Embryo culture unit and manufacturing method thereof

A technology of embryo culture and culture unit, which is applied in the direction of sterilization methods, biochemical equipment and methods, tissue cell/virus culture devices, etc., can solve the problems of embryo damage, embryo damage, death, etc., to reduce the amount of use, Effects of reducing work intensity and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

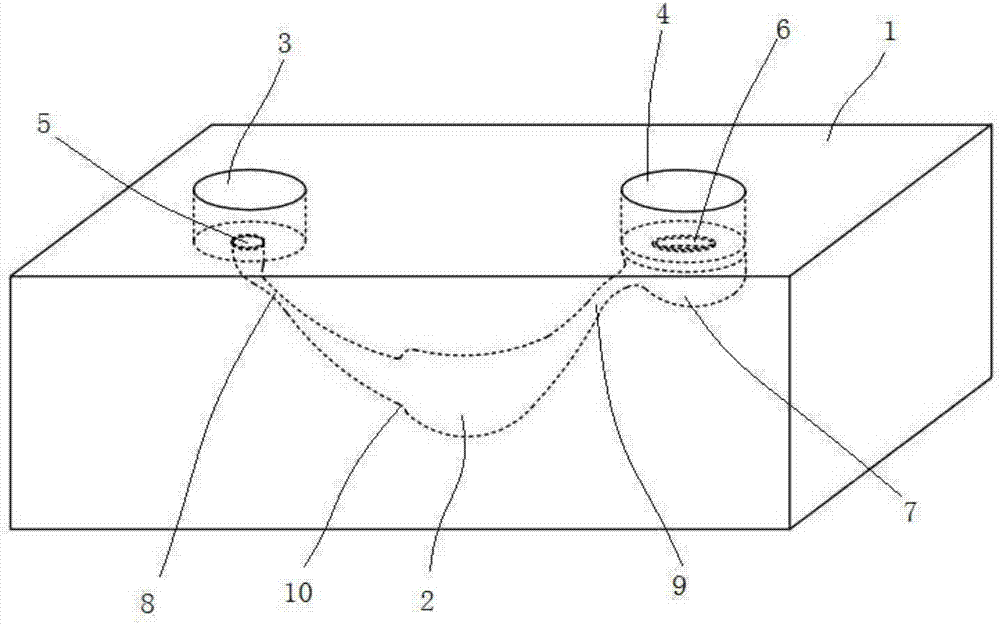

[0025] refer to figure 1 , an embryo culture unit, comprising a culture unit main body 1 of transparent material, an inlet plug hole 3 and a sampling end plug hole 4 are provided on the upper surface of the culture unit body 1, the inlet plug hole 3 and the sampling end plug hole 4 is plugged into the plug to seal, the bottom of the plug hole 3 at the sampling end is provided with a sampling hole 5, the bottom of the plug hole 4 at the sampling end is provided with a sampling hole 6, and the embryo holding chamber 7 is provided directly below the sampling hole 6, and the culture unit main body 1 An embryo culture chamber 2 is provided, the embryo culture chamber 2 is connected to the sample inlet 5 through the sample inlet channel 8 , and the embryo culture chamber 2 is connected to the embryo accommodation chamber 7 through the sample outlet channel 9 .

[0026] In this embodiment, the main body 1 of the culture unit is made of glass, and any other transparent material that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com