A Solenoid Valve Injector with Adjustable Fuel Pressure

A fuel pressure and injector technology, which is applied to fuel injection devices, machines/engines, charging systems, etc., can solve the problem of affecting fuel injection quantity and fuel injection pressure, affecting fuel injection quantity, and unable to adjust fuel injection according to specific conditions. It can prevent the fuel injection volume from being reduced and the fuel injection pressure from being low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

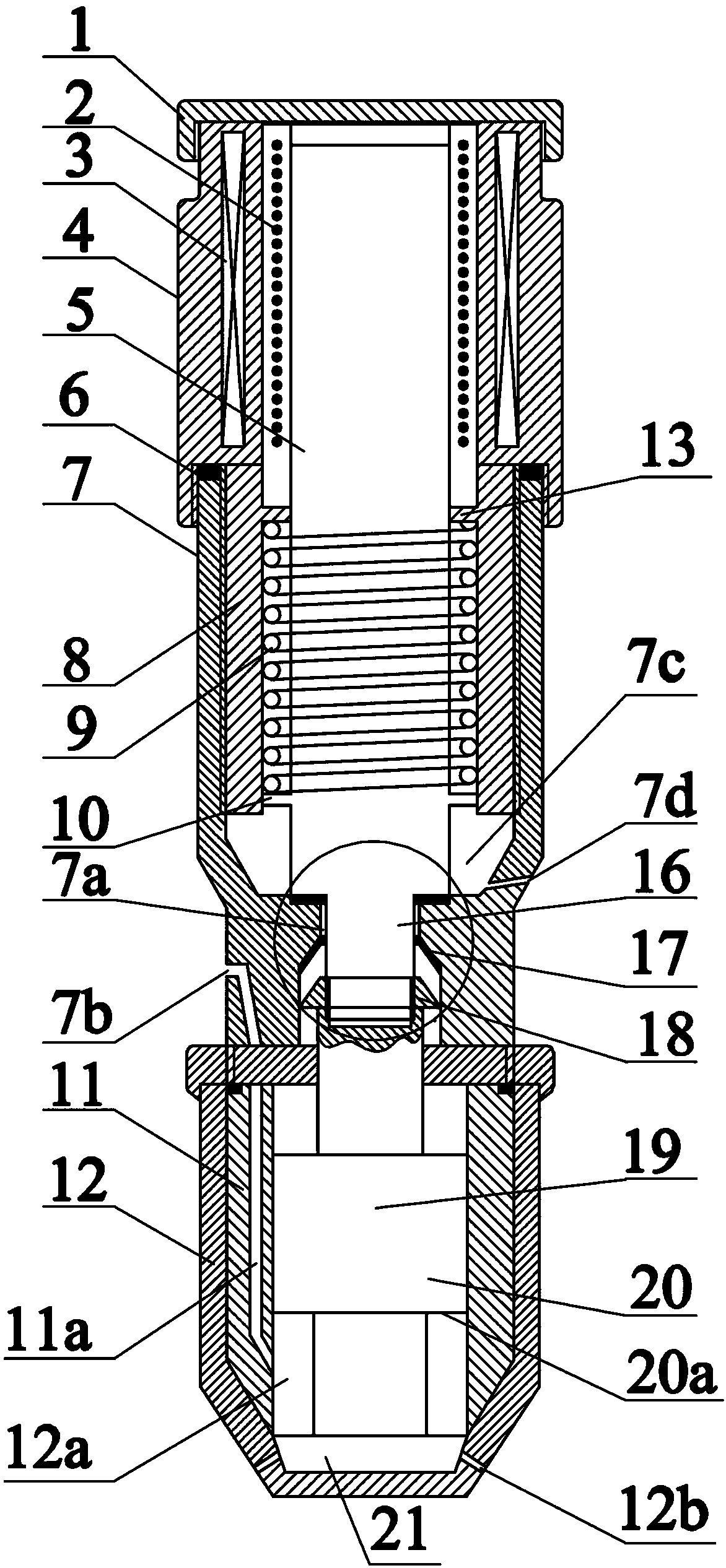

