Steam setting machine with manipulator

A steam setting and manipulator technology, applied in the direction of setting/stretching annular fabrics, liquid/gas/steam textile material processing, conveyor objects, etc., can solve the problems of low degree of automation, low production efficiency, and high labor costs, and achieve automation High degree, high work stability, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] The directional terms mentioned in the following embodiments, such as "horizontal, vertical, left, right", etc., are only referring to the directions of the drawings, therefore, the directional terms used are for illustration and not for limiting the practical invention.

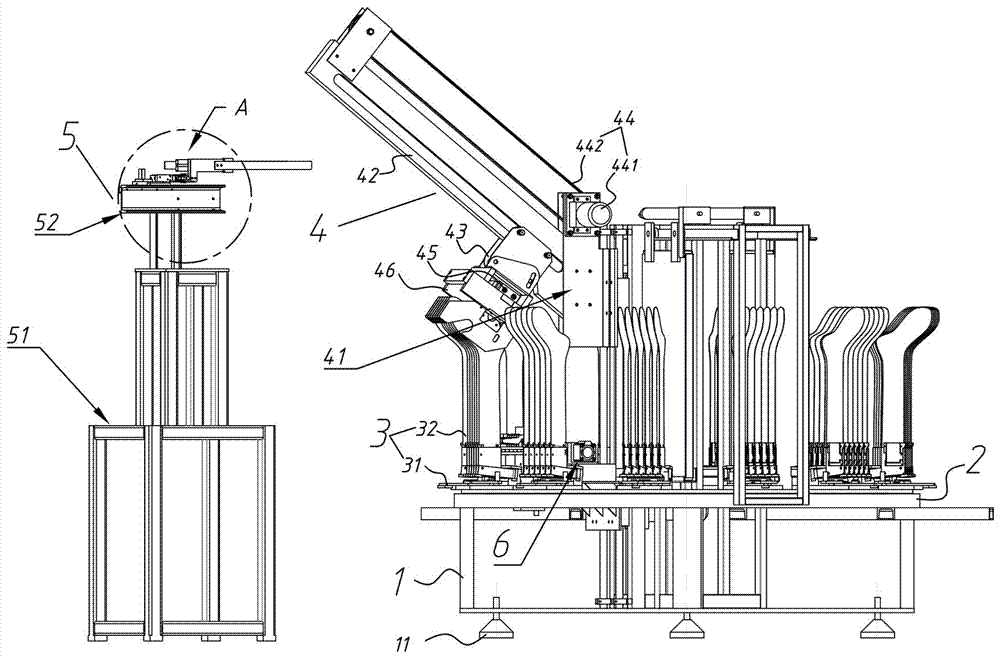

