Smooth blasting method for controlling flatness of profile surface for underground chamber

A technology of smooth blasting and underground chambers, which is applied in the fields of engineering blasting and rock mechanics, can solve problems such as engineering construction losses, poor straightness of the contour surface of underground chambers, insufficient research on the mechanism of smooth blasting, etc., to avoid Effects of over excavation and under excavation, improvement of construction quality, and protection of life and property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific examples.

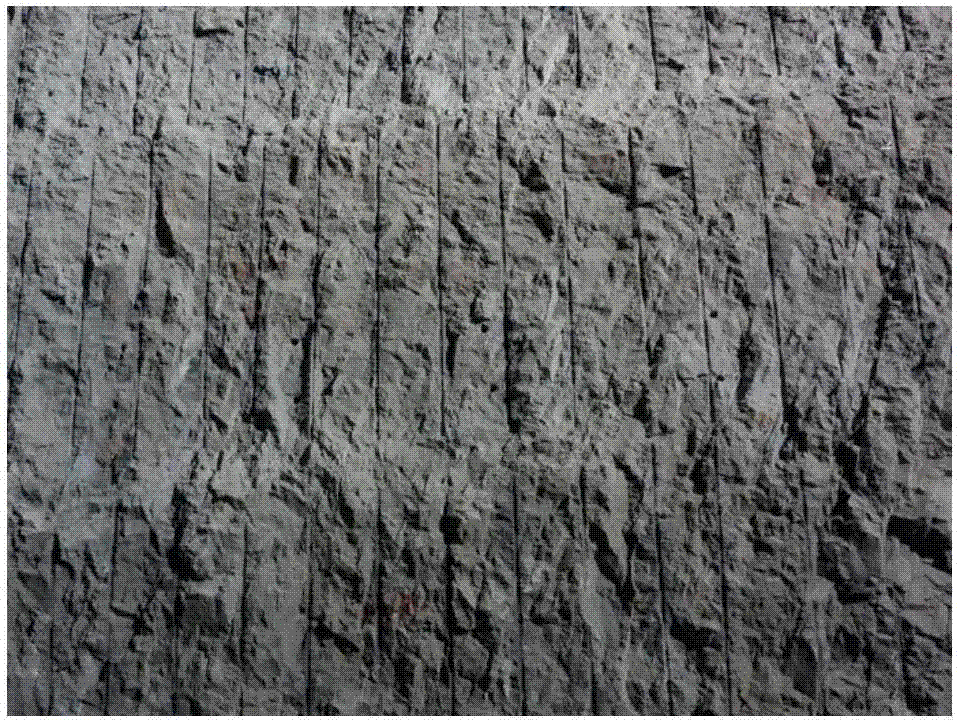

[0035] Part of the chambers of the main and auxiliary powerhouses of an upgraded Jixi energy-storage power station due to poor surrounding rock conditions and some specific parameters of the surrounding blastholes in actual construction do not match the actual construction, resulting in uneven excavation contours of underground chambers. In order to improve the contour In order to improve the leveling quality of the surface, starting from improving the blasting plan, improving the drilling quality, and strengthening supervision, etc., the phenomena of over-excavation and under-excavation in underground chambers were reasonably controlled and reduced.

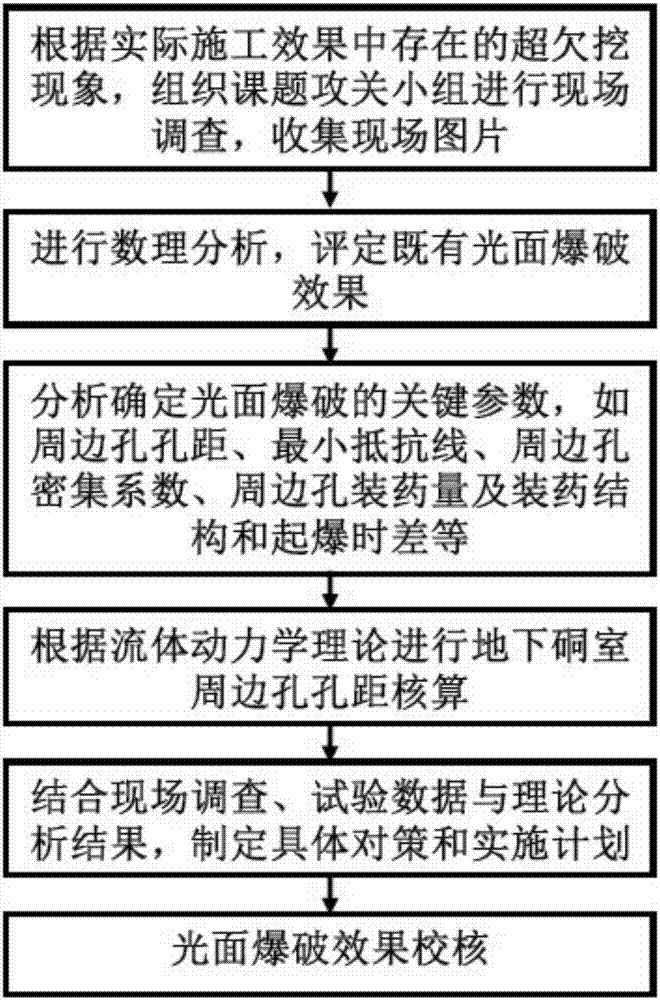

[0036] Such as figure 1 As shown, a smooth surface blasting method for underground chambers that controls the flatness of the contour surface includes the following steps:

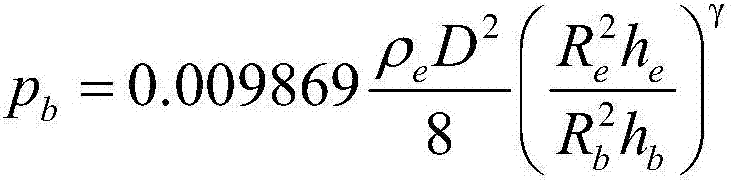

[0037] (1) According to the phenomenon of over- and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com