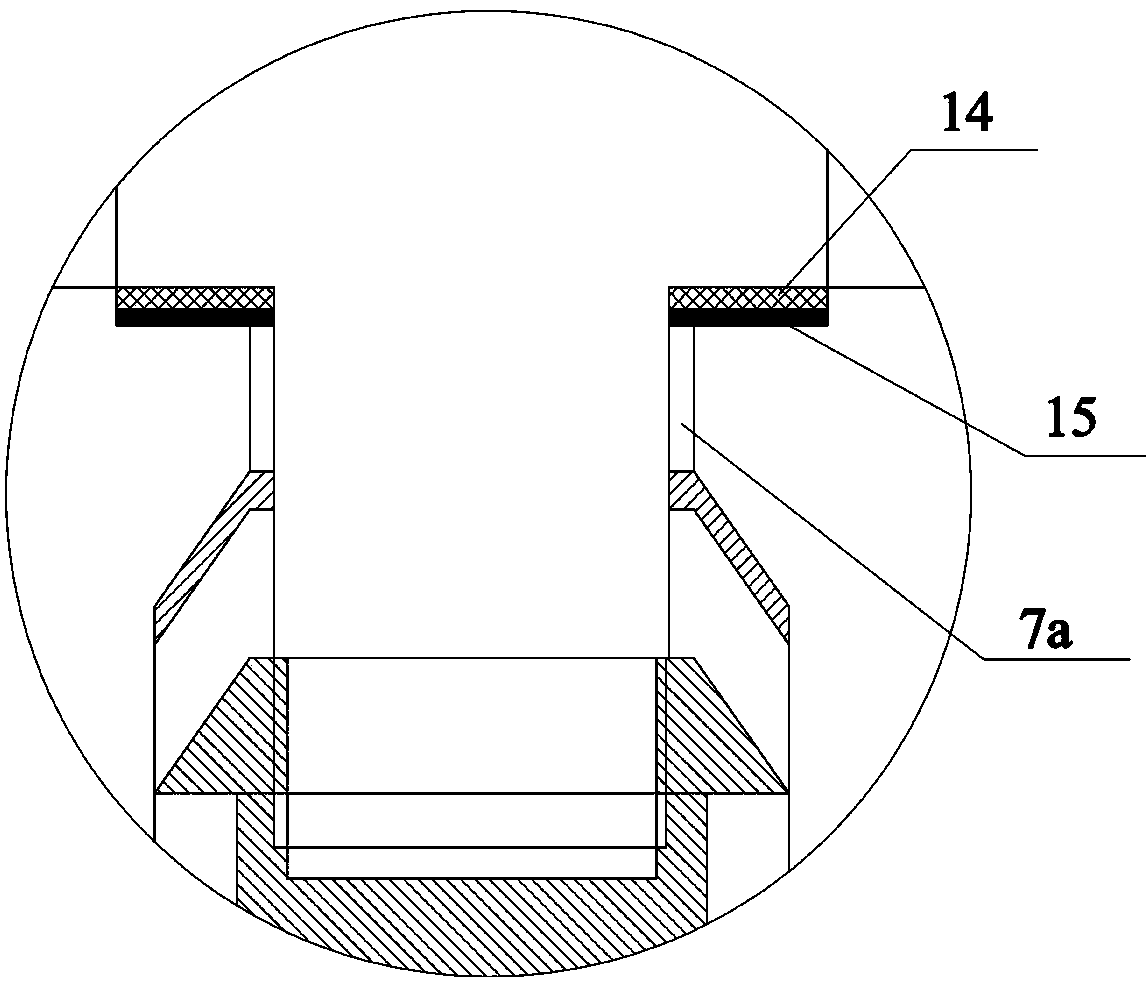

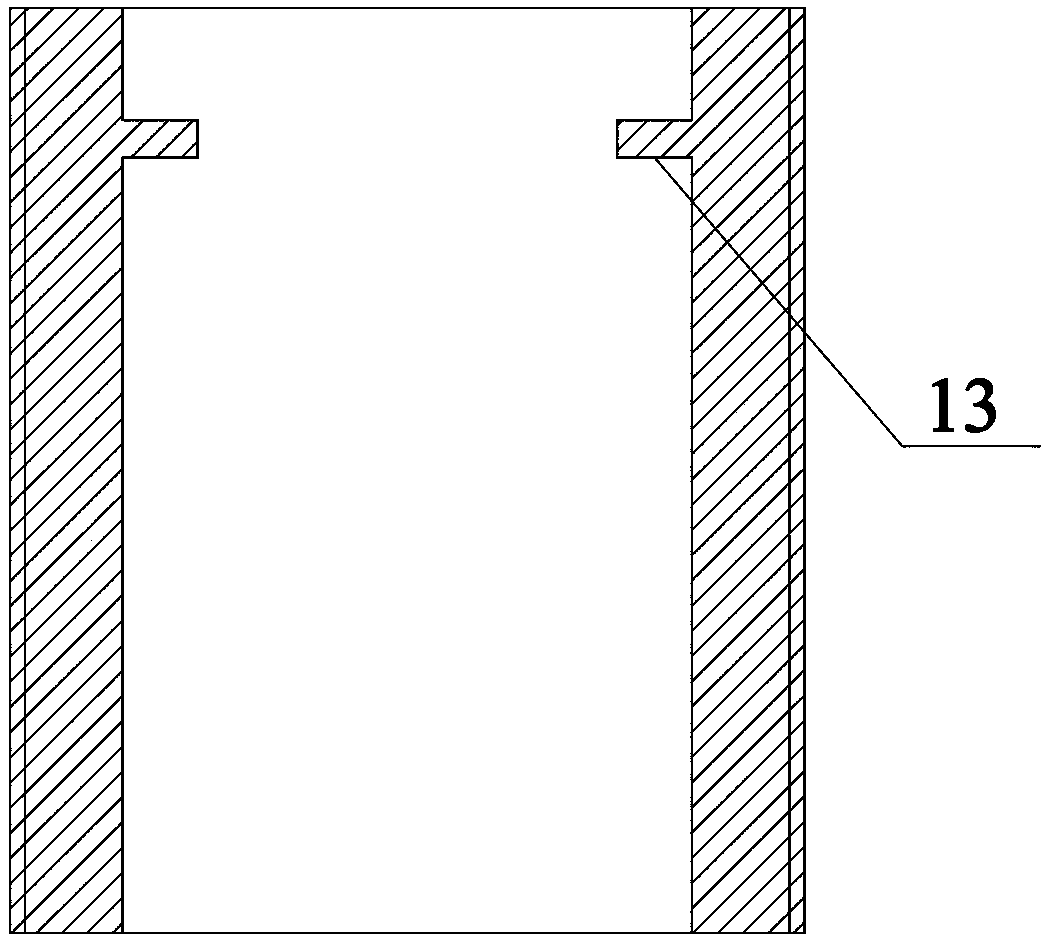

[0021] Such as Figure 1-6 As shown, the solenoid valve fuel injector with adjustable fuel pressure of the present invention includes a fuel injector top 4 , a fuel injector body 7 , and a nozzle 12 . The top end 4 of the fuel injector is sealed by the end cover 1, and the armature 5 of the electromagnetic valve installed in the top end 4 of the fuel injector is threaded with the small end cone 18 of the needle valve in the nozzle 12 through the small end 16 of the armature. Auxiliary link; the injector body 7 is threadedly connected with the valve sleeve 8, and an armature is installed between the valve sleeve protrusion 13 provided at the upper end of the valve sleeve 8 and the armature protrusion 10 provided at the lower end of the armature 5 5 return spring 9 to the original position, an oil return groove 7c is provided between the valve sleeve 8 and the injector body 7, and a pressure regulating gasket 6 is provided between the injector body 7 and the top 4 of the injecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com