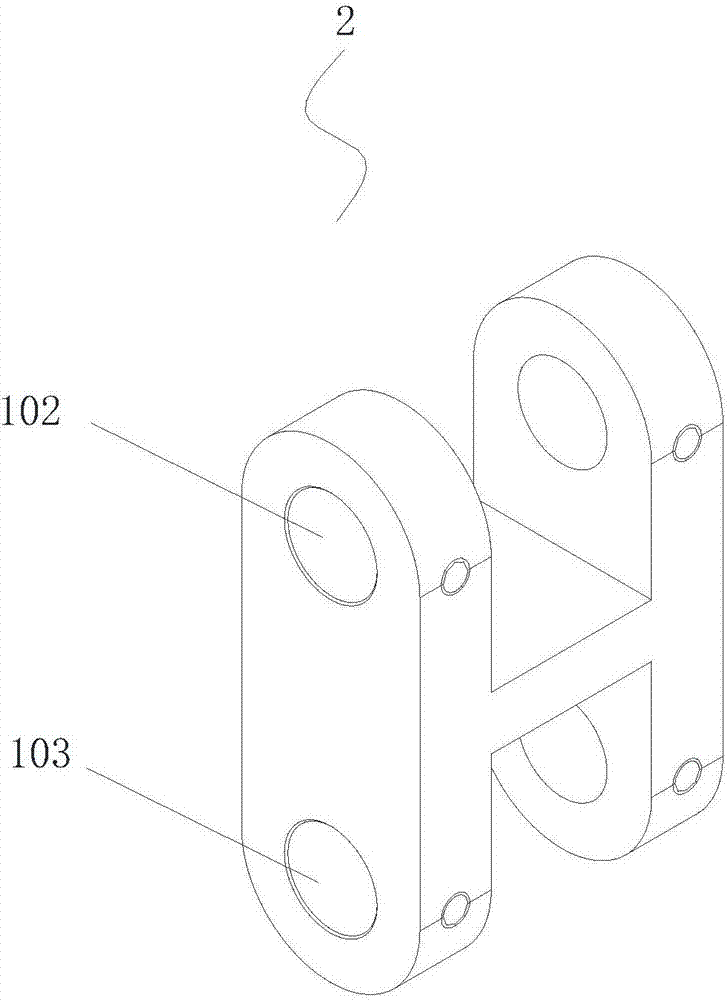

[0025] A tool clamping device, which includes a clamping seat 9 with a clamping port 7 and a power output mechanism 5 that continuously outputs stable power. The output end of the power output mechanism 5 is connected to a drive joint 4, and the power output mechanism 5 drives The driving joint 4 moves up and down, and the clamping seat 9 is connected with the clamping rod 1 through the rotating shaft 12. The height of the clamping rod 1 is greater than the height of the driving joint 4. Between the clamping rod 1 and the driving joint 4 A connecting rod 2 is provided, and the two ends of the connecting rod 2 are respectively rotatably connected to the driving joint 4 and the clamping rod 1 through the pin shaft 10. In addition, the end of the clamping rod 1 away from the connecting rod 2 and the inner wall of the clamping port 7 form a clamping Hold Space 71. The rotating shaft 12 and the pin shaft 10 are arranged in parallel, that is, the rotating direction of the clamping r...

no. 2 example

[0033]This second embodiment makes the following improvements on the basis of the first embodiment: when the drive joint 4 moves to the highest point, the drive joint 4 and the connecting rod 2 are located on the same straight line; 2 When it is on the same straight line, the drive joint 4 can no longer move up, which means that there is no need for the user to adjust the stroke of the drive joint 4, only when the drive joint 4 cannot continue to move up, the drive joint 4 has been realized. The connecting rods 2 are located on the same straight line, so that the force transmitted from the connecting rod 2 to the drive joint 4 cannot produce a torque that makes the drive joint 4 rotate, which also forms a dead point, which means that the user does not need to specially adjust the drive The size of the upward stroke of the joint 4 can form a dead point, which can make the operation more convenient and quick.

[0034] In this embodiment, when the drive joint 4 moves up to the hi...

no. 3 example

[0037] In addition, because the sizes of the workpieces are different, if the size of the workpieces is too small, when the drive joint 4 moves up to the highest position, the workpieces still cannot be fixed in time. For this problem, further optimization is carried out in this embodiment: according to figure 1 and figure 2 As shown, the end of the clamping rod 1 away from the connecting rod 2 is detachably fixed with a clamping block 6, and the inner wall of the clamping opening 7 is detachably fixed with a workpiece bracket 8, through the clamping block 6 and the workpiece bracket 8 Compressing the clamping space 71 formed by the clamping rod 1 and the clamping opening 7 realizes the clamping and fixing of smaller workpieces.

[0038] In this embodiment, the workpiece is clamped by using the workpiece bracket 8 and the clamping block 6 . Therefore, the shape of the workpiece bracket 8 and the shape of the clamping block 6 can also be replaced according to the shape of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com