Automatic cleaning system for anode mud and automatic cleaning method for anode mud

An automatic cleaning and anode slime technology, applied in the field of anode slime collection and treatment systems, can solve problems such as electrolysis failure, difficult construction, equipment damage, etc., and achieve considerable benefits and high quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

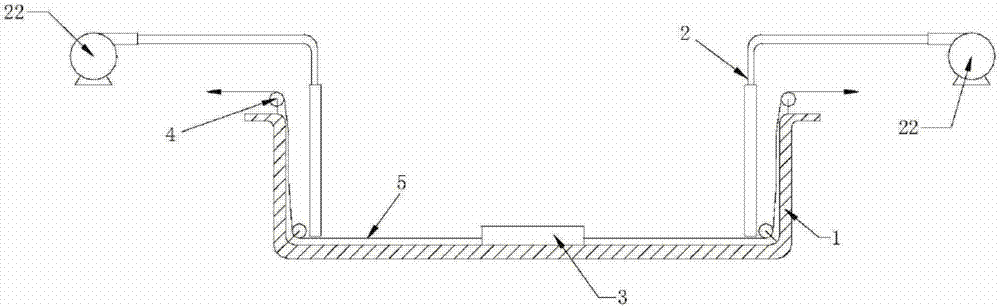

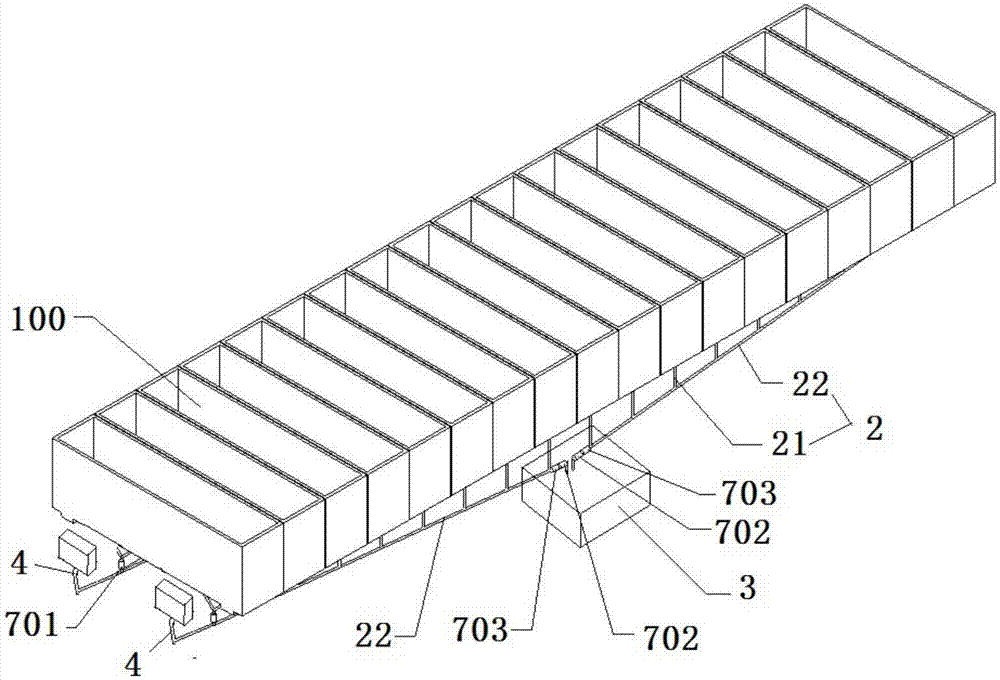

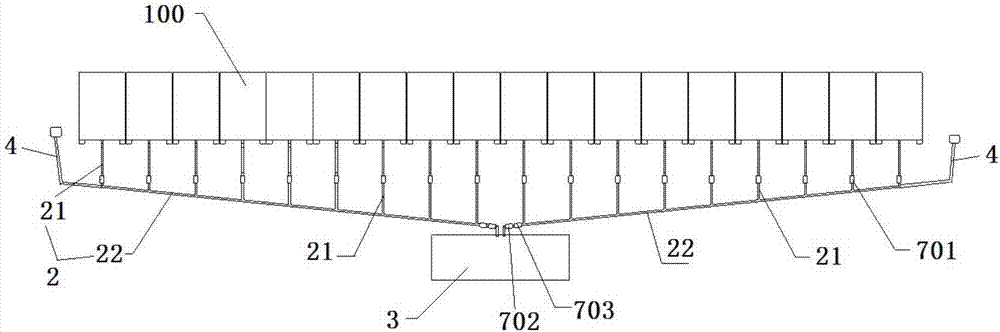

[0048] A kind of anode slime automatic cleaning system, see attached figure 2 , 3 , as shown in 4, figure 2 It is a three-dimensional schematic diagram of the anode slime collection system of the present invention, image 3 for figure 1 front view of the Figure 4 It is a schematic diagram of the bottom structure of the electrolytic cell 100 of the anode slime collection system of the present invention. The automatic anode slime cleaning system of the present invention includes a diversion funnel 1, a sludge discharge pipe 2, and a filter press 3 arranged at the bottom of the electrolytic cell 100, and the diversion funnel 1 communicates with the upper surface 101 and the lower surface 102 of the bottom of the electrolytic cell. The diversion funnel 1 has a conical structure with an inclination angle of 38-50 degrees, and the best inclination angle of the diversion funnel is 45 degrees. The diversion funnel of the conical structure includes an upper opening 11 located o...

Embodiment 2

[0052] Such as Figure 5 , figure 1 as shown, Figure 5 It is a structural schematic diagram of the electrolytic cell and the sludge discharge pipe of the automatic anode slime cleaning system of the present invention. A main pipe 22 is connected to the same row of branch pipes 21 at the bottom of a plurality of side-by-side electrolytic cells; the branch pipes are Y-shaped branch pipes, and one Y-shaped branch pipe is connected to the mud discharge ports of two diversion funnels adjacent to the bottom of the same electrolytic cell , input the anode slime in the two diversion funnels into the main pipe; preferably, one main pipe is connected with the same row of Y-shaped branch pipes at the bottom of multiple electrolytic cells arranged side by side. As a further preferred solution of this embodiment, the bifurcation angle of the Y-shaped branch pipe is not less than 45 degrees. The main pipe is horizontally inclined downward from the end to the end, and the included angle ...

Embodiment 3

[0054] As a further improvement of the present invention, the mud outlet 12 has been thoroughly studied, see Figure 6 , 7 , Figure 6 is a schematic diagram of the structure of an electrolytic cell with a lead plug, Figure 7 yes Figure 6 A partial enlargement of the . The mud outlet 12 adopts a tapered design to ensure that the anode mud does not remain. Simultaneously, the present invention thinks that the internal diameter of the mud discharge port of described diversion funnel is advisable 50-200mm, and 80mm is the best, when mud discharge port 12 is taper design, the internal diameter of said mud discharge port here refers to the mud discharge port. The smallest inner diameter on the mouth. Such an inner diameter ensures that the anode slime does not block the sludge discharge port and does not affect the normal flow of the electrolyte. Also can be equipped with lead plug 8 for described mud outlet 12. The mud discharge port is equipped with a lead plug. When the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com