Purification and activation method of secondary and tertiary diatomite for preparing diatom ooze

An activation method and diatomite technology, applied in the directions of silicon oxide, silicon dioxide, etc., to achieve the effect of increasing adsorption effect, reducing emission and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

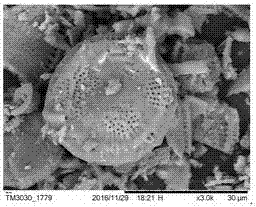

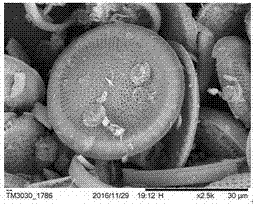

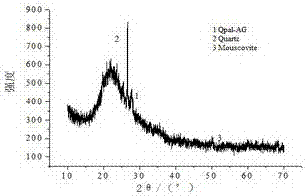

Image

Examples

Embodiment 1

[0017] 1) Grind the raw diatomite ore of the second and third grades for 15 minutes, and set the speed of the ball mill to 200r / min to obtain 250-mesh powdered diatomite;

[0018] 2) Take 100 grams of powdered diatomaceous earth from step 1) and add water to disperse according to solid: liquid = 1:3, then add 0.8L of 60% concentrated sulfuric acid, put it into a constant temperature 60°C reaction kettle and stir at a constant speed, the stirring rate is 300r / min, stirring time is 1h, washed with water to neutral PH=7, filtered the washed diatomaceous earth, put it in an oven at 80°C for 6 hours, and cooled to room temperature to obtain pickled diatoms earth;

[0019] 3) Put the pickled diatomite in step 2) in a high-temperature furnace, pump the furnace into an anaerobic state, and then fill it with equal-pressure nitrogen protection, set the initial temperature to 50°C, and the heating rate to 5°C / min, the anaerobic heat activation temperature is 600°C, and the anaerobic h...

Embodiment 2

[0021] This embodiment is prepared by the commonly used aerobic thermal activation method

[0022] 1) Grind the raw diatomite ore of the second and third grades for 15 minutes, and set the speed of the ball mill to 200r / min to obtain 250-mesh powdered diatomite;

[0023] 2) Take 80 grams of powdered diatomite from step 1) and add water to disperse according to solid: liquid = 1:3, then add 0.64L of 60% concentrated sulfuric acid, put it into a constant temperature 60°C reactor and stir at a constant speed at a rate of 300r / min, stirring time is 1h, washed with water to neutral PH=7, filtered the washed diatomaceous earth, put it in an oven at 80°C for 6 hours, and cooled to room temperature to obtain pickled diatoms earth;

[0024] 3) Put the pickled diatomite in step 2) in a high-temperature furnace for aerobic heat activation treatment, set the initial temperature to 50°C, the heating rate is 5°C / min, and the aerobic heat activation temperature is 600°C. The aerobic therm...

Embodiment 3

[0026] 1) First, grind the secondary and tertiary diatomite raw ore machine for 10 minutes, and adjust the speed of the ball mill to 200r / min to obtain 250 mesh powdery diatomite;

[0027] 2) Take 200 grams of powdered diatomite from step 1) and add water to disperse according to solid: liquid = 1:2.5, then add 1.5L of 50% concentrated sulfuric acid, put it into a constant temperature 60°C reaction kettle and stir at a constant speed, the stirring rate is 300r / min, stirring time is 2h, washed with water to neutral PH=7, filtered the washed diatomaceous earth, put it in an oven at 80°C for 6h, cooled to room temperature, and obtained pickled diatom earth;

[0028] 3) Put the pickled diatomite in step 2) in a high-temperature furnace, pump the furnace into an anaerobic state, and then fill it with equal-pressure nitrogen protection, set the initial temperature to 50°C, and the heating rate to 5°C / min, the anaerobic heat activation temperature is 400°C, and the anaerobic heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com