Device for loosely securing desiccant cartridges at housings of air preparation equipment

A desiccant, shell technology, applied in air handling devices, gas handling, fluid pressure actuation devices, etc., can solve problems such as tightening torque fluctuations, damage to sealing elements, torsion, etc., to achieve great maintenance friendliness, avoid leakage and glitch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The same elements are denoted by the same reference numerals in all figures.

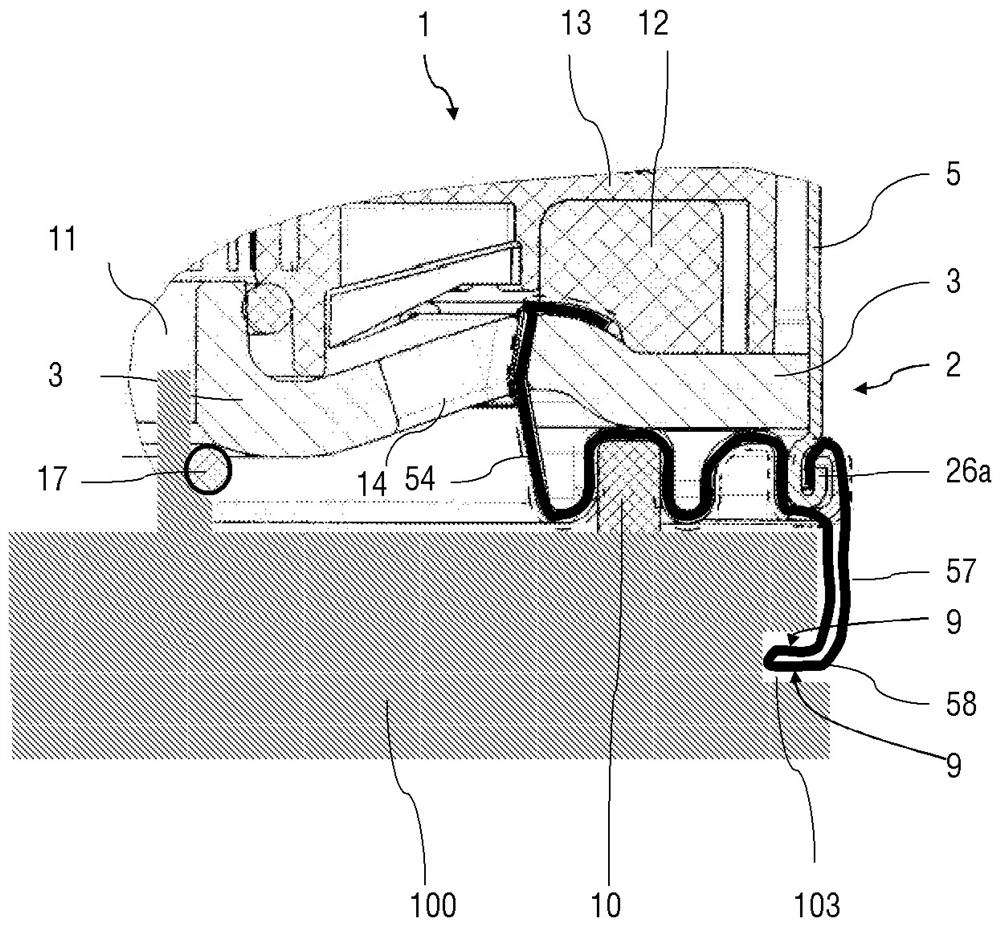

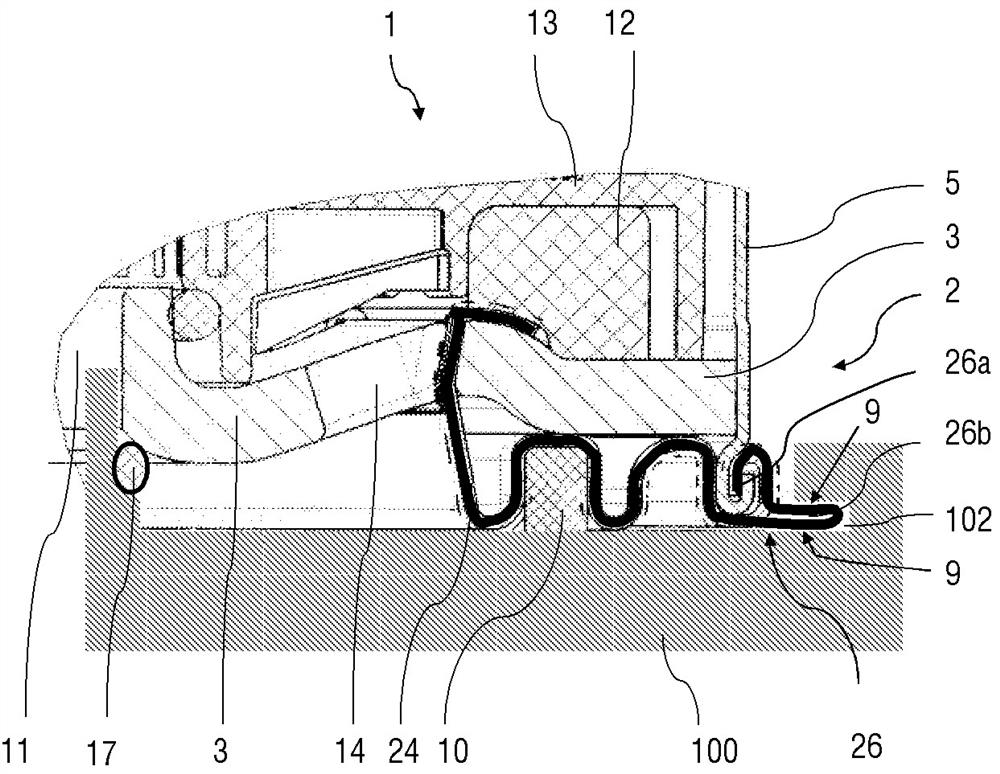

[0031] figure 1 A detailed view of a section of a desiccant cartridge according to an exemplary embodiment of the invention is shown here. figure 1 In particular, a section of the radially outer lower region of the desiccant cartridge 1 is shown. The interior of the desiccant cartridge 1 can be constructed in a manner known per se, for example as described in the laid-open documents DE 10 2013 103 066 A1, DE 10 2012 105 137 A1 and DE 10 2007 034 435 A1. For example, the reference numeral 12 designates an oil filter formed by a fleece and the reference numeral 13 designates an inner container for a desiccant, of which only a small part can be seen. figure 1 The vertical arrows in indicate the axial direction of the desiccant cylinder, and the horizontal arrows indicate the radial direction of the desiccant cylinder.

[0032] The cartridge housing of the desiccant cartridge has, in a manner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com