Sorting trolley convenient and fast to use

A convenient and rack-based technology, applied in the field of sorting equipment in the logistics industry, can solve the problems of inconvenient picking operations, scattered and stacked goods, and low efficiency, and achieve convenient access, reasonable goods placement, and convenient heavy goods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

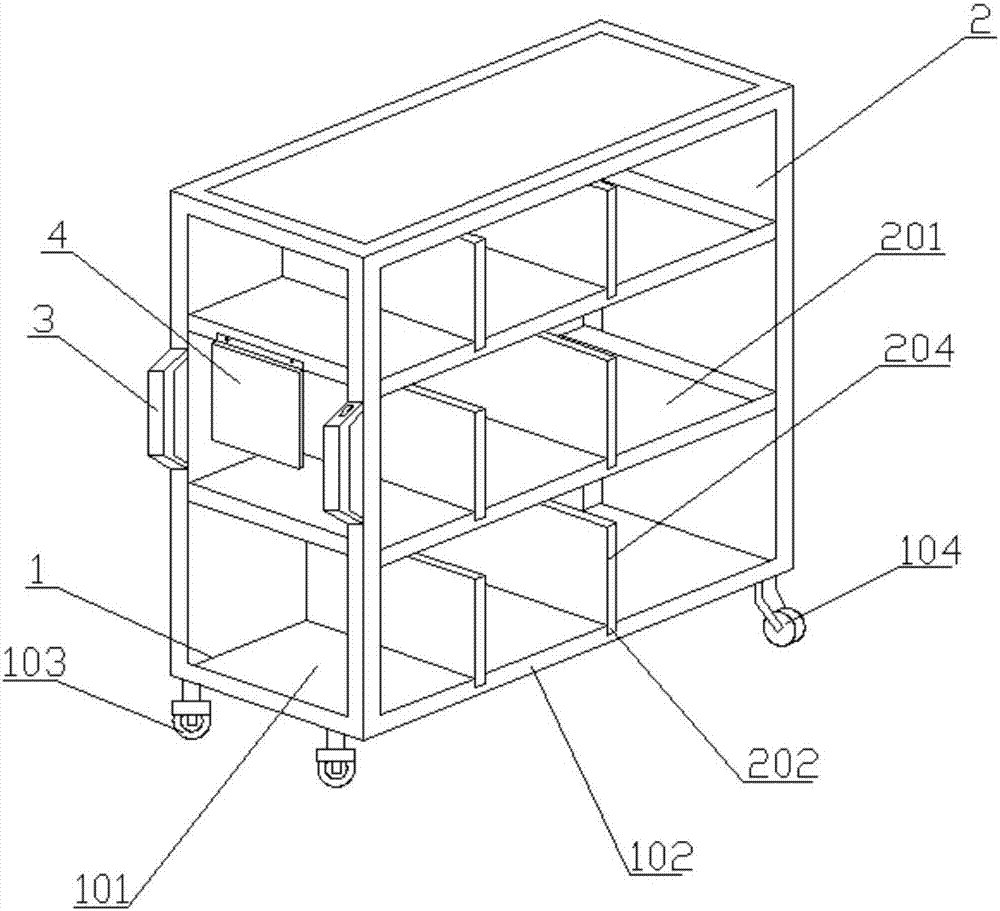

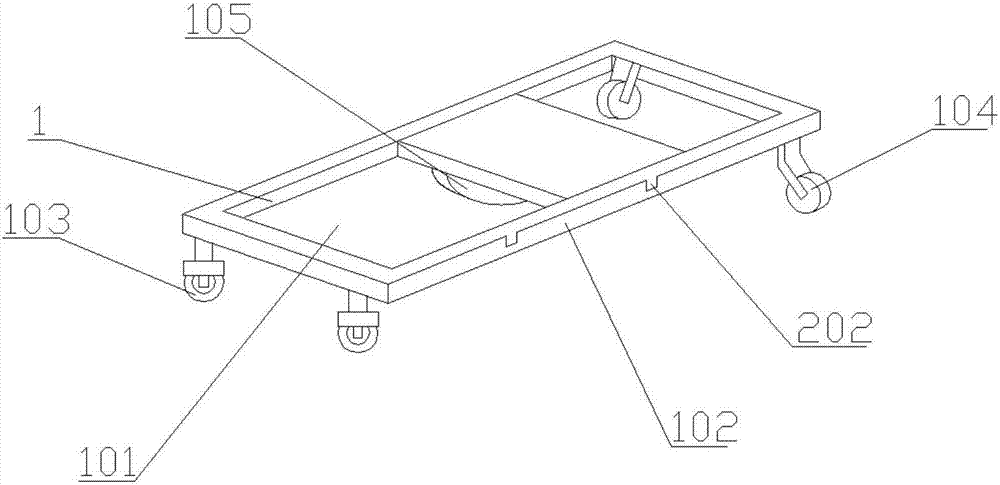

[0032] Such as figure 1 and image 3 As shown, a convenient sorting vehicle includes a vehicle frame 1, a walking part and a shelf. The vehicle frame 1 includes a bottom plate 101 and a square frame 102 arranged around the bottom plate 101. The front end of the square frame 102 is provided with universal wheels 104, square The rear end of frame 102 is provided with directional wheel 103, and the bottom of base plate 101 is provided with driving wheel 105, and driving wheel 105 is connected with power drive device, and power drive device adopts motor, and the output shaft of motor is connected with the axle of drive wheel 105. The frame 1 is spliced by the bottom plate 101 and the square frame 102. The directional wheels 103, the universal wheels 104 and the driving wheels 105 are installed on the bottom of the frame 1 in a modular manner. The universal wheels plus the directional and driving wheels are used to control the vehicle body. offset.

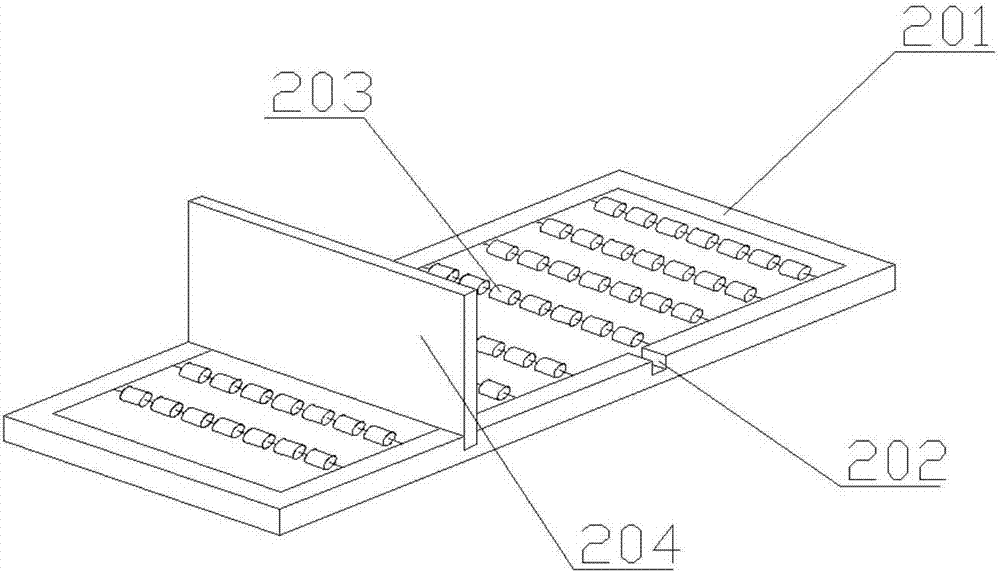

[0033] Such as figure 2 A...

Embodiment 2

