Buried rainwater shunting system

A diversion system, buried technology, applied in waterway systems, water supply devices, drainage structures, etc., can solve the problems of water resources waste, increased processing difficulty, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

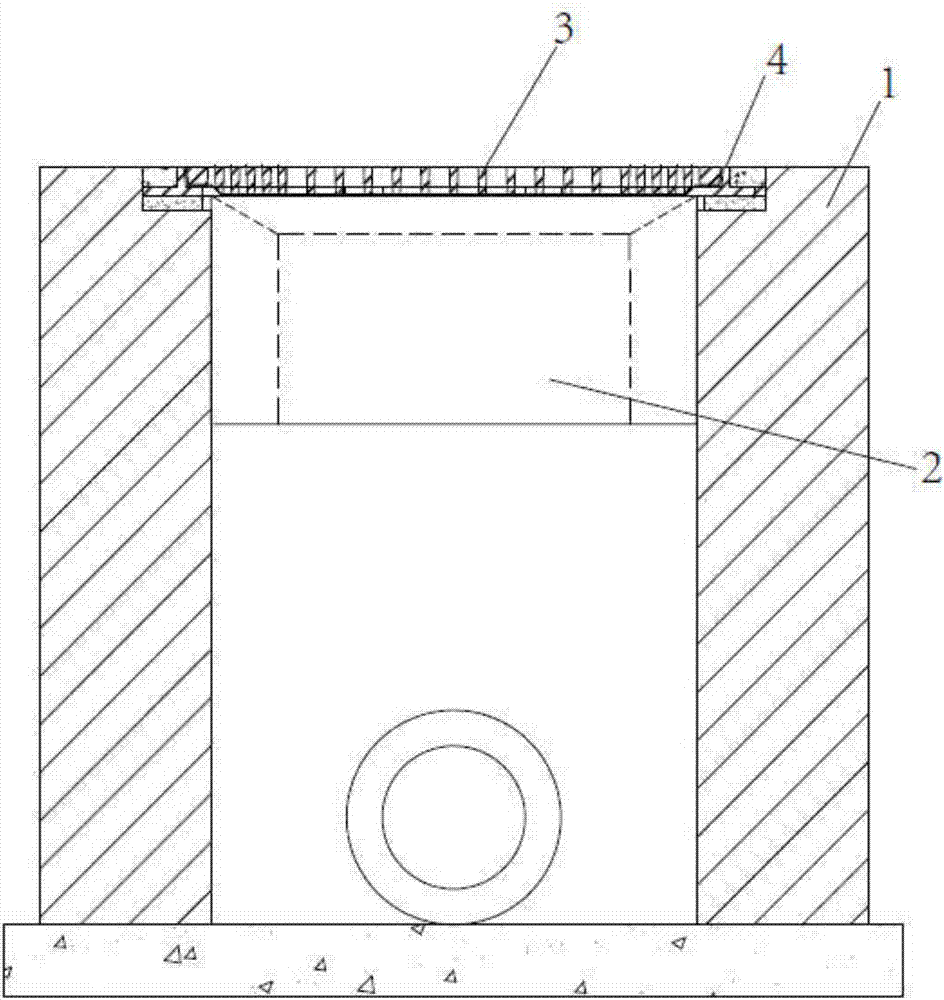

[0032] refer to figure 1 As shown, a buried rainwater distribution system,

[0033] Well 1, a rainwater diversion device 2 is installed in the well, and a rainwater grate 3 is arranged above the rainwater diversion device. The rainwater grate is fixed on the top of the well through the well ring 4; The device can separate the impurity leaves from the rainwater. It collects the rainwater and discharges it. The impurity leaves flow into the well without affecting the original design and function of the well. It is also suitable for the installation of the existing well.