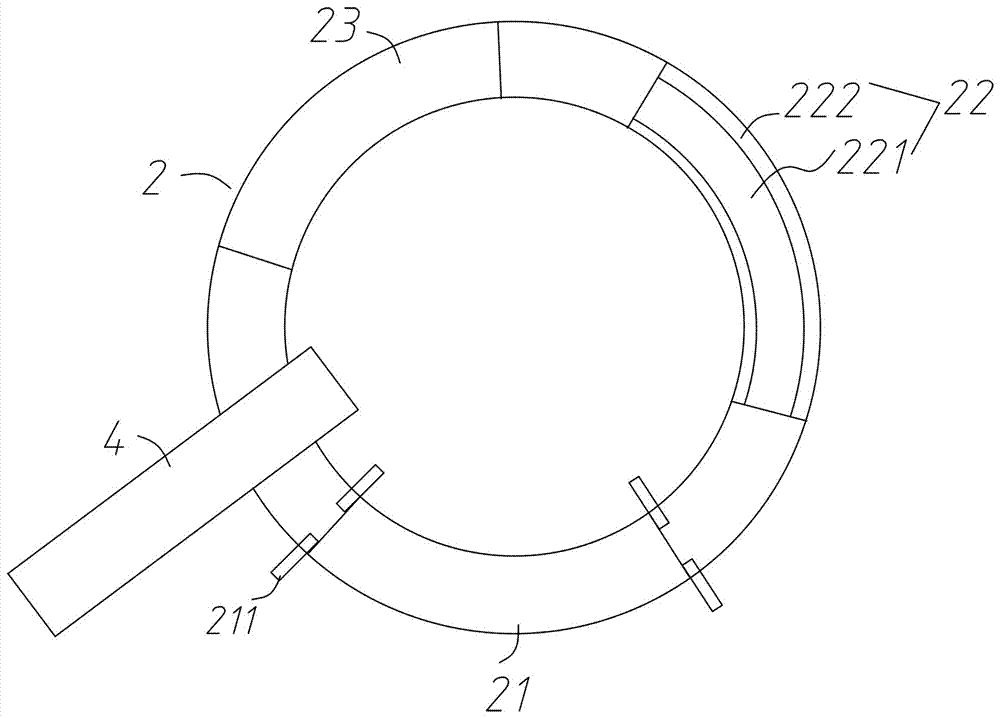

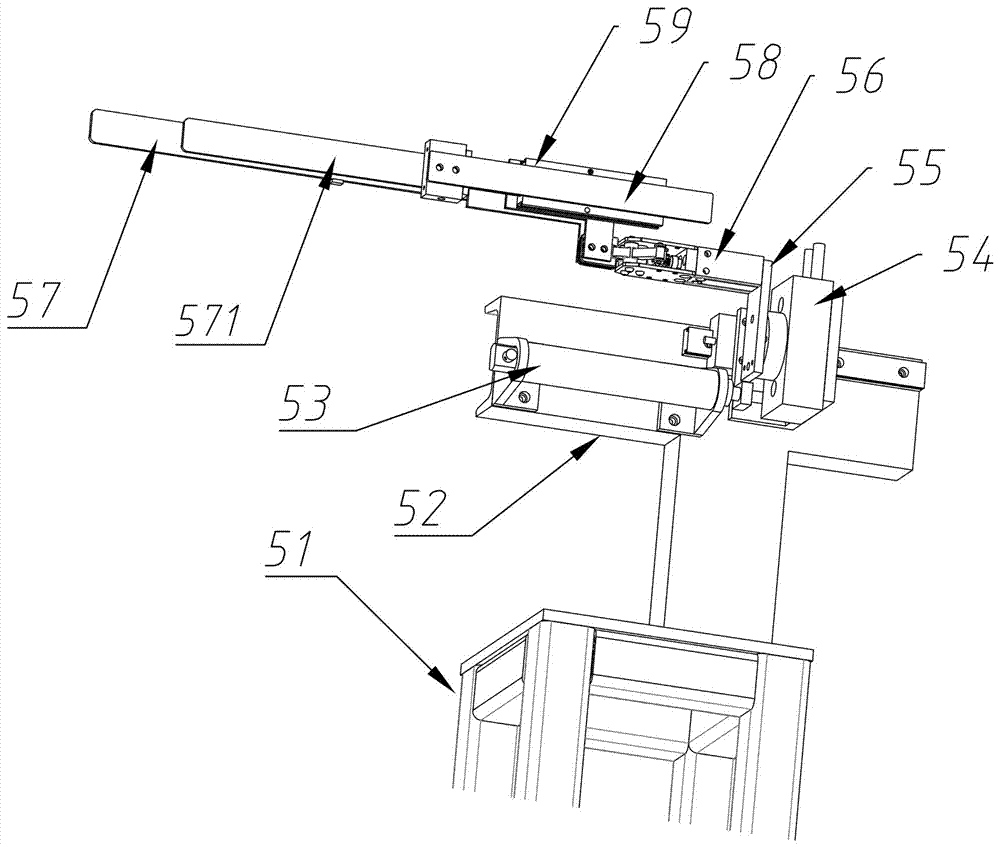

[0021] Such as figure 1 and figure 2 A steam setting machine with a manipulator is shown, including a frame 1 with a foot cup 11 at the bottom, a circular conveying track 2 installed on the frame 1, a sock plate device 3 installed on the conveying track 2, and erected in turn on the The steam setting device 21, the drying device 22, and the cooling device 23 above the conveying track 2; the sock plate device 3 includes a mounting base plate 31 erected on the conveying track 2 and several sock plates 32 vertically installed on the mounting base plate 31 The top of the steam setting device 21 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com