Organic Rankine circulation system with working medium charge volume being dynamically adjustable

A circulation system and charge technology, applied in the field of organic Rankine cycle system, can solve problems such as imperfect means and strategies, difficult implementation cost of working medium, etc., and achieve the effect of dynamic adjustment of working medium charge and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

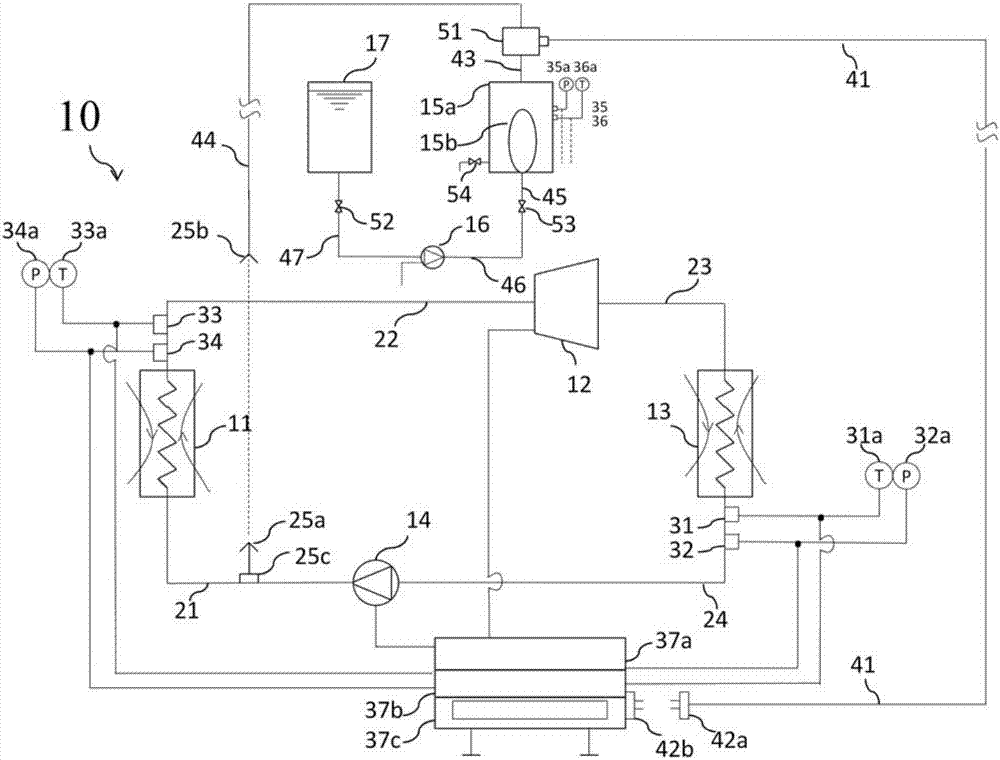

[0021] Such as figure 1 The organic Rankine cycle (ORC) system 10 shown as a dynamically adjustable working fluid charge includes an evaporator 11, an expander 12, a condenser 13, a working medium pump 14, and a high-pressure working medium pipeline 21 , 22, a closed-loop organic working medium circuit formed by low-pressure working medium pipelines 23 and 24. The liquid working medium exits the working medium pump 14, passes through the high-pressure working medium pipeline 21, and enters the evaporator 11 to fully absorb the heat of the low-temperature heat source to be vaporized. The high-temperature and high-pressure working medium steam enters the expander 12 through the high-pressure working medium pipeline 22 to expand and output mechanical work. The expanded working fluid then enters the condenser 13 through the high-pressure working medium pipeline 23 to condense, and returns to the working medium pump 14 through the high-pressure working medium pipeline 24 to comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com