Activated carbon for water purification

A technology for activated carbon and water purification, applied in the field of activated carbon for water purification, can solve the problems of low yield of activated carbon products and high production cost, and achieve the effects of low cost, good mechanical strength and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

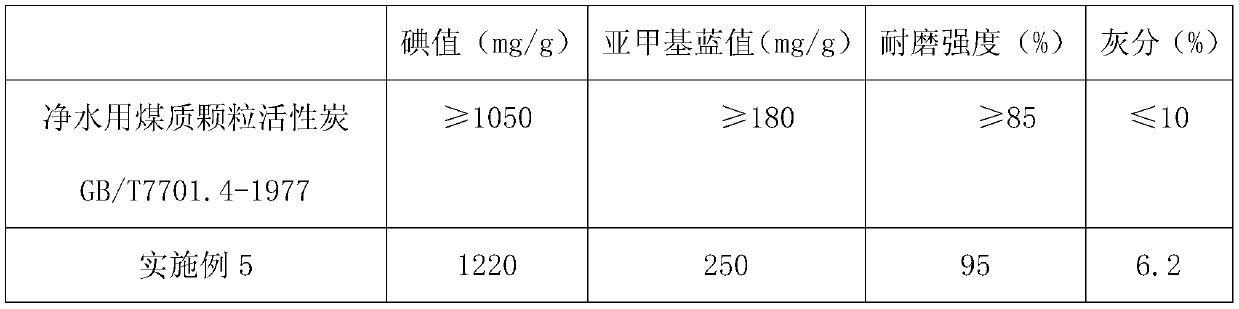

Examples

Embodiment 1

[0021] In the embodiment of the present invention, activated carbon for water purification is made through the following steps:

[0022] 1) After the straw is dried, it is crushed and sieved to 10 mesh, and mixed evenly; it is preliminarily carbonized in a microwave pyrolysis reactor to obtain a pretreated material; the microwave power is 1000W, and the initial carbonization time is 3 minutes.

[0023] 2) Soak the pretreatment material in 15wt.% hydrochloric acid solution for 3 hours, the soaking temperature is 45°C, stir while soaking, the stirring speed is 150r / min; the mass ratio of pretreatment material to 15wt.% hydrochloric acid solution is 1:2 . Then soak in 15wt.% sodium hydroxide solution for 1h, soaking temperature is 75°C, stir while soaking, stirring speed is 150r / min; the mass ratio of pretreatment material and 15wt.% sodium hydroxide solution is 1:2 . Wash with deionized water repeatedly until neutral, and dry at 90°C to obtain a semi-finished product.

[0024...

Embodiment 2

[0026] In the embodiment of the present invention, activated carbon for water purification is made through the following steps:

[0027] 1) After the straw is dried, it is crushed and sieved to 60 mesh, and mixed evenly; it is preliminarily carbonized in a microwave pyrolysis reactor to obtain a pretreated material; the microwave power is 1500W, and the initial carbonization time is 15 minutes.

[0028] 2) Soak the pretreatment material in 35wt.% hydrochloric acid solution for 20h, the soaking temperature is 60°C, stir while soaking, the stirring speed is 300r / min; the mass ratio of pretreatment material to 35wt.% hydrochloric acid solution is 1:3 . Then soak in 30wt.% sodium hydroxide solution for 5h, the soaking temperature is 100°C, stir while soaking, the stirring speed is 300r / min; the mass ratio of pretreatment material and 30wt.% sodium hydroxide solution is 1:4 . Wash with deionized water repeatedly until neutral, and dry at 100°C to obtain a semi-finished product. ...

Embodiment 3

[0031] In the embodiment of the present invention, activated carbon for water purification is made through the following steps:

[0032] 1) After the straw is dried, it is crushed and sieved to 20 mesh, and mixed evenly; it is preliminarily carbonized in a microwave pyrolysis reactor to obtain a pretreated material; the microwave power is 1200W, and the initial carbonization time is 5 minutes.

[0033] 2) Soak the pretreatment material in 20wt.% hydrochloric acid solution for 5 hours, the soaking temperature is 50°C, stir while soaking, the stirring speed is 200r / min; the mass ratio of pretreatment material to 20wt.% hydrochloric acid solution is 1:2.3 . Then soak in 20wt.% sodium hydroxide solution for 2h, the soaking temperature is 80°C, stir while soaking, the stirring speed is 200r / min; the mass ratio of pretreatment material and 20wt.% sodium hydroxide solution is 1:2.5 . Wash with deionized water repeatedly until neutral, and dry at 95°C to obtain a semi-finished produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com