[0037] Such as Figure 4 As shown, the auxiliary device for storing and withdrawing goods in this embodiment can also adopt other methods, such as adopting a conveyor belt 205 arranged on the floor plate 201, and the conveyor belt 205 includes two layers of belts that rotate in circles up and down. The upper and lower belts rotate circularly on the shelf, and the goods are stored on the upper belt. When picking up and placing heavy goods, relying on the transmission of the belt is convenient for picking and placing heavy goods. The goods can be easily pushed on the shelf, which is convenient for heavy goods to be picked up. put.

Embodiment 3

[0039] Such as Figure 5 , Figure 6 and Figure 7 As shown, the difference between this embodiment and the above-mentioned embodiments is that a pedal 5 is also provided at the rear end of the vehicle frame 1, the pedal 5 is hingedly connected with the rear end of the vehicle frame 1, and a rear end of the vehicle frame 1 extends The pedal support plate 6 is used to support the pedal 5 . Pedal 5 can be folded and stuck on the vehicle body, and can also be rotated along the hinged shaft. The width is consistent, and the width of the pedal 5 is about 25 cm. The pedal 5 can carry the weight of a person. The picker can stand on the pedal 5 with both feet and move with the car.

[0040] The power drive device in the above embodiments can be replaced by not only a motor, but also a hydraulic motor, an air motor, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com