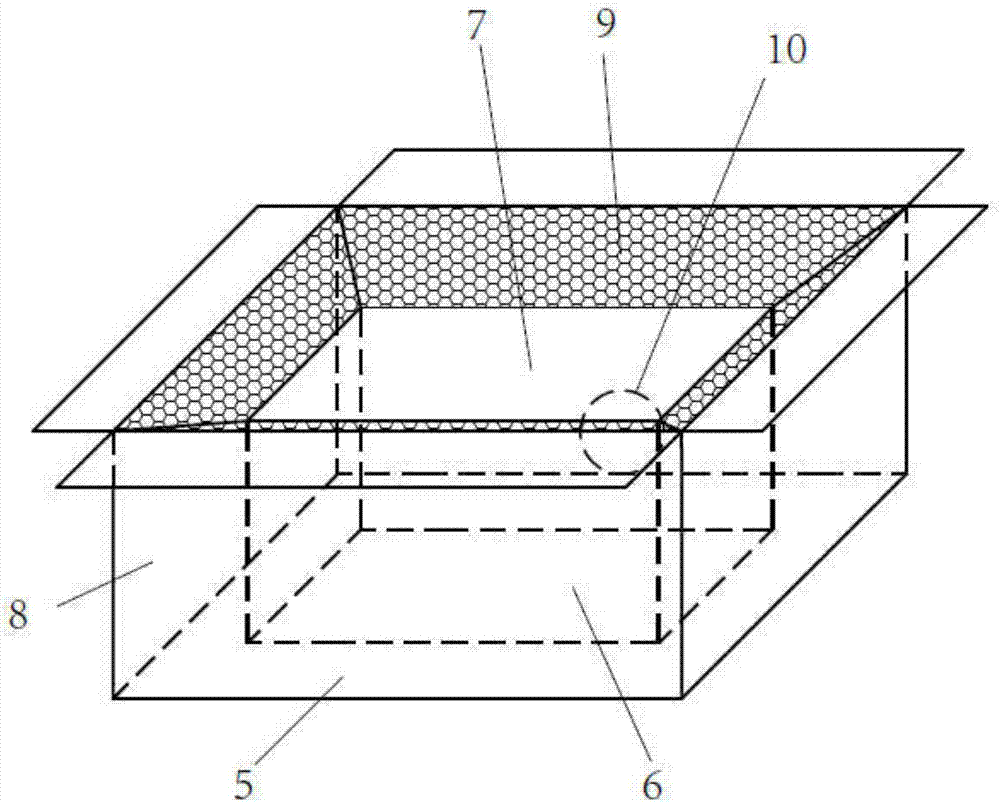

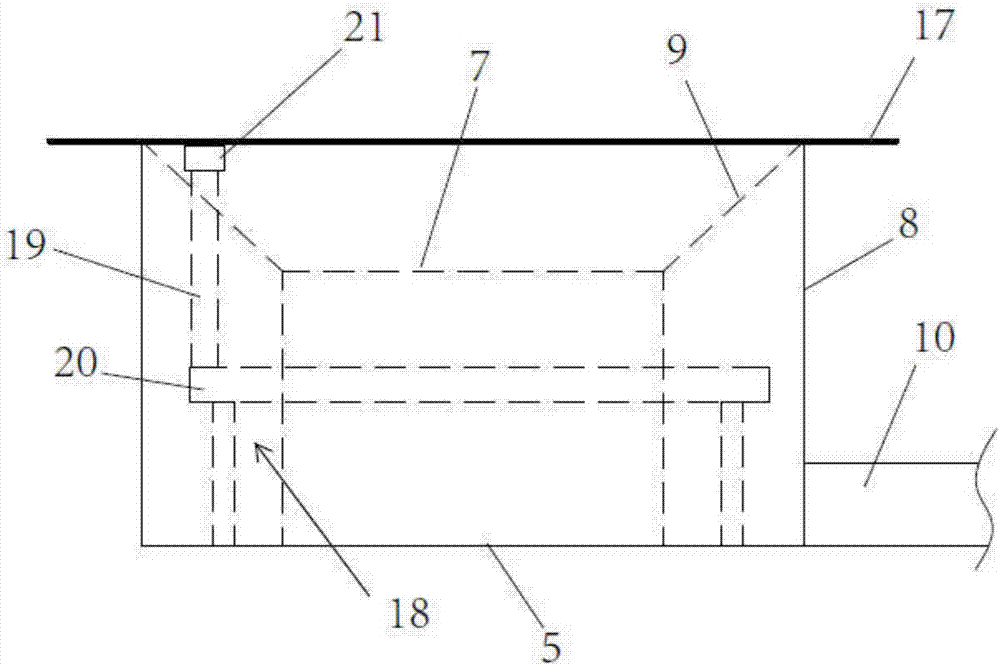

[0034] refer to Figure 5 to Figure 8 As shown, the rainwater grate includes a grate body 11, the grate body is provided with a first mesh area 12, the first mesh area includes a number of evenly arranged first rainwater slits 13, and the periphery of the first mesh area is located in the water inlet direction. The grate body is also provided with a second mesh area 14, the first mesh area includes a number o...

Embodiment 2

[0043] The difference between Embodiment 2 and Embodiment 1 is that the second rainwater passage slit is arranged on both sides of the first mesh area, which only needs to be arranged on the side where the rainwater enters. In the figure, it is designed when there is rainwater on both sides. The body of the grate can also play a drainage role.

Embodiment 3

[0045] The difference between Embodiment 3 and Embodiment 1 is that the width of the second rainwater slit is 5mm, the height of the spoiler protrusion is 2mm, the second rainwater slit width is small, and the possibility of impurities entering is even smaller, making the filtering effect Improvement, the spoiler protrusions block to ensure that rainwater will not directly flow through the second rainwater slit with a small diameter, thereby reducing the inflow of rainwater.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com