Automobile cable harness shielded cable machining integrated machine and machining method thereof

A technology for automotive wiring harnesses and shielded wires, which is applied to the integrated machine for processing automotive wiring harnesses and shielded wires and its processing field, which can solve the problems of affecting sorting, winding together, and inconvenient cutting and conveying devices, and achieves the effect of easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

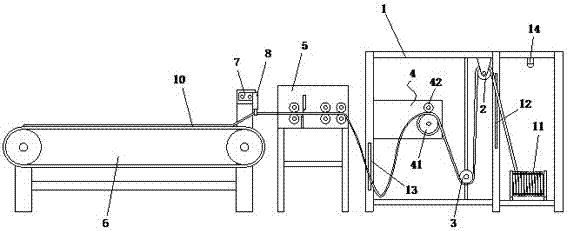

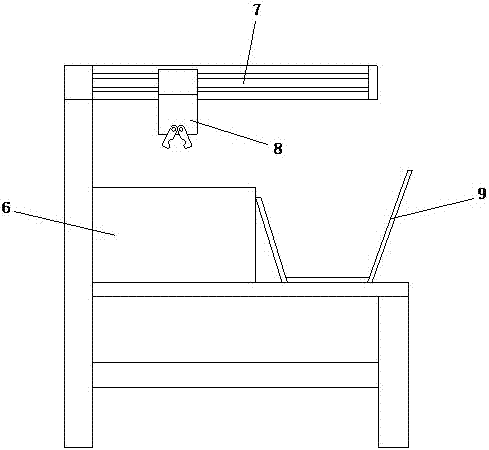

[0014] Embodiment one: if Figure 1~2 As shown, an automobile wiring harness shielded wire processing integrated machine includes an electric reel 11 arranged in sequence along the traveling direction of the cable 10, a cable conveying mechanism 4, a wire cutting machine 5, a wire throwing mechanism, and a PLC control unit for controlling the operation of the aforementioned mechanism system, the electric reel and the cable conveying mechanism are arranged on a frame 1, and the cable conveying mechanism includes a roller 41 hinged on the frame and a driving wheel 42 driven by a motor to rotate, so that the cable Through between the roller and the driving wheel, the side wall of the roller is provided with an annular groove for accommodating cables, and a vertical first grating sensor 13 is arranged between the cable conveying mechanism and the wire cutting machine, so that When the cable enters the sensing area of the first grating sensor, the PLC control system controls and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com