Control method for turbine-based double-combustion-chamber punching combined cycle engine

A ramjet, dual-combustion chamber technology, used in combined engines, ramjets, machines/engines, etc., can solve problems such as engine failure to relay, reduce the demand for high-temperature dynamic sealing, improve engine performance, and widen the working Mach number The effect of the lower limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

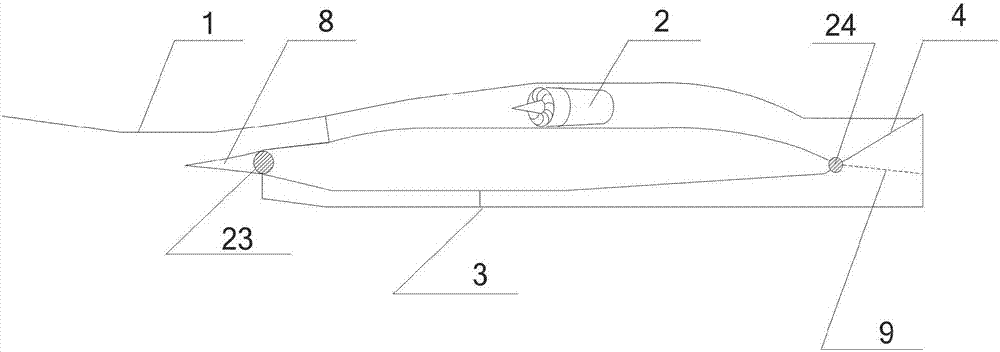

[0056] This embodiment provides a turbo-based dual combustion chamber ramming combined cycle engine. figure 1 Its cross-sectional structure is shown, and its structure includes an intake port 1, a turbine engine 2, a double-combustion chamber ramjet engine 3, and an exhaust pipe 4, wherein the turbine engine 2 is located between the intake port 1 and the exhaust pipe 4 The channel of the channel constitutes a low-speed channel, and the channel where the dual-chamber ramjet 3 is located between the intake port 1 and the tail nozzle 4 forms a high-speed channel.

[0057] The low-speed channel and the high-speed channel are connected in parallel. This parallel relationship can be parallel connection up and down, or parallel connection left and right. figure 1 It shows a parallel mode in which the low-speed channel is on the top and the high-speed channel is on the bottom.

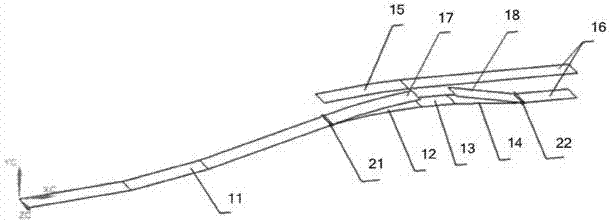

[0058] further, figure 2 A schematic diagram of the structure of a dual-combustion chamber ramjet is sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com