A heating tube support for a drum washing machine and the drum washing machine

A drum washing machine and heating tube technology, applied in the field of washing machines, can solve the problems of impact, impact of outer cylinder strength, unfavorable production and assembly of drum washing machines, etc., achieve high strength, save screw screwing time, and ensure the effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

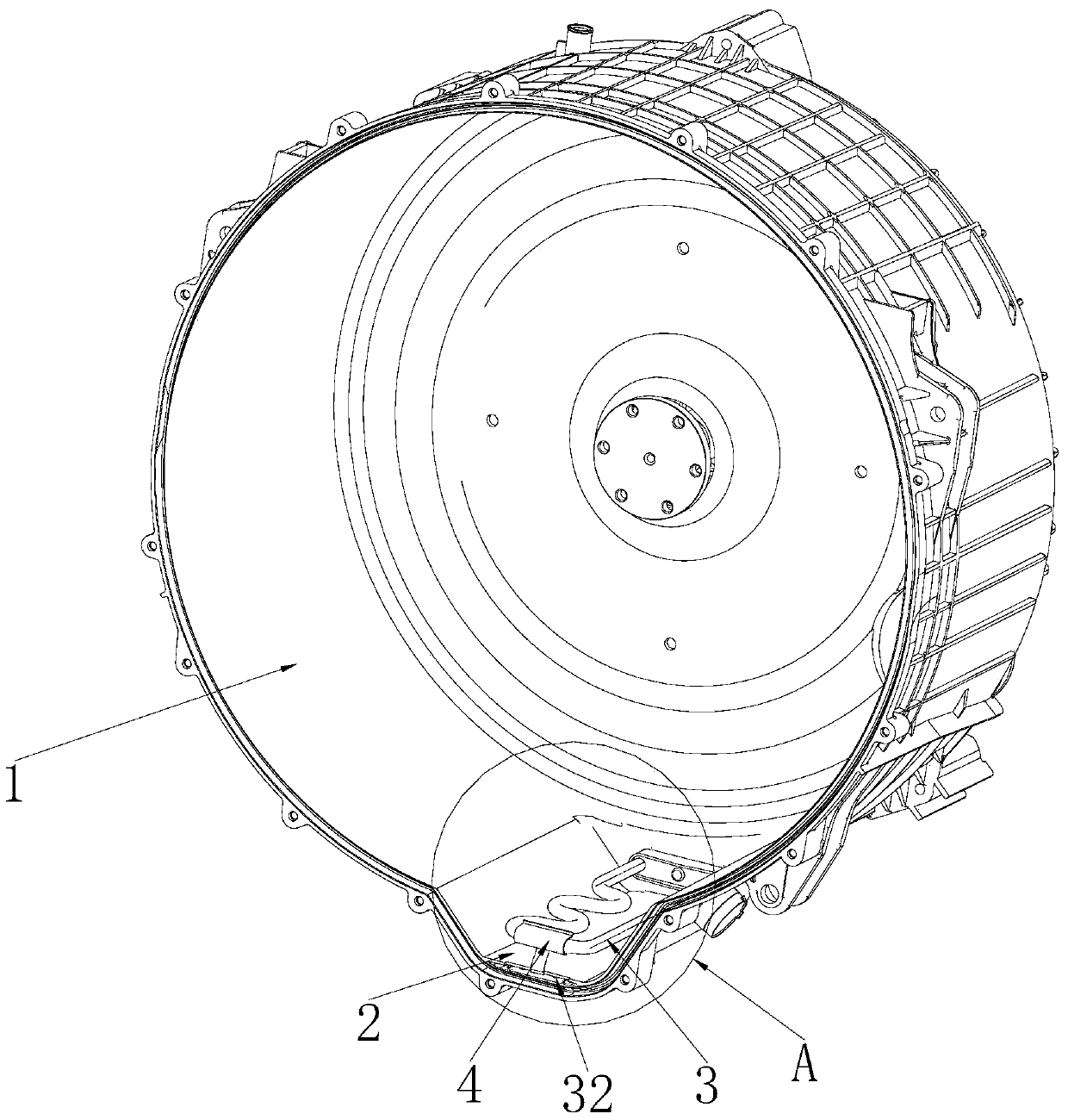

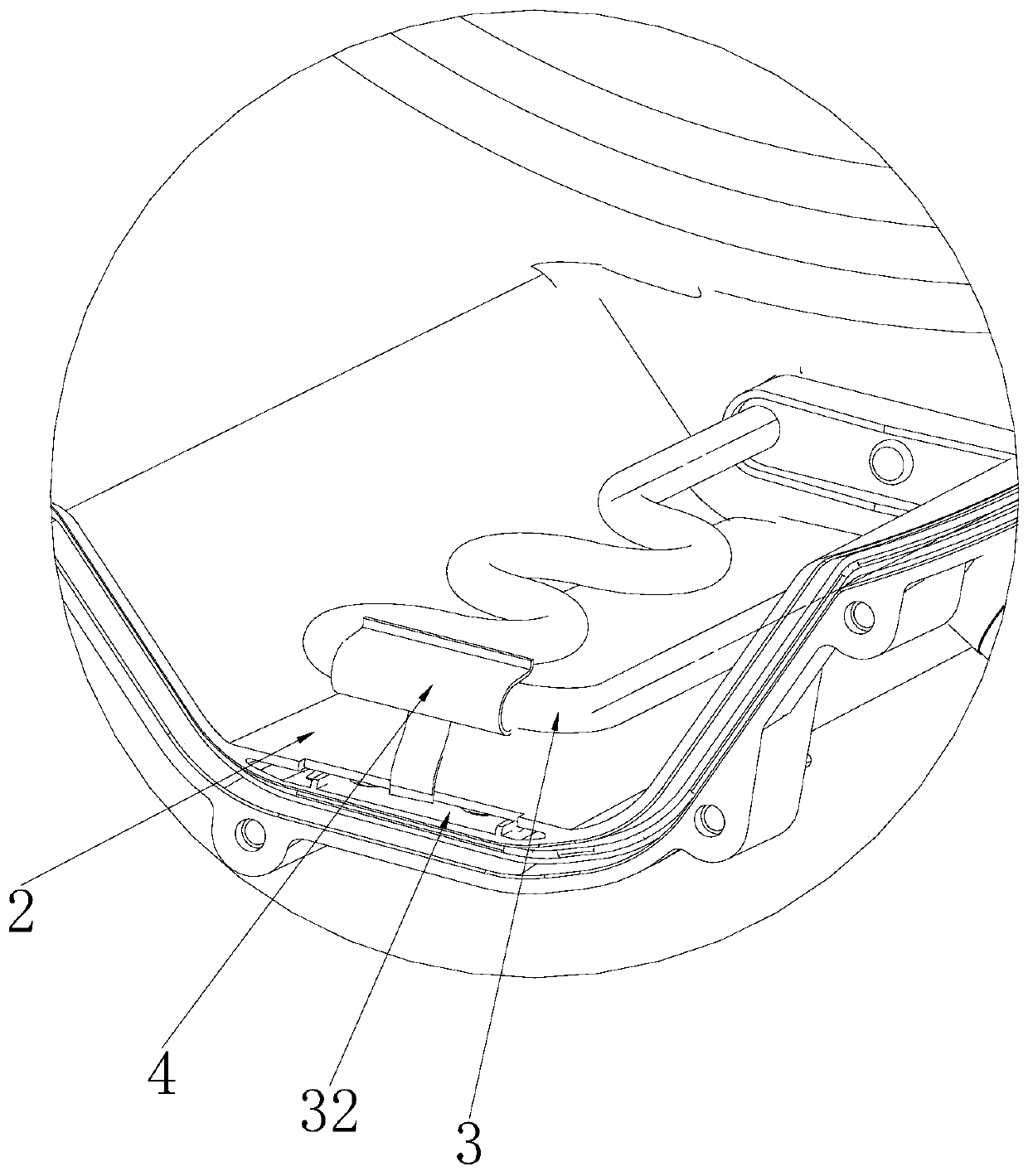

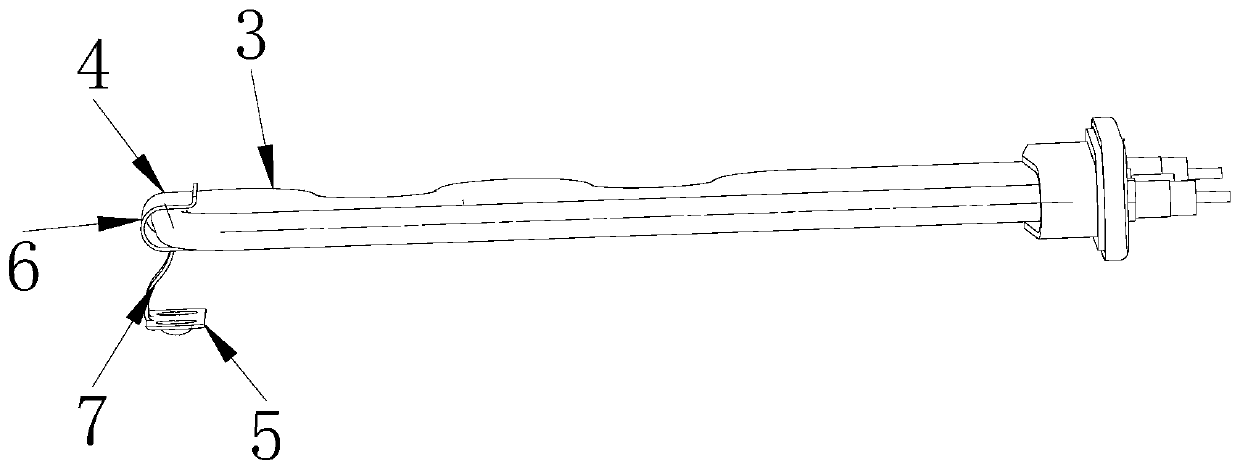

[0026] Such as Figure 4-6 As shown, the heating pipe support of the drum washing machine according to the present invention, the heating pipe support 4 is composed of metal sheets, including the installation part 5 connected to the outer cylinder 1 of the washing machine, the clamping part 6 connected to the heating pipe 3 and used for The connection part 7 connecting the installation part 5 and the clamping part 6, the clamping part 6, the connection part 7 and the installation part 5 are arranged from top to bottom, and the connection is smoothly transitioned. The heating pipe support 4 has a certain elastic deformation, which can overcome the problem that the heating pipe support 4 and the heating pipe 3 cannot be matched correspondingly caused by the installation error in the vertical direction caused by the installation of the heating pipe 3 or the manufacturing error of the heating pipe support 4. It can also prevent the heating tube 3 from being damaged by the rigid he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com